My Engineers ToolRoom BL12 – 24 is a lookalike of the Chester Craftsman (and the late Warco BH600 )

In the 16 years of ownership, have never needed to remove the gap. But have never had any concerns about rigidity when taking cuts of upto 0.150" deep, or with smaller intermittent cuts. The motor is a 1.5 hp, 3 phase , powered by a VFD.

The Craftsman is a heavy machine, weighing 390 Kg,

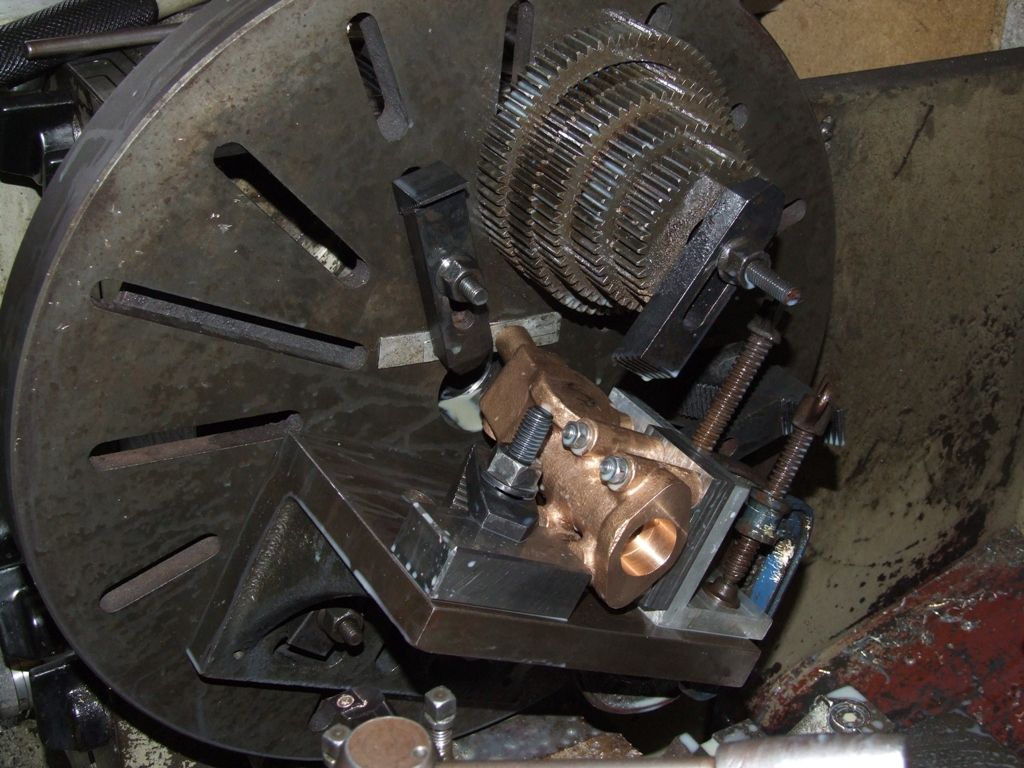

I have used it with a Vertical Slide, to flycut the ends of 3" x 1" steel bar, without problems.

When I had a Myford ML7, I did need to use the gap facility of from time to time, but found it not to be quite rigid enough for my needs, especially when using a Rodney milling attachment.

The BL12-24 bolts down using six 1/2" or 12mm fixings, where the ML7 uses four 5/16 or 8mm.

My lathe actually sits on six 1/2 UNF setscrews, with a nut above and below each lathe foot, which are secured to angle irons resting on the beams of ex warehouse staging, rather than the cabinet which comes with the lathe.

The ML7 was bolted to the steel bench.

Hence, I consider it to be much more rigid than the ML7.

In this case there should be no concerns over the bed flexing.

The gap is a useful feature, should you ever need to swing anything larger than 12", or 300mm.

Someone checked his BH600 before and after, having removed and refitted the gap piece. No misalignment was reported in the "refitted" condition, so the alignment seems to give no problems.

The Craftsman should be a versatile machine, given the Norton gearbox and PCF..

Howard

not done it yet.