~~I have almost completed the installation of the economy WARCO DRO scales on my WM16 mill and would like to point out that not all jobs like this are as simple as one might think.

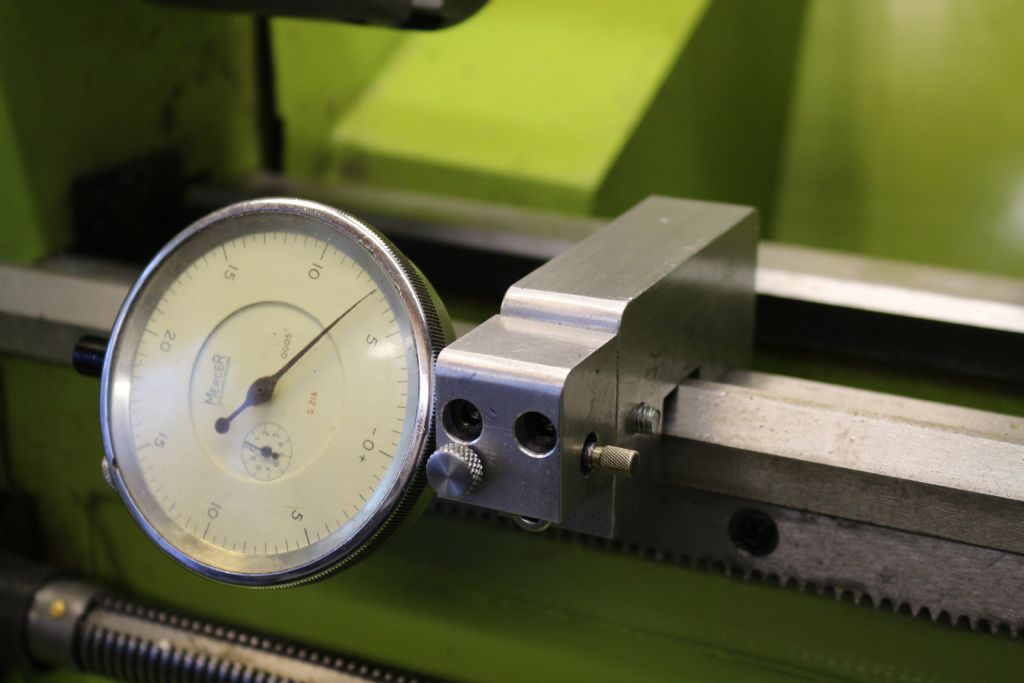

First and (I wasn't thinking) it did not occur to me that the scale bars need to be parallel to the top of the table to get the best accuracy. OK, it seems obvious now but Michael the fitter at WARCO made the penny drop for me. Using a clock from the table sorted that problem out and the X scale was fitted without to much trouble.

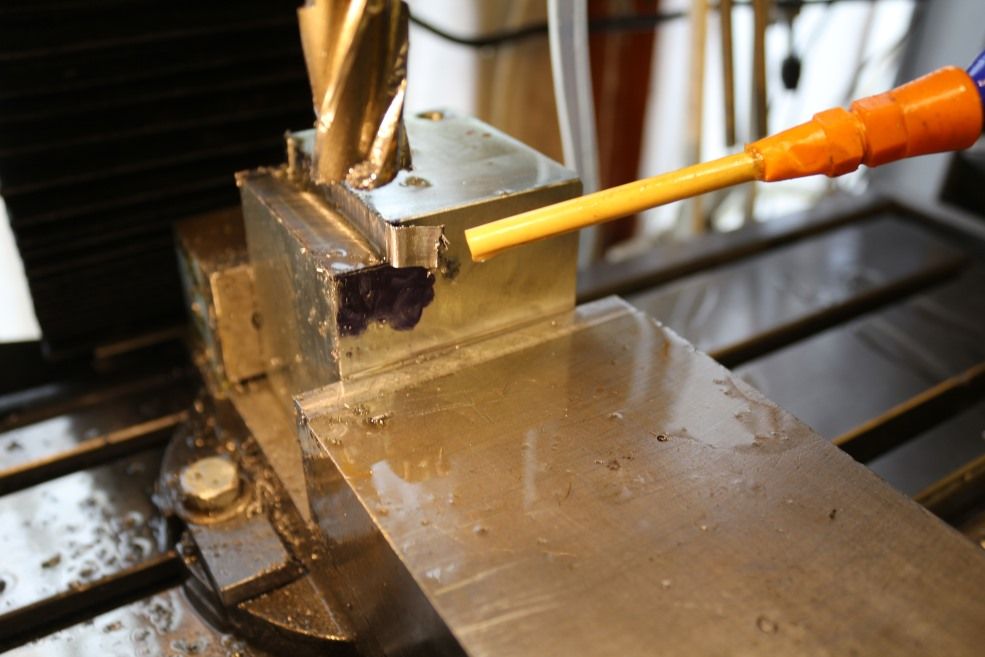

Y scale was a b**tard. First thing identified was that the scale was about 6mm to long. Had read that this can be got round by hack sawing to length. OK, so here goes with a new ,expensive German bi-metal blade I went for it. Half way through the very tough scale it decided to work harden itself and I had to resort to an ALDI version of a dremmel fitted with an elastic wheel to finish the cut.

Next, marked out the holes for the scale on the machine casting for the 6mm fixing screws and using a 3mm pilot drill attacked the casting. Zilch……..all I did was remove the paint! The casting, front and rear was as diamond —– "chilled" is not sufficient to describe how hard it was. An hour or so later using the ALDI dremmel thing loaded with a 3mm diamond burr I managed to plunge in to approx 4mm deep and this was enough to allow the tapping drill to get a bite and find the soft stuff – phew!

Fitted the scale and found the supplied bracket for the readout sensor was unusable. Spent the next two hours making and offering up an ally fixing bracket to replace it. Finally got it right and it was time to drill the third and final hole in the casting to fix it. Would you believe it? The bl**dy casting was chilled again! More diamond grinding and eventually drilled and tapped for the fixing screw.

Last job was to fix the XY remote display to the top of the 'lecrix box and connect the USB cables to the scale sensors.

Hefty slap to the forehead as I realised that the USB plug in the X reader was going to foul on the base casting and damage either the cable or the reader.

In order to overcome this prob I will have to use a 90 degree USB thingy which I have just ordered from a UK Ebay website only to be informed that it will take up to 10 days to be delivered from somewhere in the Orient.

Having been retired now for two years I had hoped that "stress" would be something that yuppies suffered from – looks like I was wrong.

Rik

Cabinet Enforcer.