It is, Diogenes, it is……

;;;;;;

Today, I took an invitation to view a Marshall Portable Engine under restoration.

This thanks to a friend, Adrian, the engine belonging to a work colleague, Martin.

Progress so far has concentrated on the boiler, with Martin showing us the part-rebuilt inner firebox: he and a friend and project colleague have hand-forged the flanges on the new end-plates, but luckily the wrapper including the crown-plate with its distinctive cruciform strengthening rib formed by pressing, is sufficiently un-corroded to re-use.

That pair of ribs was a Marshall patent feature, avoiding conventional stays, on all its boilers. Garret used something similar, two large corrugations along the crown.

.

Martin, and a friend helping him, also pointed out the replaced lower part, holding two wash-out covers, of the smoke-box tubeplate. The engine had stood in the open for some thirty years, causing the bottom of the smoke-box to become a stagnant pool of rain-water and decaying leaves just right for thinning the steelwork.

The major part of the tubeplate is good enough, with some work, to satisfy the boiler inspector. This plate too has a pressed reinforcing rib across the steam-space area.

The fore-carriage cradle is on the boiler, not smoke-box, so unaffected by the rusted-out smoke-box. That is presently all in place but the hind axle and wheel assembly are in another building to allow access to the firebox.

I asked Martin how he ventilates the shell when grinding and welding inside it. He pointed to a big desk-fan, and explained that standing that in the smoke-box removes the bulk of the dust and fumes; but he also uses ventilated face shields.

.

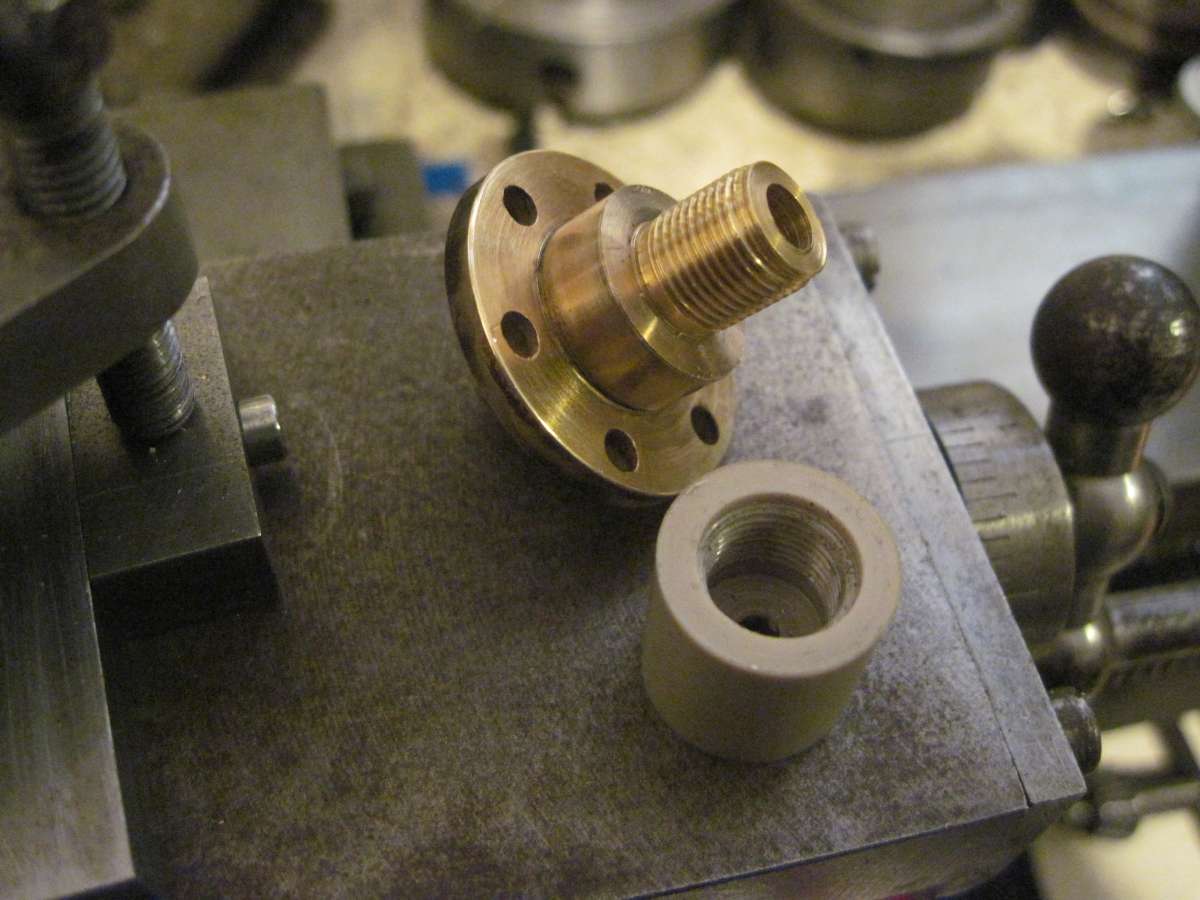

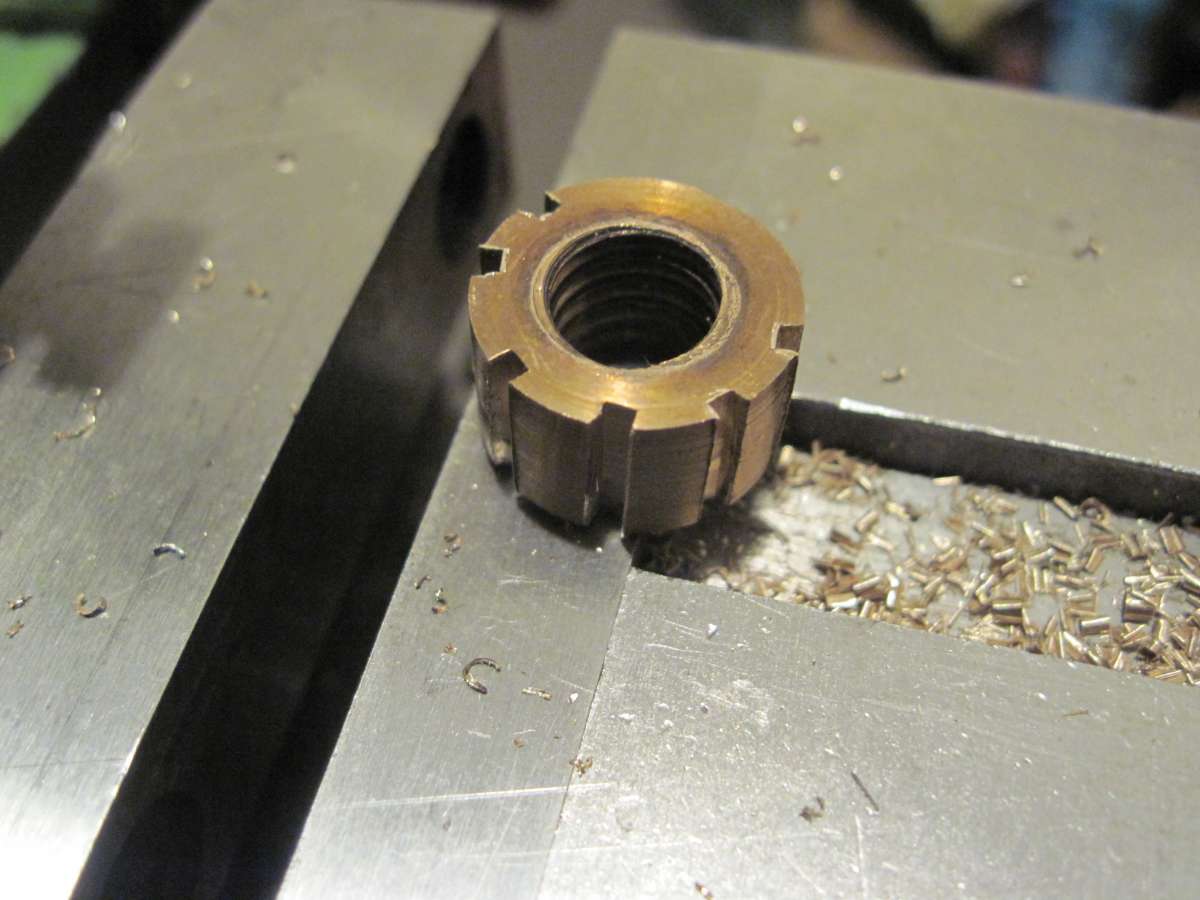

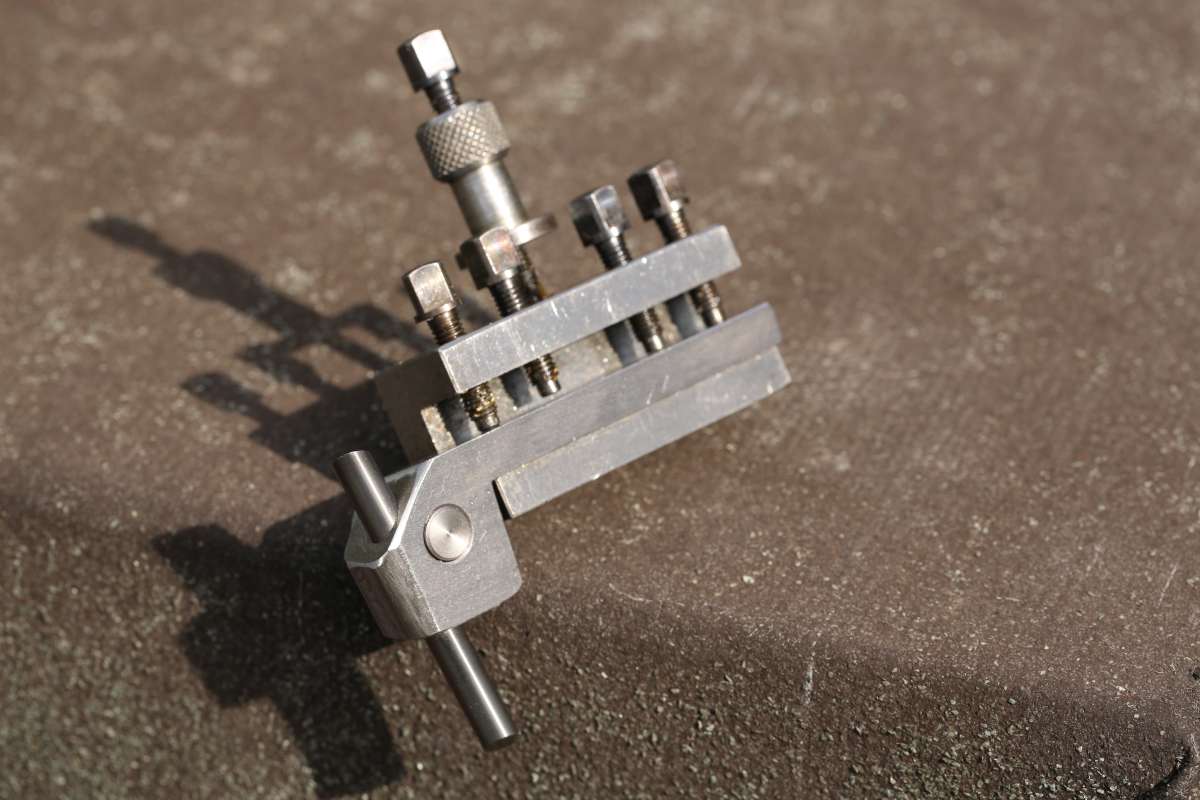

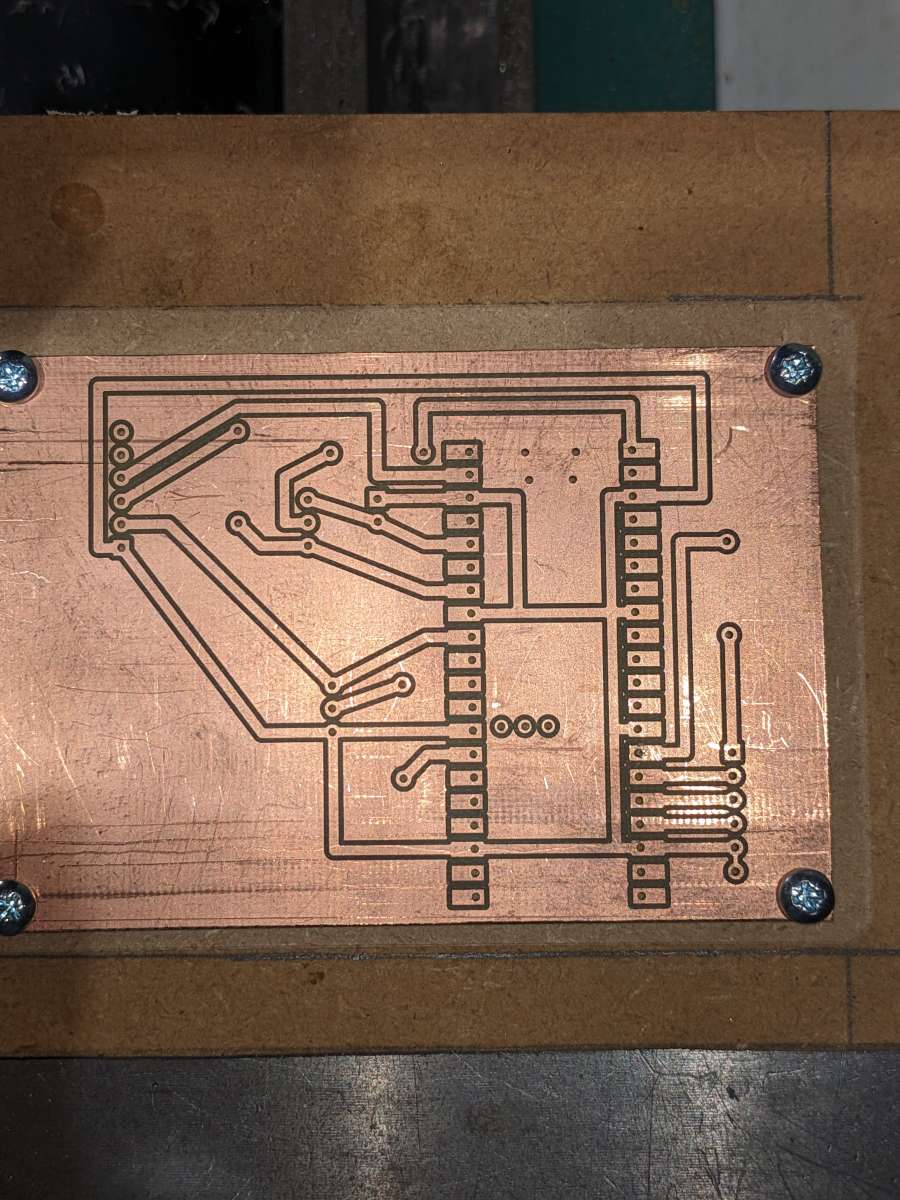

Many rivets in the shell have already been replaced, by manual hot-rivetting. The many threaded stays for the firebox have yet to be made – I spotted a hefty lathe in a gloomy corner of the workshop, along with a roller, bending-press and a universal mill.

Shiny steel around the firebox wash-out holes prefaced a point here, unexpected by me. The original, single-stud, oval covers were made generously loose for the asbestos-cord sealant of the time, now unavailable. The gasket used now is a synthetic rubber material needed a much narrow clearance so Martin has had to build up the mud-holes rims with weld.

Mechanically the engine appears in fair condition though this has yet to be investigated deeply. Martin pointed to the governor, lying nearby, and I saw its bevel-gears are very little worn, but the thin-gauge leaf-springs linking the weights have rusted through.

.

In all it was a very interesting little tour, and I was very grateful to Martin’s hospitality and Adrian for arranging it.

Oh – and Adrian’s own metalworking hobby is at the other end of the size scale: silver-smithing!

……

After this visit Adrian and I repaired unto a garden-centre cafeteria a few miles away, for coffee and buns. Various rusty but intriguing lumps of ancient metal “decorated” its entrance area, and I glimpsed what seemed a large, antique pillar-drill with a rack-feed table, but as I was driving out of the car-park I could afford only a sidelong (longing?) glance!

Dalboy.