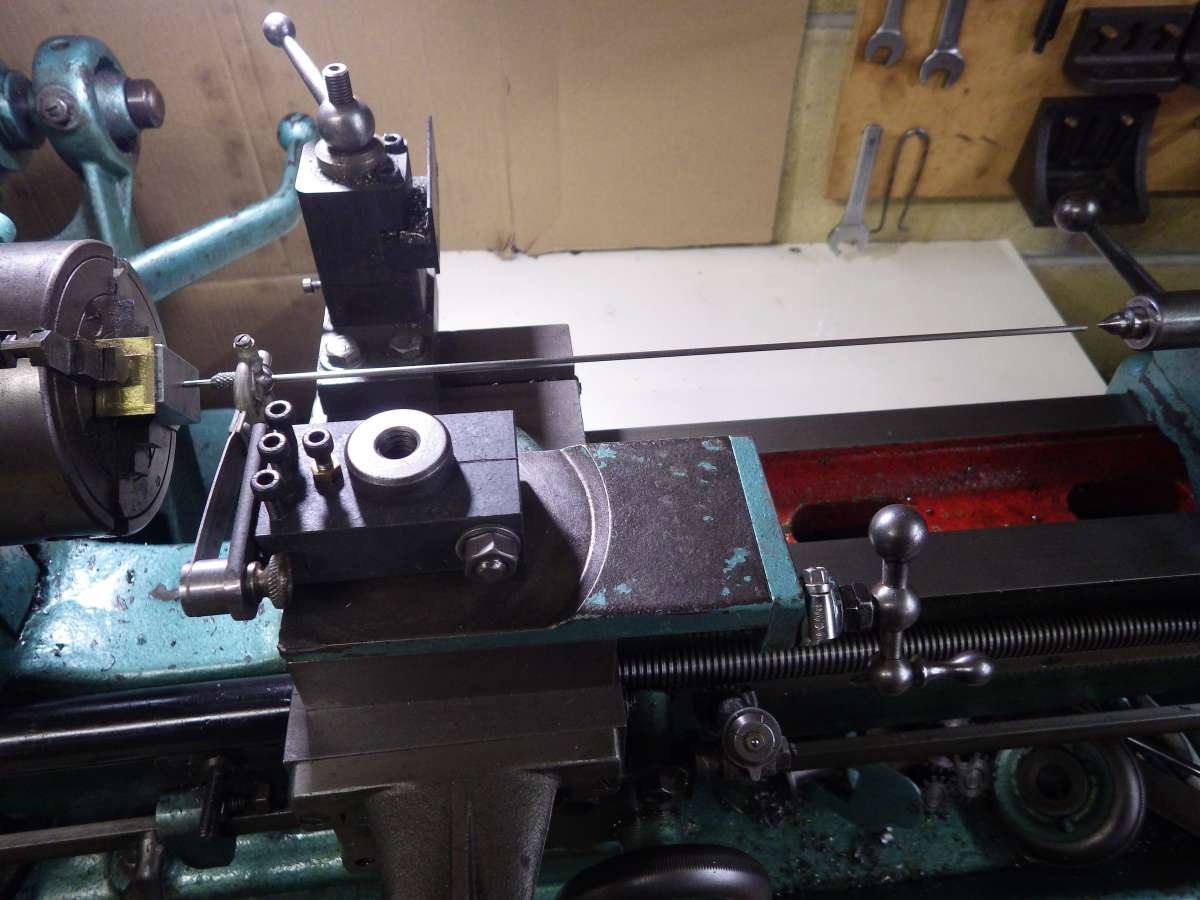

Had a little fight with welding pull. I am busy making a backplate to mount the Ball Turning boring head on. Got two 20mm thick plates and mill & joined them square together like an angle plate with the top side looking like a U shape engaging the QCTP on both sides instead of the usual one, so double clamped and can go up or down and locked in place. I plan on using this backplate for more things.

Decided to weld them together instead of bolts then grind and mill to have a seamless joint. I mill a V-groove on top joint, as they were clamped over an angle block. Start welding and ..boom…, it break two small cast clamps, quickly replace with larger ones clamped back to angle plate. After welded and cooled down it had pulled up somewhat with clamps released, like 2.5mm over 100mm, not good, the mistake I made was not to tack the inside, but that would caused a problem clamping it to the angle plate.

So today I tried to correct the problem, I milled a groove on the inside(Opposite) and weld that as hard as I could. After finished and warm it did not move at all.

Went to town, and a few hours later when cold, I could not believe it pulled back to square, so now some grinding and very little milling to reface it. This was a relief and surprise, don’t know how much stress is locked up inside however.

Dalboy.