What did you do today? (2013)

What did you do today? (2013)

- This topic has 920 replies, 132 voices, and was last updated 31 December 2013 at 20:23 by

Muzzer.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- The Decline of Model Engeneering Workshop

- Boiler Examinations: 7-yearly External Query

- Vibration and exploring the Fast Fourier Transform with CAD

- George Thomas retractable slide for the myford.

- BlueBerries

- Air source heat pumps

- 3 1/2″ gauge LMS Jubilee 4-6-0

- Oil grooves for bushings?

- House painting

- FB2 Clone – aligning the column

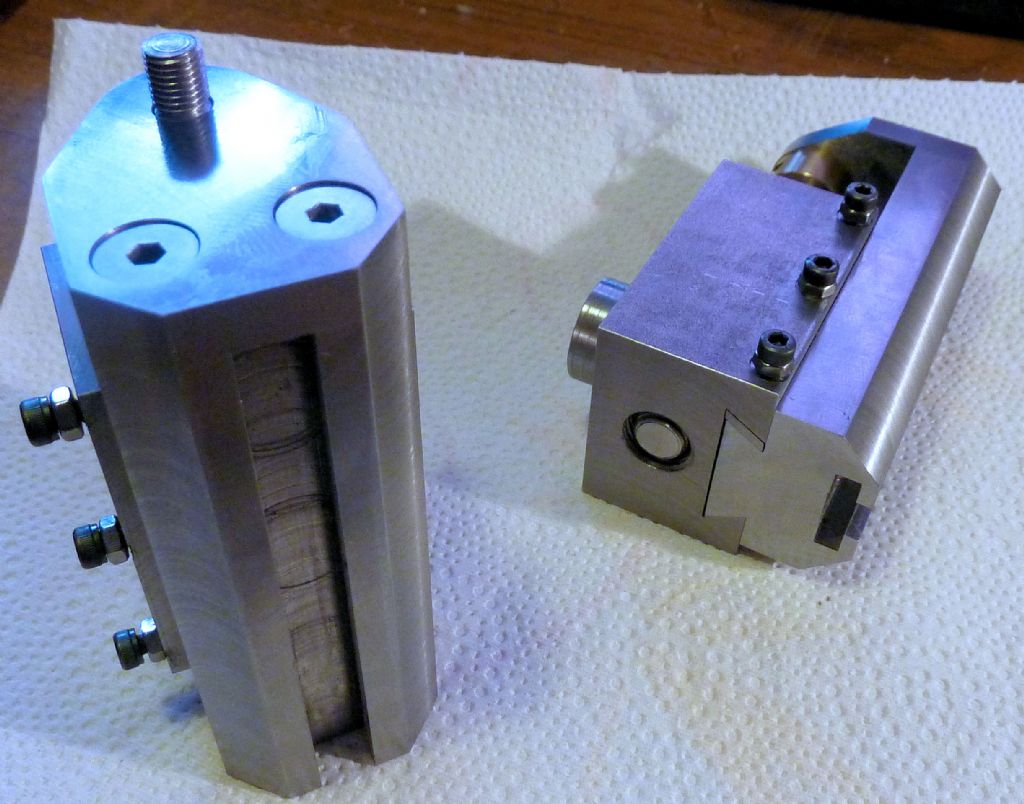

which sort of lives up to some of the hype), and routing finger grooves in some thicker acrylic offcuts to make handles. I used a woodworking router bit in my mill. A few minutes on belt sander, to get more or less square, then a quick file to get more or less smooth, then onto the polishing wheel and they are ready for glue.

which sort of lives up to some of the hype), and routing finger grooves in some thicker acrylic offcuts to make handles. I used a woodworking router bit in my mill. A few minutes on belt sander, to get more or less square, then a quick file to get more or less smooth, then onto the polishing wheel and they are ready for glue.  . Spent a couple of hours in the workshop earlier this evening.

. Spent a couple of hours in the workshop earlier this evening.