Wot I Did Today…

Not enough! I have these phases, rather worryingly.

More pondering than cutting.

Still, emboldened by the replies on the Manual Machine-tools section to my seeking advice on taper-turning attachments, I explored my Myford ML7 a little further.

Mulling over the many suggestions on how to use the compound-slide at angles far beyond its standard, very limited rotation, I soon designed a variation on a fitting first proposed by a Mr. Beecraft in the 1950s, I think. (See that thread.)

Essentially the compound-slide’s clamp bolt slots overhang the flanks of the cross-slide when it is rotated, so he made two extension flanks, simple steel bars, clamped to the cross-slide by long screws along the Tee-slots. These bars each have a central tapped hole for the clamp-screw.

I realised it is feasible to screw these to the slide itself, using the milling-machine to ensure alignment, perpendicular holes, etc: Mr. Beecraft may well not have had such luxuries.

I may though make them initially to the Beecraft design, to see how they perform, before risking drilling and tapping the lathe slide itself. They are only short, 5/8″ square bars with appropriate holes.

Using the compound slide at extreme angles, even at 90º or beyond, necessitates removing the cross-slide screw assembly; but apart from needing do that to use a taper-turning attachment, it would also allow shallow-angle facing such as Vee-pulley flanks and conical caps.

……

Another thread on this site talks about Myford oiling and gear-boxes.

I tried for the first time the fancy plastic pump-type oiler I had bought from the Myford stand at the Midlands show. I am not convinced – still ended up with oil all over the saddle rather than down the hole with its sprung ball. I think the ball must simply close the oil-can spout itself.

‘

Also pondered if I may be better restoring the machine to original. When I fitted a second-hand, early-type screw-cutting gearbox I bought a length of lead-screw material from HPC Gears to make the necessary short screw, preserving the original as “insurance”. (Later gear-boxes use the full-length screw.)

Yes, swapping change-wheels is a faff, especially having seriously obstructed access with 3cwt of unwieldy engraving-machine still to be recommissioned. However, for the sake of a few minutes’ extra work each time, it would give me the full range of both Imperial and Metric threads given by the standard banjo and wheel set. Metric pitches are not available with the early gear-box.

On the other hand, small threads (below M8 perhaps) are within tailstock die-holder range – or would be if the tailstock actually grips the holder – and I can screw-cut bigger metric threads on the Harrison, whose set includes a 127T wheel.

Besides, I have an all-metric “micro-lathe” still to be set up somewhere, ideal for making items like studs!

Oddly, investigating by spreadsheet showed my dear little EW lathe will cut ordinary ISO-M threads to fair accuracy over short distances (say, 10 turns) with its 8TPI leadscrew and two-stage, 5s-increment change-wheels! Its only problem is badly-worn headstock journals.

Dalboy.

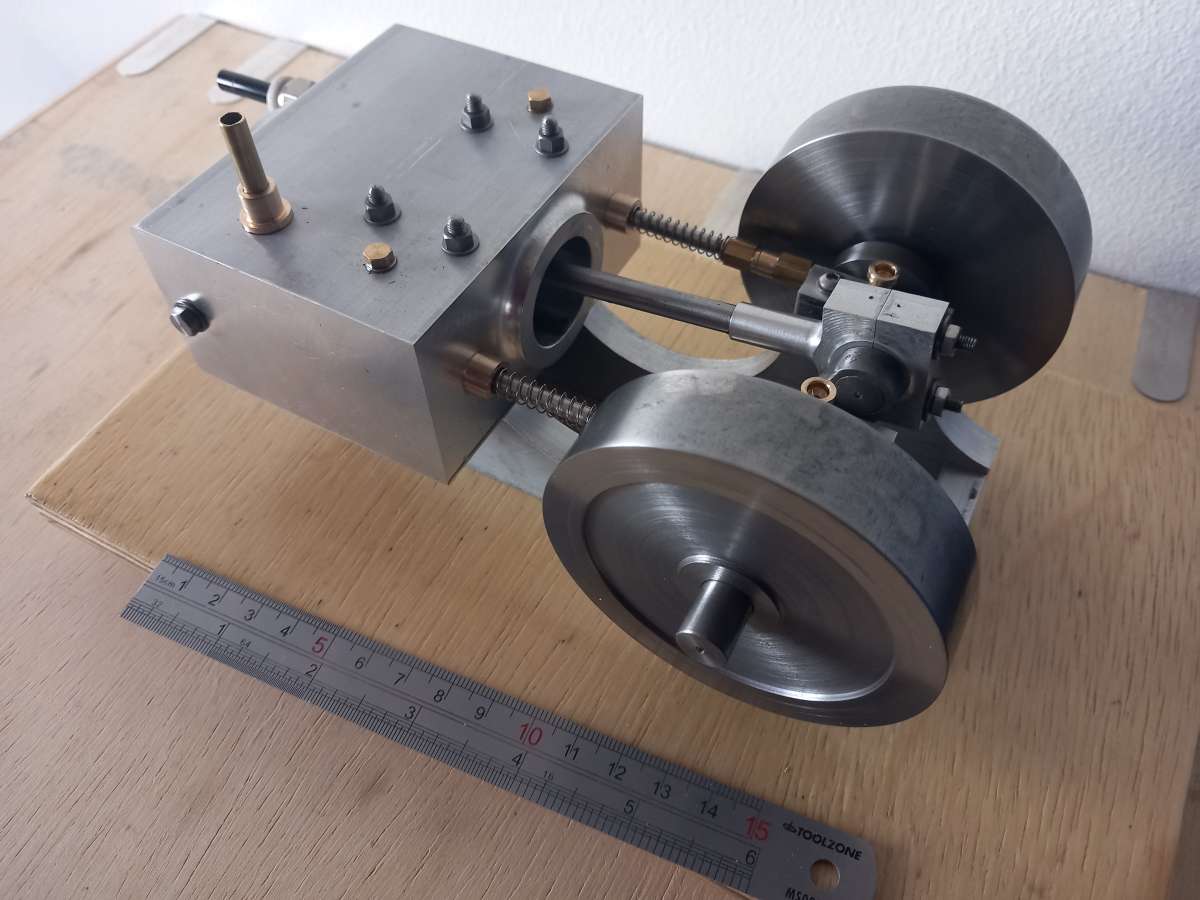

The adjuster screws are standard Metric fine M8x1,0. There’s a 45° included guide taper to help locate the valve stem – I made the little silver steel D-bit you can see at bottom right to open up part of the 7/32″ valve stem hole for this. It took 4 setups to do these parts, which made it quite time-consuming on the WM250V with milling slide.

The adjuster screws are standard Metric fine M8x1,0. There’s a 45° included guide taper to help locate the valve stem – I made the little silver steel D-bit you can see at bottom right to open up part of the 7/32″ valve stem hole for this. It took 4 setups to do these parts, which made it quite time-consuming on the WM250V with milling slide.