Picked the first round of plums, now quartered, stoned and in the freezer ready for a hot plum crumble in the depths of winter.

Picked more blackberries, made a jelly – eaten half of it already.

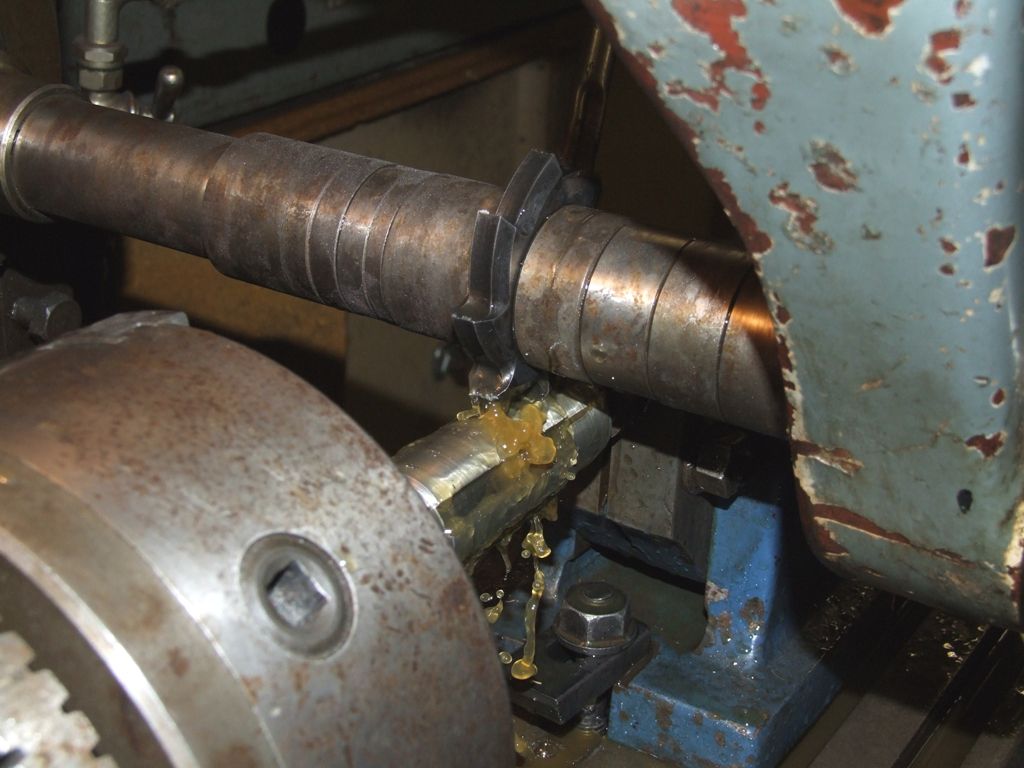

Cut a keyway, and cleaned up the edges, on my home made spline cutter, now ready for hardening and tempering:

Massive clear up on lathe and the floor around it. Moved over 20kg of cast iron and steel swarf. Gave the lathe a good clean and oil, including taking tailstock off to clean underneath.

Swung ram on vertical mill to swap slotting and milling heads.

Experimented with aluminium specific inserts and higher feedrates. Interesting, still some birdsnesting of the swarf, but I did find roughing and finishing cuts where the swarf was well behaved.

Made a blank for the worm on my traction engine steering gear from an offcut of delrin to test out the hand written G-code, when I get round to buying a 3mm endmill. I feel a trip to the local tool warehouse coming on! I need the 3mm cutter, some drills and spot drills to replace those I've badgered, some silver steel and some slideway oil. Oh, and some threading inserts for Whitworth 20tpi and 32tpi.

Cleaned up some collets and die holders for the Britan lathe; put same on Ebay, as they're duplicates.

Plus a few other things.

Wrote this missive.

Now off to cook supper.

Regards,

Andrew

Muzzer.