Posted by Steviegtr on 10/03/2020 19:05:41:

… The finish is rubbish. … Not sure if I set it right.

The tool tilts down to the left. At the tip point, is this the centre of my work or not. …

Good to eliminate problems one at a time!

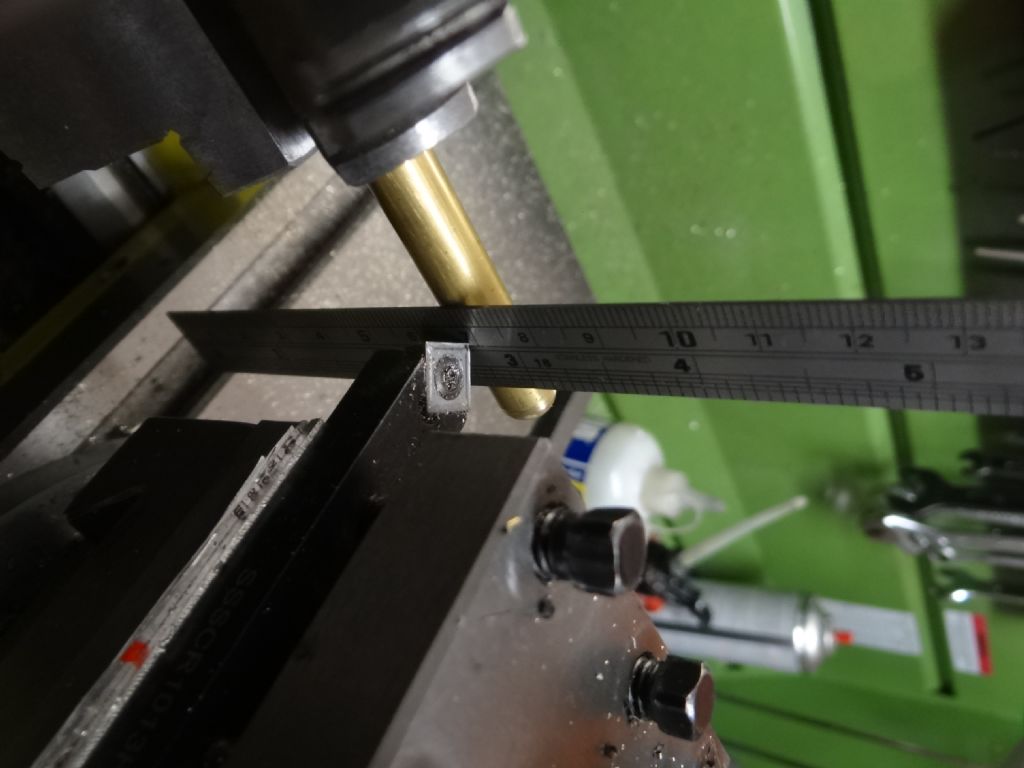

I set the tool height using either a length of rod faced carefully to centre height as a gauge or the steel strip method as per photo. Sorry it's sideways!

The steel strip is pinched between the tool tip and a rod. If the tool is too high, the top of the strip moves away from the operator. If too low, it tilts towards the operator. The tool is centred correctly when the strip is vertical.

When facing, adjust tool height until there's no pip, or deliberately make one so the point can be compared with a centre in the tailstock:

If still not cutting reasonably with the centre-height correct, it might be the material: ordinary mild-steel isn't wonderful. En1a-Pb machines much better.

Other possibles, 850 rpm is too slow, the bar tends to chatter because it's on the slim side, and/or a sharper insert is needed.

I think I mentioned in another post that running before one can walk isn't the best way for a beginner to start! In this case, boring an internal taper is harder than boring parallel. Once boring parallel is mastered, it's easier to spot what might be going wrong with a taper. And one shouldn't be boring until plain turning is mastered. When still at the unsure about tool-height stage, keep it simple. Only move to trickier jobs once reasonable results are achieved with the basics.

Dave

Edited By SillyOldDuffer on 10/03/2020 20:38:28

Tim Stevens.

. I would use the biggest boring bar that would fit the hole. You can probably get a larger diameter bar to fit your lathe. Measure the height of your bar above the bottom of the toolpost , it may be possible to get a 16mm one if the 12mm one has 4mm of packing shims under it.

. I would use the biggest boring bar that would fit the hole. You can probably get a larger diameter bar to fit your lathe. Measure the height of your bar above the bottom of the toolpost , it may be possible to get a 16mm one if the 12mm one has 4mm of packing shims under it.