Wait for it everyone . . . .

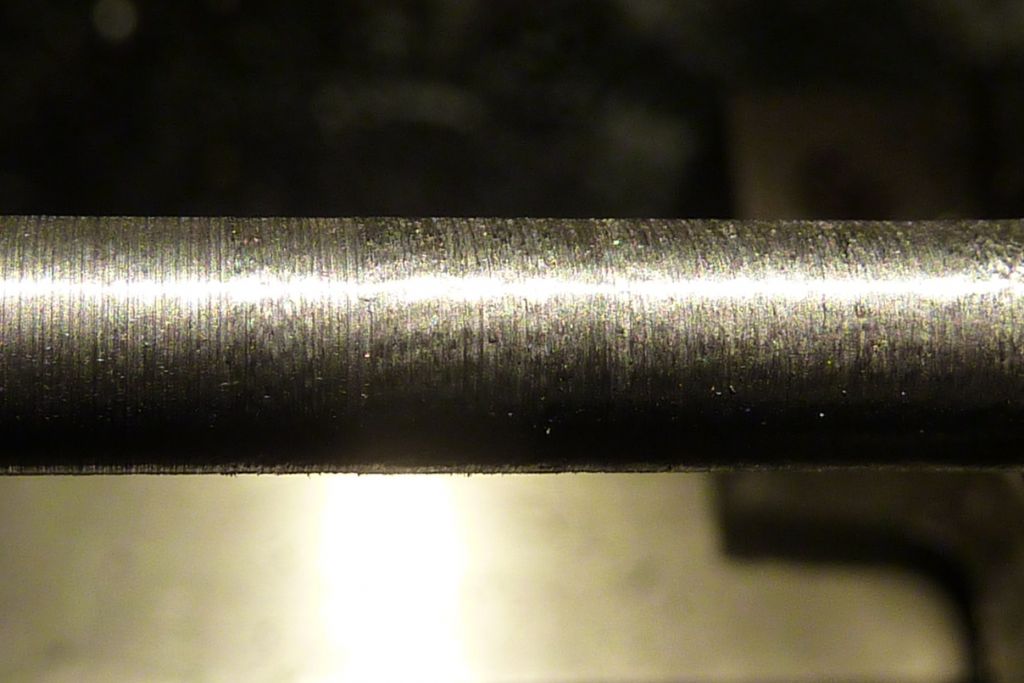

I've finished repairing the lathe!

What would have been a couple of days work at my youthful best, has taken flipping ages, not withstanding treatment and the horrible winter virus.

If someone had said the 'silver lining' thing at the time I discovered that i had bent the shaft, they would have received a biff. (Can remember my Dad searching for a length of 2×4 after some yoofs threatened to pin his ears back, with Mom & I talking him out of the inevitable contretemps. 4-1 odds not too good)

However, I did discover the total lack of any oil being able to get to any bearing surface or gears in the Apron, so that took some while to rectify, so 'silver lining' there definitely was.

Spent yesterday putting everything back together again, and adjusted the Cross-slide leadscrew nut to give a couple of thou play. Will adjust again later, as its very easy to do.

Everything appears to work as precious, but I still need to connect the power feed shaft to see if the worm gears mesh properly, as the gunmetal? one had the tops of a couple of teeth chewed up.

I WILL be using 5mm brass tube in place of spring pins in both the Leadscrew and Feed Shafts, and if these fail too easily, drilled/waisted brass pins.

Will be doing a new thread on what and how I did everything, with photos once I've annotated them.

I can now confirm that taking the Apron off of this type of lathe is a doddle.

Now to fix the shaper.

Geoff – Feeling rather chuffed.

Muzzer.