G'day.

Today was one of 'those' days. Hot in the workshop, 85° outside. Decided to cut a

block of aluminium for a project when click, the bandsaw blade broke. Out with a

spare, could not get it to stay on the wheels. H'mm, out with the tape measure,

10mm longer than the makers specs (3 others were the same). So the blades were

cut, 5mm removed, the ends chamfered.

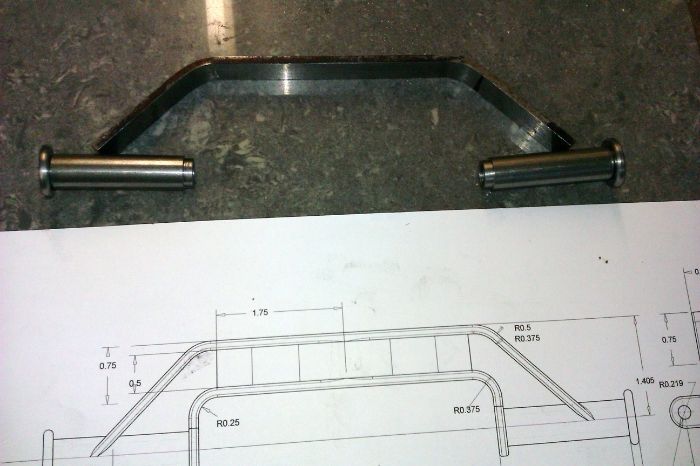

Next to hold them for brazing. A jig was made from a piece of angle iron with two

pices of steel packing band screwed to it as guides. Then drilled & tapped 3mm to

take some screws & flat washers to clamp down on the blade. After aligning the

blades with a tiny gap,a small pice of silver solder was cut (the flux flaked

off) and laid over the gap with the bits of flux). Out with the gas torch, played

the flame on it from below until the flux melted and the solder flowed into the

joint.

At this stage the fumes set off the workshop smoke alarm, my neighbours came to

investigate/save me and so after trying the new blades for size I gave up.

Cutting the aluminium tomorrow, 90° predicted with 104° for Thursday.

Yep, one of those days

* Danny M *

Muzzer.