Although not explicitly stated in the original post, this is for the gauge glass on a model boiler, so it is hot, potentially 160C+. I think this rules out Martin's link, which quotes a max temp of 80C. Otherwise that seems very similar to the one I linked in the original post. I think it also rules out plastic floats. The glass is 6mm OD, 3.8mm ID, so SOD's idea of sonar would need to be very small and tolerant of heat. It's for a test boiler, so demand can vary from nothing to max, and it might not be driving an engine, or the engine might not have a built in pump, so John's fixed pump displacement won't hack it. It won't have a hot well, so that's a non starter

I've just spent a fruitless hour trying to find the slotted opto I know I've got. I've obviously put it somewhere safe. I'll have to wait until my opto transistors arrive.

As to why not just copy the original, well I wouldn't learn much doing that, and even at my advanced years that is a big part of why I set about things.

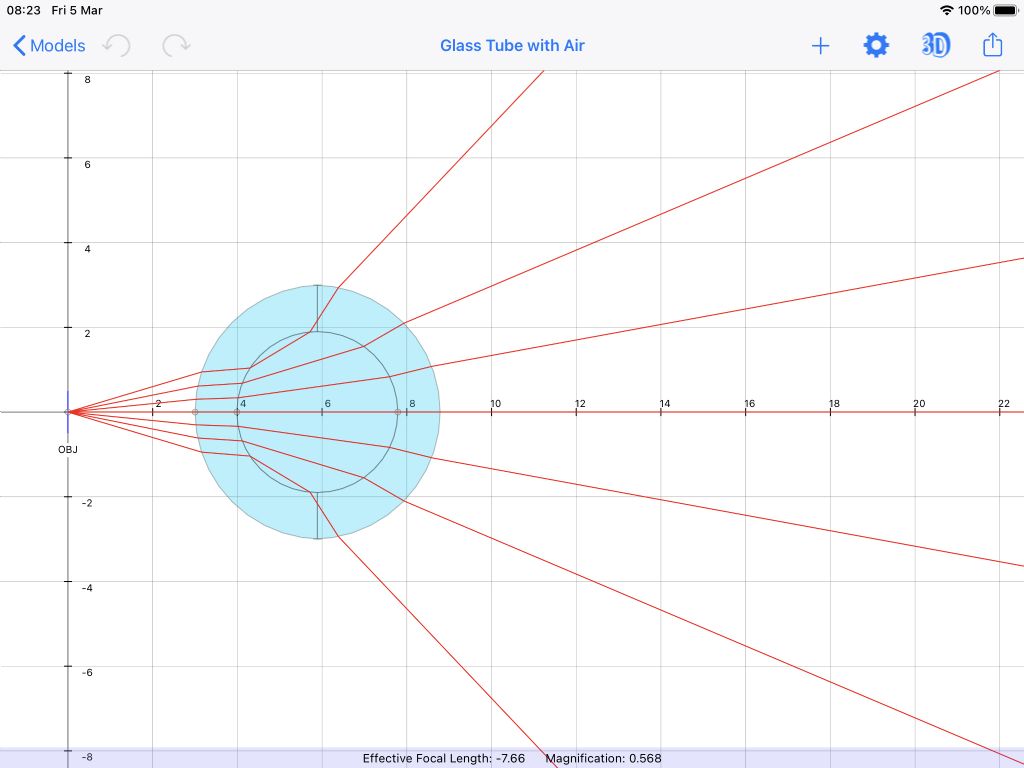

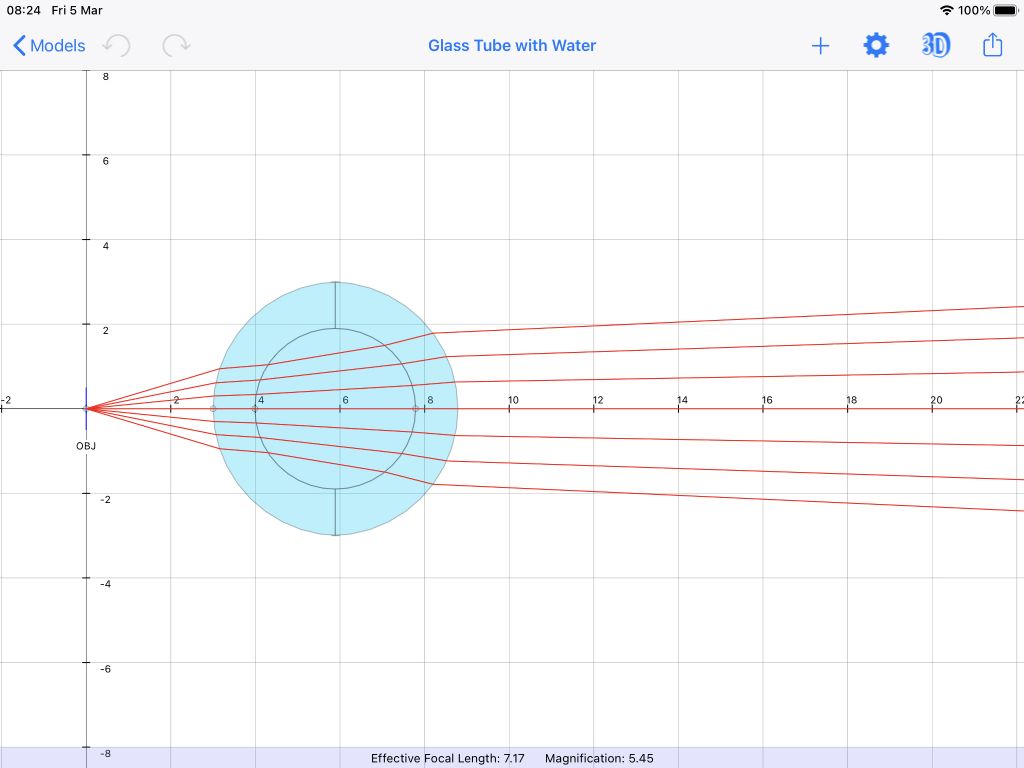

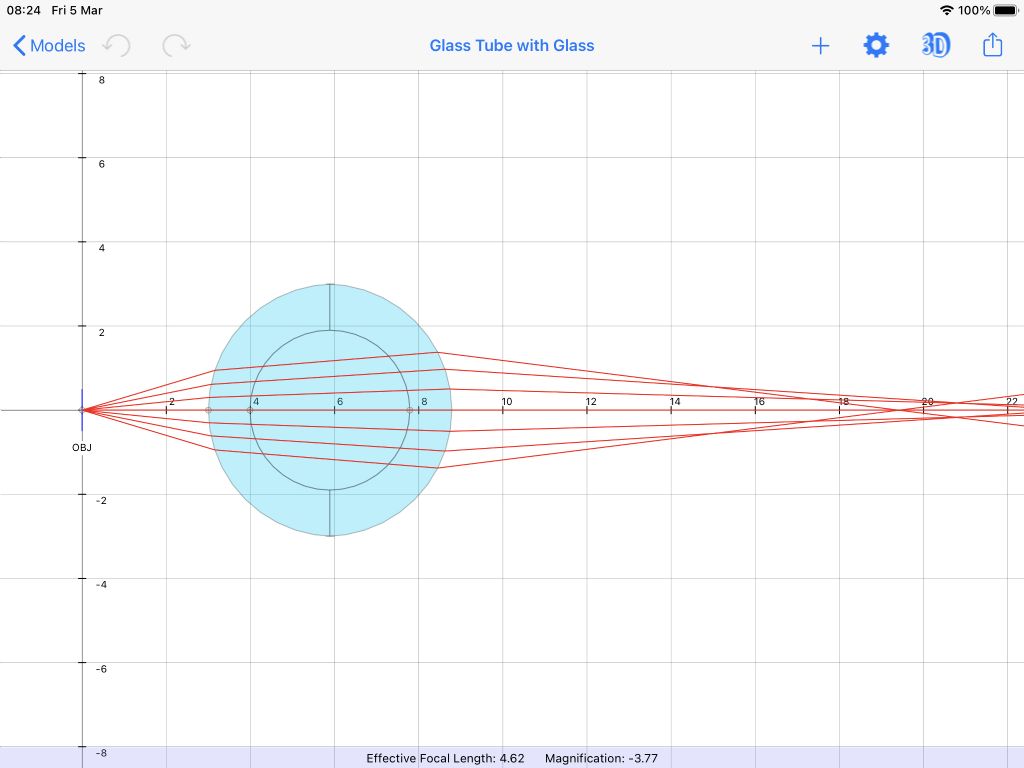

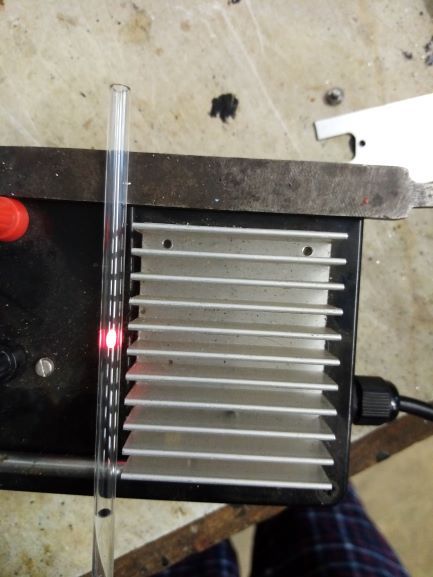

I'm beginning to think that Michael's idea of cylindrical lens might be the answer, if the water makes it splay out like a fan it would cause a step change in intensity, same amount of light in a wider beam. I'm going to rig up an LED facing a tube and have a play, but tomorrow, tired out by birthday festivities.

I quite like Noel's capacitance idea, but it's beyond my electronic expertise. Are we talking relaxation oscillator and phase locked loop chip? If so I've just bought some of those for another project, but I can't find them either!

Edited By duncan webster on 04/03/2021 22:02:46

Edited By duncan webster on 04/03/2021 22:03:34

duncan webster 1.