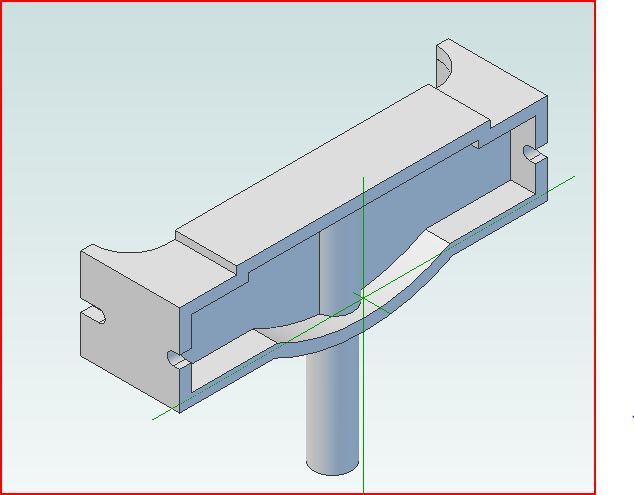

No pics but pulled the slotting head off the Bligeport clone and stripped it down.

Fitted it unused when the mill was new earlier this year but first time in use it sounded like it had no bearings in it.

Sure enough the bearings, all 4 were clapped out. Rang the rewind company who buy tens of thousands of pounds worth of bearings every year and pleaded poverty and they gave me 4 new bearings.

Second bit of luck was this head is grey and not very pretty, Warco supplied some paint rattle cans when I bought the machine but did say the commercial size machines are a different shade to the hobby machines. However a different shade of green is better than crap grey.

Rattle canned the motor and there was a big difference, just then the paint sprayer from the body shop across the road called in wanting a stainless nut for his steering damper on his racing bike.

Explained the problem and he went back, came back over with this fancy camera which you place onto the machine, press the trigger and it gives you the paint code.

So once the new bearings are fitted he's going to pop over and waft it with some hi-build two pack, only costs £125 per litre !!!

Muzzer.