My afternoon tug pilot slot today was cancelled, on the grounds that the morning crew tried to get a glider out to the launch point, and promptly got it bogged down in the mud half way there. Yippee, workshop time beckons. I thought I'd make a start on drilling and profiling all the rear spokes for my traction engines on the CNC mill. I fired up the CAM program, created the code, and went into the workshop to set the new tool table, set up a fixture and set the work co-ordinates. I thought I'd better do a quick 'air' cut, just to make sure the drill was going to clear the clamps. First run the spindle starts and then stops. Second time around it never started, although the X, Y and Z axes all moved perfectly each time. What the *****!

Therein followed a close examination of the code and individual G & M codes. All looked fine, and it was consistent with a previous CAM program for drilling that worked perfectly. Conclusion, there's summat wrong in t'mill.

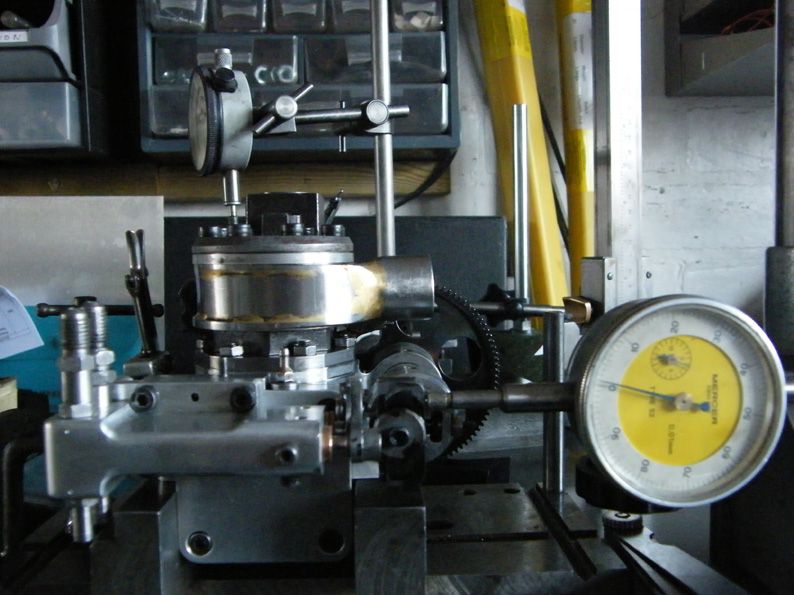

Poking about inside the control cabinet and measuring assorted voltages on the emergency stop lines and contactors according to the troubleshooting guide in the manual didn't raise any issues. Following one of the key rules of circuit debugging I then attempted to break the thing properly by pushing and pulling various bits. Bingo, pushing on some relays on one of the PCBs made the spindle run! Let go and it stopped. Modulate the push force and the spindle speed varied in sympathy. That makes some sort of sense, since the wires on the nearest connector are to do with spindle speed feedback. The crimps on these wires seem ok, taking each one out and giving it a tug, but in my experience with crimps that's not a reliable guide. So most likely I've got some dodgy crimps on the speed feedback, or possibly the PCB itself has a dodgy solder joint or broken track.

The next move is to get some suitable bootlace crimps and remake the said crimps to see if that cures the problem.

Oddly enough I had some speed and spindle issues a couple of months ago, which seemed to be resolved, as I've used the CNC mill quite a lot in the last couple of weeks with no problems. I put the issue down to condensation in the very cold workshop as the spindle seemed to run fine after the machine had been on for a while. It would seem that I might have been wrong.

Regards,

Andrew

Muzzer.