The only machine mounts I could find (and there were quite a few of them to choose from) all had short fixing studs, so I had to make up some female bolts (looks like a bolt with a female thread at the end) so they could fit on my Bridgeport clone milling machine. And the front 2 mountings on the base of the machine are hollow, so I also had to make up a couple of spacers to pass the load from the feet up to the inside of the machine base, 4" from the ground. Nothing's easy!

Worked out nicely and after a bit of trial and error, the machine is finally on the level and a lot more stable.

Next day (Sunday), I made up a small block to hold my 2 drawbars on the head of the milling machine. The previous holder I mounted on the side of the machine near the knee works fine but each time I want to change from the drilling chuck to the collet chuck I have to swap the drawbars over. Sounds simple enough but doesn't speed things up keeping the spare at the other end of the machine.

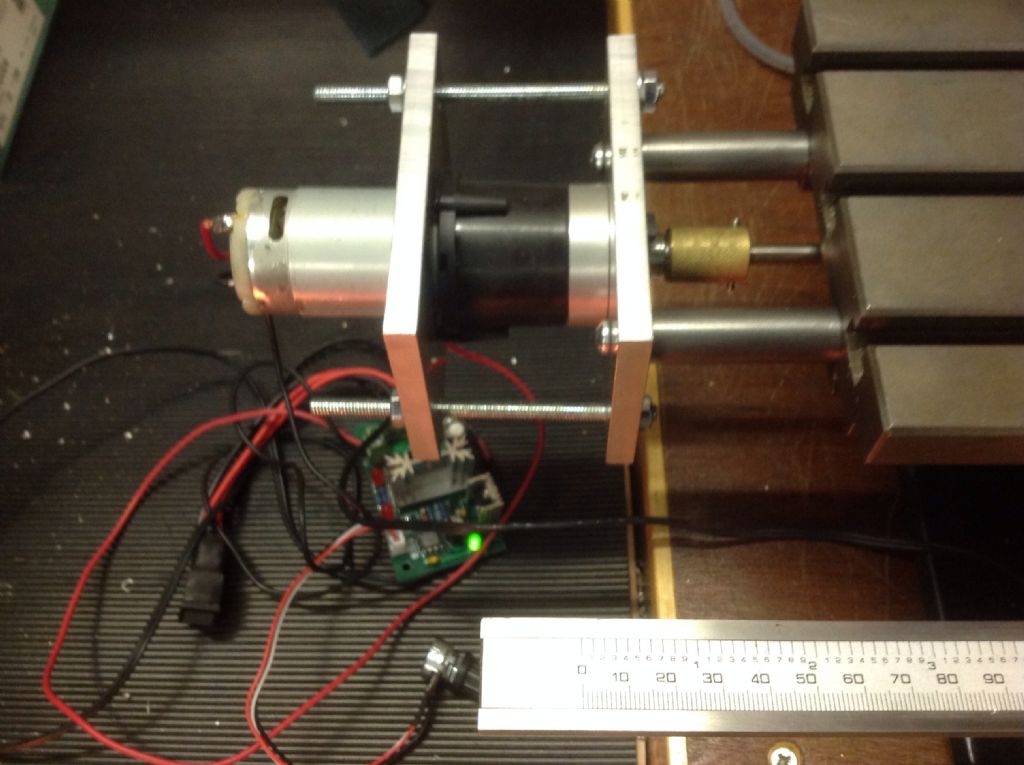

This is what it looks like in use. The spare drawbar is literally only inches from where it is needed now, ready to be swapped over:

Didn't take long to make but should save a lot of time in the long run. Been meaning to do this for months…..

Muzzer

Muzzer.

which is stage 1 of the insulation before the lathe goes in.

which is stage 1 of the insulation before the lathe goes in.