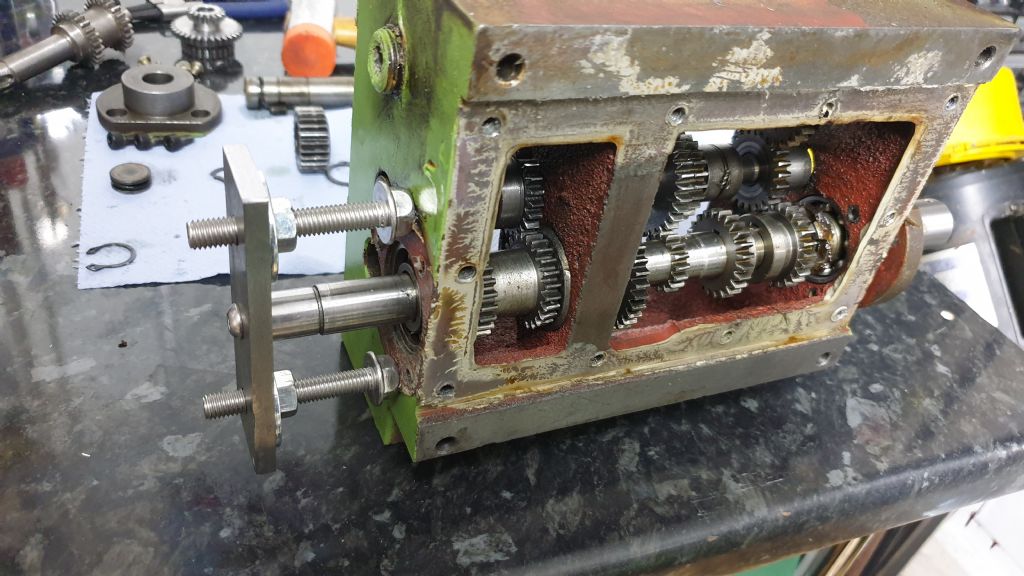

Warco WM280V-F Gearbox

Warco WM280V-F Gearbox

- This topic has 65 replies, 17 voices, and was last updated 8 December 2020 at 22:06 by

Noel Carlyle 1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Generator size for vfd controlled 3 phase 5.5 kw motor

- Marlco knurler wheels

- Blue crystals. Probably not meth?

- DIY Pendulum Timer – GPS-Synced Beat Analyser

- Beginner with newly bought lathe – many questions

- Tangential tooling

- Hello from Kent

- Clarke CL500M longitudinal feed screw

- More Lidl questions

- Lubrication of headstock bearings on a Clarke CL500M