Hi All,

I thought that I'd better add to this thread. I suffer from a bad back after a serious motorbike accident years ago so a pain free day is a bonus and I tend to make the best of them.

Had a varied day today, traditionally we always do our weekly supermarket shopping on Saturday morning so off the local Morrisons at 8:00. Had some maintainance to do so cut back a rampant Wisteria I am trying to kill off – I had sprayed it with glyphosate 4 weeks ago (and managed to kill off a bit of the lawn as well  . Then cut the lawns.

. Then cut the lawns.

After lunch decided to tackle a dicky Z Scale on my milling machine – a variation of the Weiss – equivalent to the Warco WM18. Stripped it off the machine, disassembled it, cleaned it and in the best Haynes manner 'reversed the process' – seems to have worked so far (need a fingers crossed emoticon here). I was amazed by the stainless steel body. The groove for the slider appeared to have been cut with a blunt cold chisel by a blind rice farmer. All pictures clickable(except Milling cutters).

Got down to some serious work and tried an assembly of my part refurbished Grinding rest which I managed to rescue from my garage fire. – remember this?

I have de-rusted the main components and reassembled it after some fettling, the lower parts are finished. I just have to work on the upper section and make new knobs and handles but it actualy works well using a common handle in each clamping screw..

I'm also making the accessories again as most were lost in the debris. Started off by cutting a couple of lengths of rescued steel

and

A bit slow as I have no mechanical saw and neeed to use my trusty hacksaw which originally belonged to my grandad. Like me, its a bit rusty and worn round the edges but works ok.

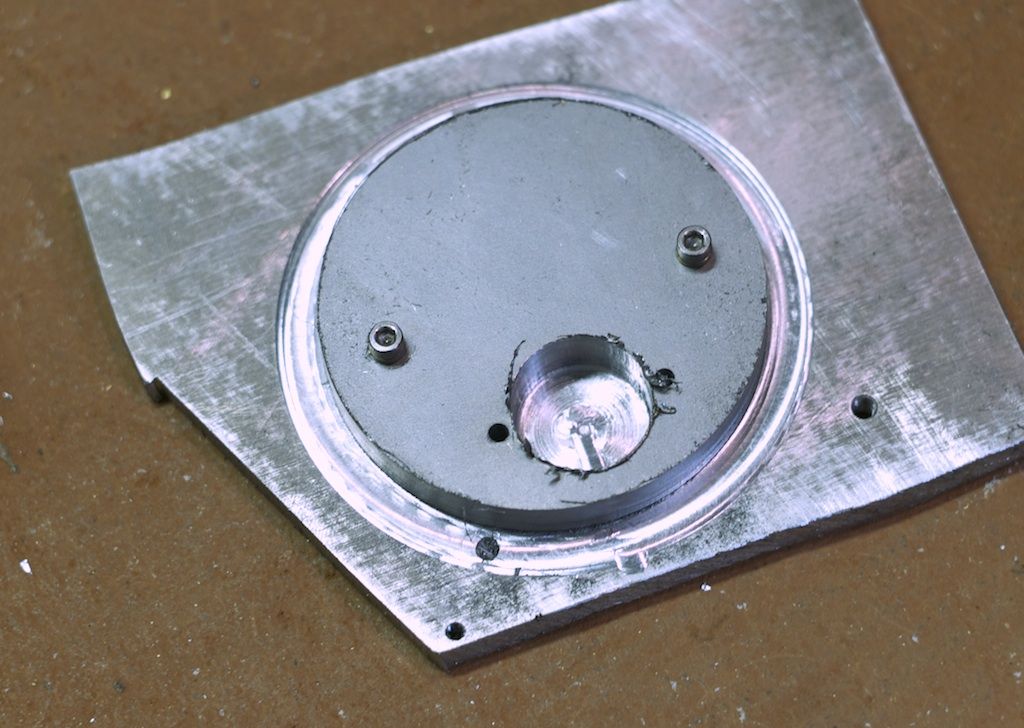

I cleaned them up a bit, removing the rust manually as my acid bath needs replenishing (it's outside – never in the workshop. As I have broken a small tap some time ago and needed to tap a few holes accurately I made a simple tapping guide and turned up a bit of scrap. marked it out and drilled it.

I intend to also use it for BA taps hence the other centre punch marks. a simple device, it works quite well,  – seen here in use tapping the square tool holder for the above grinding rest:

– seen here in use tapping the square tool holder for the above grinding rest:

It not only guides the tap vertically but also helps to prevent any tendency to bend the tap due to uneven pressure thus snapping vulnerable ones.

See next post as this one is too long (first time for everything)

Edited By Terryd on 21/10/2012 07:49:13

Muzzer.