I actually managed to do some home engineering this weekend; largely because it rained non-stop on Saturday and most of Sunday.

Saturday: Finally got the step ladder and a set of folding steps hung from the rafters in the workshop, so that I don't keep tripping over them when I don't need them. Fixed the lathe, yipeeeeee! Ever since I did a rush turning job a couple of weeks ago for a client, and a long spiral of swarf disappeared under the headstock, it's made a clicking noise that gets worse with higher spindle speeds, and is related to spindle speed. I took the cover off the headstock gear box but couldn't see anything amiss, no missing teeth, which is a relief. The headstock is sealed, as it uses splash lubrication from an oil bath in the bottom, so I couldn't see how the swarf could have got in, but you never know. I then dismantled the splash guards to get to the two V-belts from the motor to the headstock. Nothing evident there either; although the belts looked a little tatty, so for the sake of a few quid I'll buy and fit a couple of new ones. The existing ones are at least 10 years old. Further careful listening seemed to indicate that the noise was coming from the gear train from spindle to powerfeed gearbox. I'd already extracted some swarf from here, but dutifully undid everything again. After inspecting each gear for missing teeth, there was the problem, a couple of bits of swarf embedded in one of the tufnol intermediate gears. Removed them with a poking device I made at school ahem years ago, and magically the lathe is quiet again, even on top speed.

Made a new washer in silver steel for a self-releasing tap holder for the Britan repetition lathe so that the dog clutches work correctly.

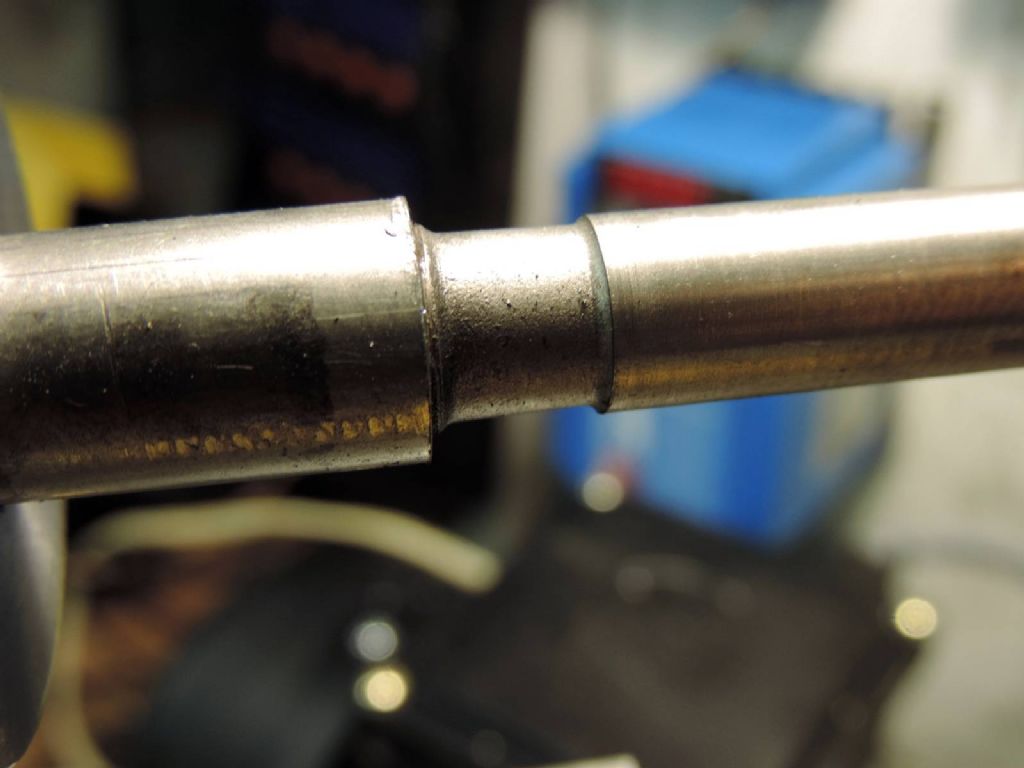

Hacksawed through six inches of half inch gauge plate to make a blank for a milling cutter; also made a mandrel to hold said blank to turn the outside and ultimately mill the cutter shape.

Sunday: Faffed about on the computer and then spent the afternoon milling out said cutter. It's for cutting the splines on the crankshafts for my traction engines. Here's the progress so far:

Just need to draw file to get rid of the machining marks, cut a keyway and harden and temper it. Also stripped down, cleaned and re-assembled two more self-releasing tap holders.

Monday: Went up to gliding club near Corby and flew the tug for the day; a Wilga as seen in my Odds 'n' Sods photo album. And wrote this missive.

Regards,

Andrew

Muzzer.