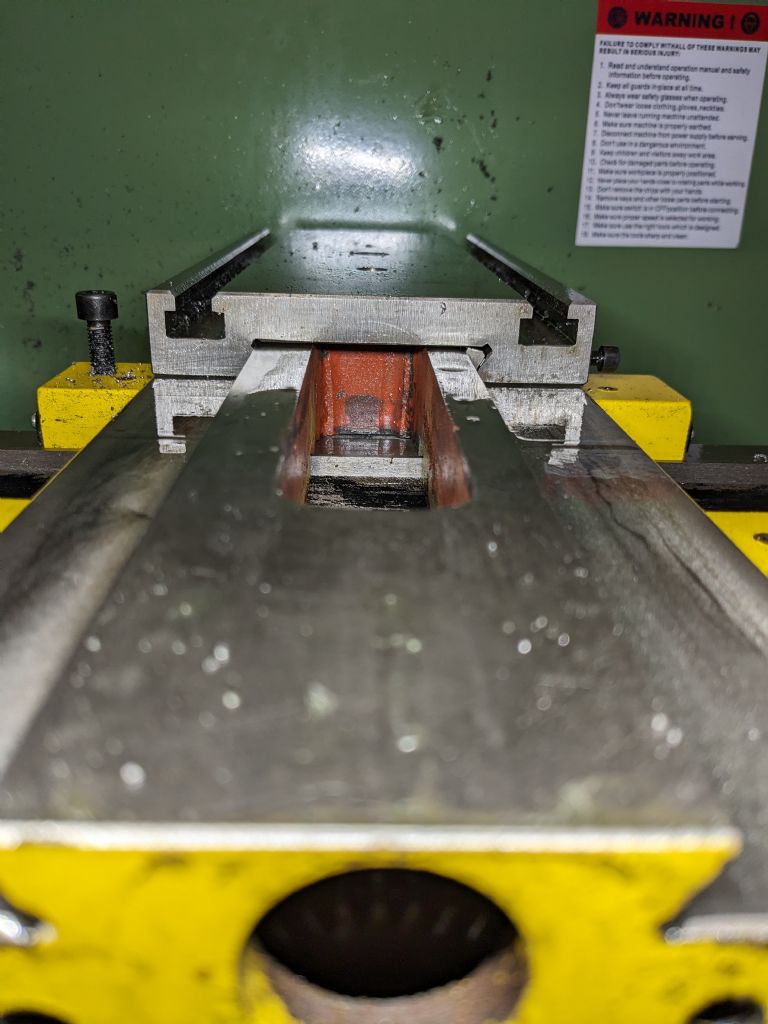

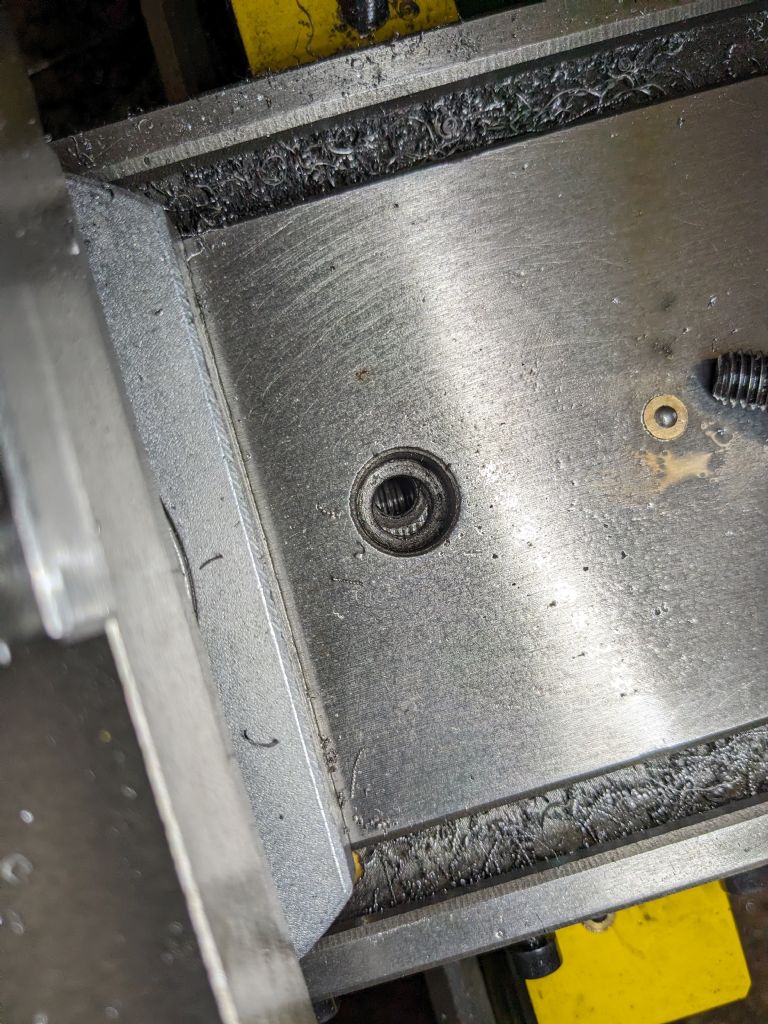

I wonder if your nut broke because the crossfeed screw's driven by a roll pin through the pinion?

My WM250V had a brass shearpin, not a roll pin in that position. Presumably the theory was that the pin would break if the crossslide met heavy resistance under power feed.

What actually happened in my case was that the brass pin broke when I engaged crossfeed by mistake and caused a severe collision (IIRC I was working late at night on summat), and one of the bits left in the crossfeed pinion fell out into the apron gearbox, jamming it perfectly. I had to take it off to find out what had happened, and clear it.

I made a new brass shearpin with a light tap-fit, to reduce the chances of bits falling out next time – and have had no trouble since.

Reading what you found, plus the chance I had of examining the Chester equivalent lathe at my son's workplace, has led me to think that there's some variation in final assembly of these machine – possibly different factories and very likely different individuals with their own procedures. For example – the Chester had a brass shearpin driving the longitudinal leadscrew, whereas my Warco had what looked like silver steel, and now you've found a roll pin in the crossfeed drive.

Whether you put back the rollpin or replace it with brass probably depends on which sort of jam you're more scared of…

Edited By Mick B1 on 27/07/2023 10:01:03

John McCulla.