Made a remarkably early start! It was 01:10am when I turned off the radio, now on BBC World Service as Radio Four goes to bed at 1am, and locked the workshop

I made the vertical feed-screw for my ‘Stent’ T&C Grinder, from a length of black steel bar that seemed rather unpromising at first but did turn quite well.

I think I had bought the steel for some long-forgotten or even completed work, but sometimes I find stuff from Inpecunious, Hedgerow & Reloved is useless with carbide tools but a very sharp, stone-finished HSS tool will cut it nicely. (More accurately, such steels likely need very specific carbide tips and feeds, not necessarily those that work very well on free-cutting alloys.)

‘

You know how it is –

– Some hours spent teasing the shank down from 5/8-ish inch stock to 0.375″ plus nowt / minus a thou or three for more than four inches length; then using an indexable-tool and HSS chaser to produce 3/8″BSF thread all the way along it to fit a test-nut and you think,

“Phew! That’ll do for tonight! I’ll just turn it round in the lathe so it’s ready for tomorrow….”

… “I’ll just face and centre-drill the end”…..

‘Wight, Portland, Plymouth: South to South West 4 to 5, showers, good…..’

…….”May as well turn that 0.500″ spigot down to 0.375″ diameter for the required length”…

Stand to attention for the National Anthem.

……..”Oh to Hell with the time. Finish the bloomin’ thing!”

.

Then when I held the screw I’d made faithfully to drawing, against the part-built machine, I found the overall length is appropriate but the specified thread length is nearly an inch more than necessary. Grrrr!

Dalboy.

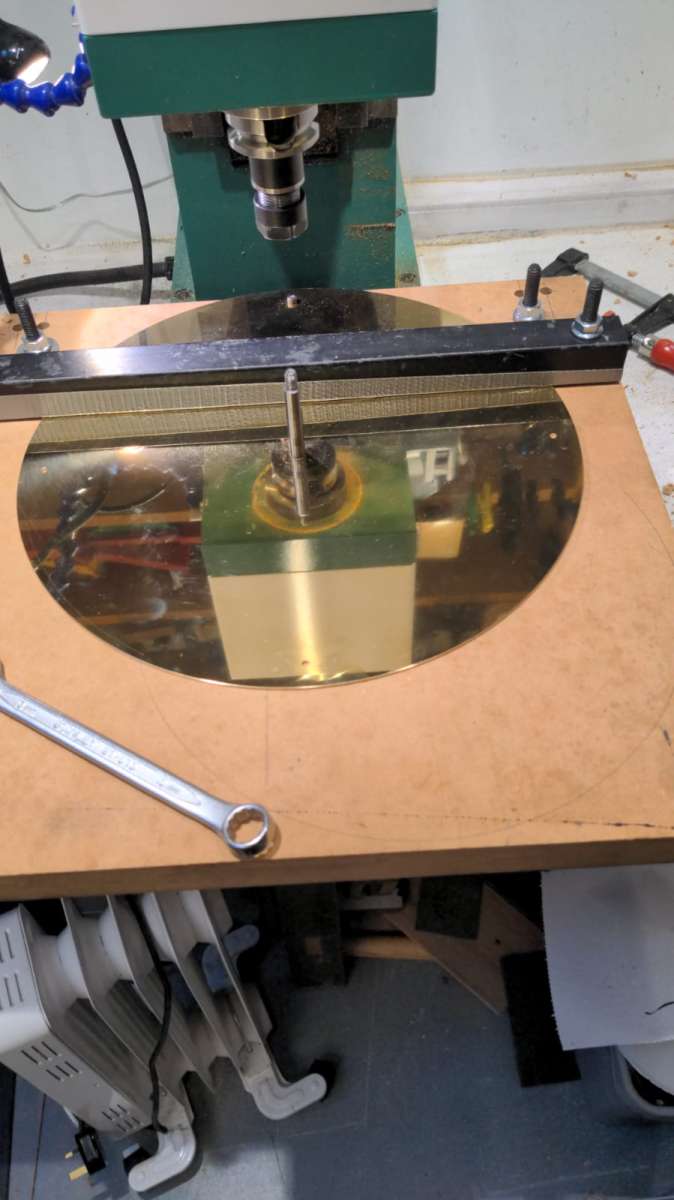

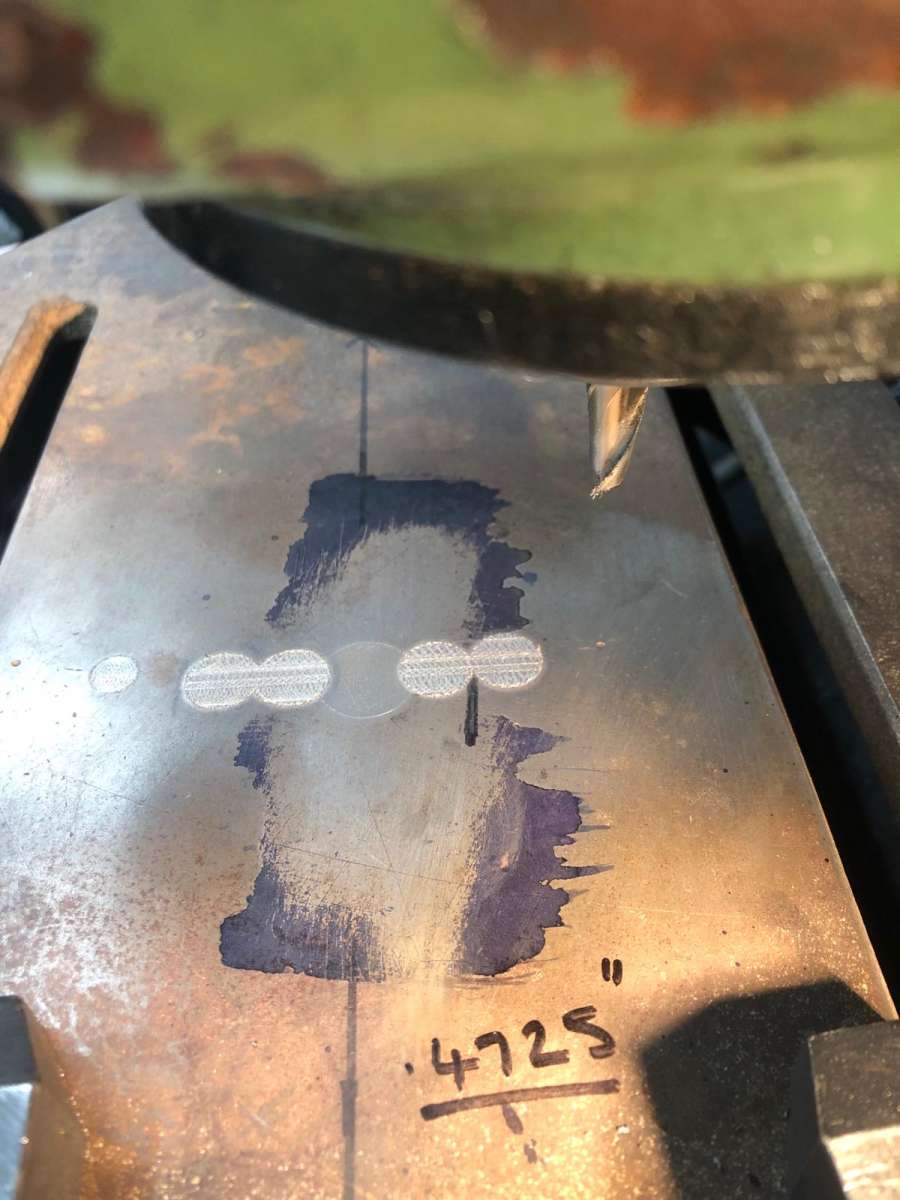

Bought a very cheap Meddings drill from Facebook marketplace , lots of surface rust a smile of shame on the table and the safety collar that fits under the head is cracked, otherwise very little used. The Meddings table shouldn’t have a centre hole, someone had thoughtfully drilled one in, but not central to the table clamp slots. Decided it couldn’t be lived with so spent the afternoon giving the table a little TLC, slot drilled holes 5/16″ deep and plugged with little slugs of cast iron. Slugs went into the freezer for a while and tapped in, machined off as near to the table as I dared, filed and oilstoned flat. Doesn’t look too bad, not perfect but much better than before, pleasant afternoons work. Next job fabricate a new safety clamp, there’s one on ebay for sale, but it’s the same price as paid for the machine!

Bought a very cheap Meddings drill from Facebook marketplace , lots of surface rust a smile of shame on the table and the safety collar that fits under the head is cracked, otherwise very little used. The Meddings table shouldn’t have a centre hole, someone had thoughtfully drilled one in, but not central to the table clamp slots. Decided it couldn’t be lived with so spent the afternoon giving the table a little TLC, slot drilled holes 5/16″ deep and plugged with little slugs of cast iron. Slugs went into the freezer for a while and tapped in, machined off as near to the table as I dared, filed and oilstoned flat. Doesn’t look too bad, not perfect but much better than before, pleasant afternoons work. Next job fabricate a new safety clamp, there’s one on ebay for sale, but it’s the same price as paid for the machine!

![PHOTO-2024-03-31-21-08-26[3819]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/723599/lm8xtk5ctny3k62gg7kxg7cksqchom5e.jpg)

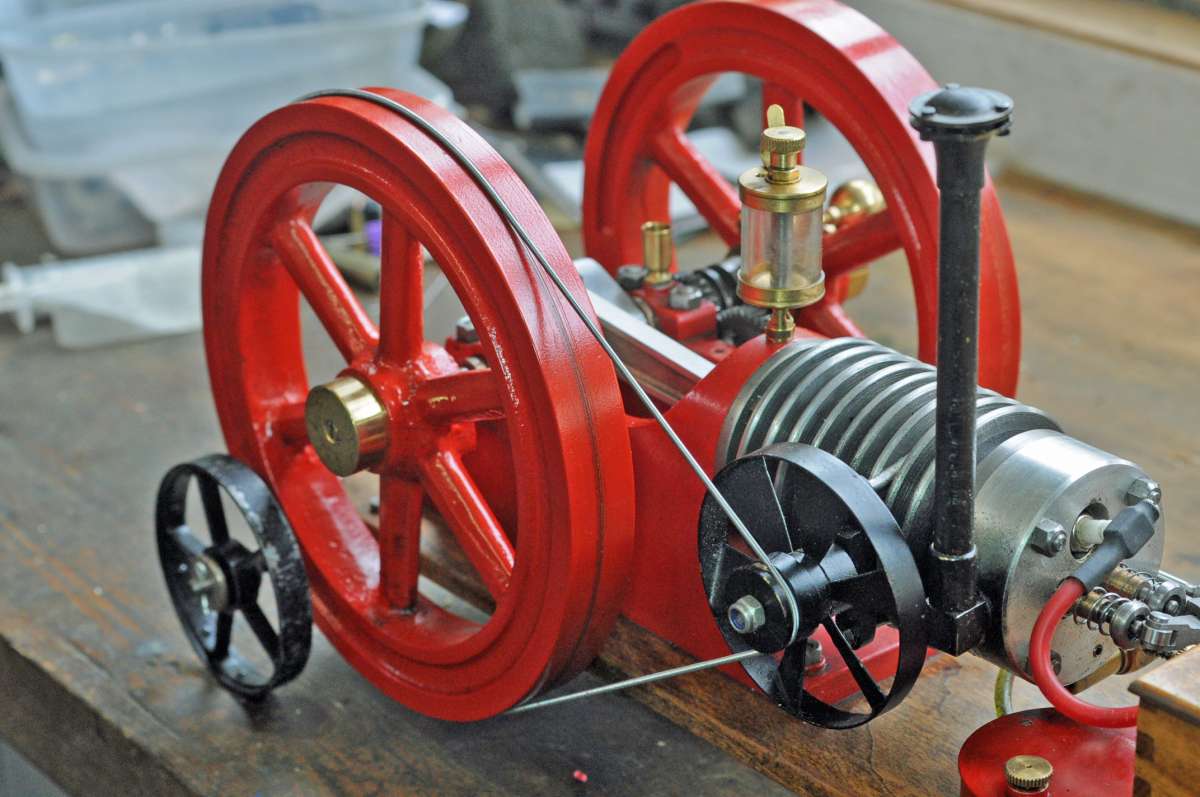

Finished rebuilding the Meddings drill I posted about the table repair a couple of weeks ago, photo at top is as bought but after table repair. Colour is quite a bit brighter than expected, probably through ordering from a tiny colour card swatch, grows on you. Very enjoyable job all round, had never dismantled a drill chuck before and after watching a sensible youtube video it turned out to be easy and worthwhile. Just got to tidy up and wipe the spray dust off everything and it’s back to the loco. But there is now a little Kennedy saw waiting in the wings….

Finished rebuilding the Meddings drill I posted about the table repair a couple of weeks ago, photo at top is as bought but after table repair. Colour is quite a bit brighter than expected, probably through ordering from a tiny colour card swatch, grows on you. Very enjoyable job all round, had never dismantled a drill chuck before and after watching a sensible youtube video it turned out to be easy and worthwhile. Just got to tidy up and wipe the spray dust off everything and it’s back to the loco. But there is now a little Kennedy saw waiting in the wings….