Hi all

Mark P; – I have never found the need to consider bracing the column, I have put on a d.o.c. of 1mm (CI, MS, Ally' & Brass) without it complaining, from your post it seems that you are putting quite hefty cuts on it, I would be wary of stripping the intermediate plastic gear if too much is put on, unless you've already remedied that?

Rik,- as with Thors machine the height from my stand top to the underside of the table is 106mm (wouldn't guarantee that all casting batches measure the same), that is to the bottom of the dovetail slides.

Thor – from your album it looks like yours is the Amadeal version of the WM18 if it has the MT3 (no connection) as do the WM 18, BF20L, PC45, Grizzly G0704 & Optimum BF20, the only differences I can note is the layout of the electrics, switching & colour scheme, looking at the WM16 & Grizzly G0704 parts lists, they are identical, If anyone wants a comprehensive manual & parts list look up .. grizzlyG0704.com. .. the manual for my WM16 looks as though its pages are a Chinglish version extracted from Grizzly's manual.

As far as mods to my machines goes,- so far I have fitted DRO's to the X & Y axes on the mill ,altered the chip/splash guard & fitted a couple of stops to the head to maintain 'zero tramming', any angle work needed (very little so far) I have used my angle vice.

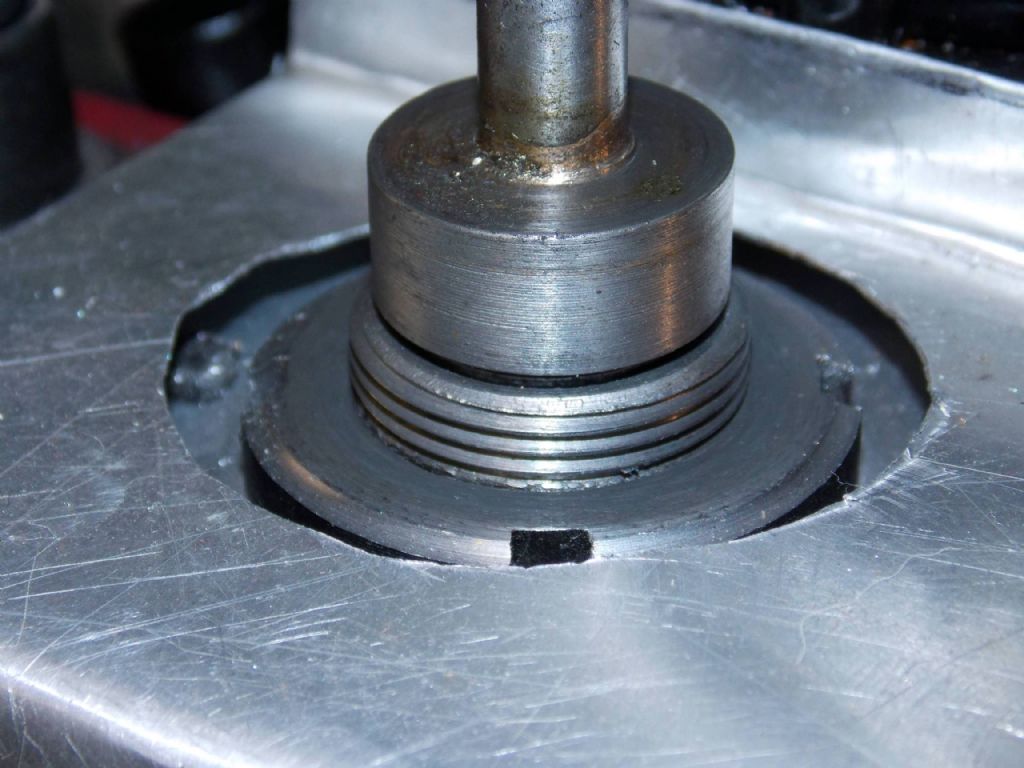

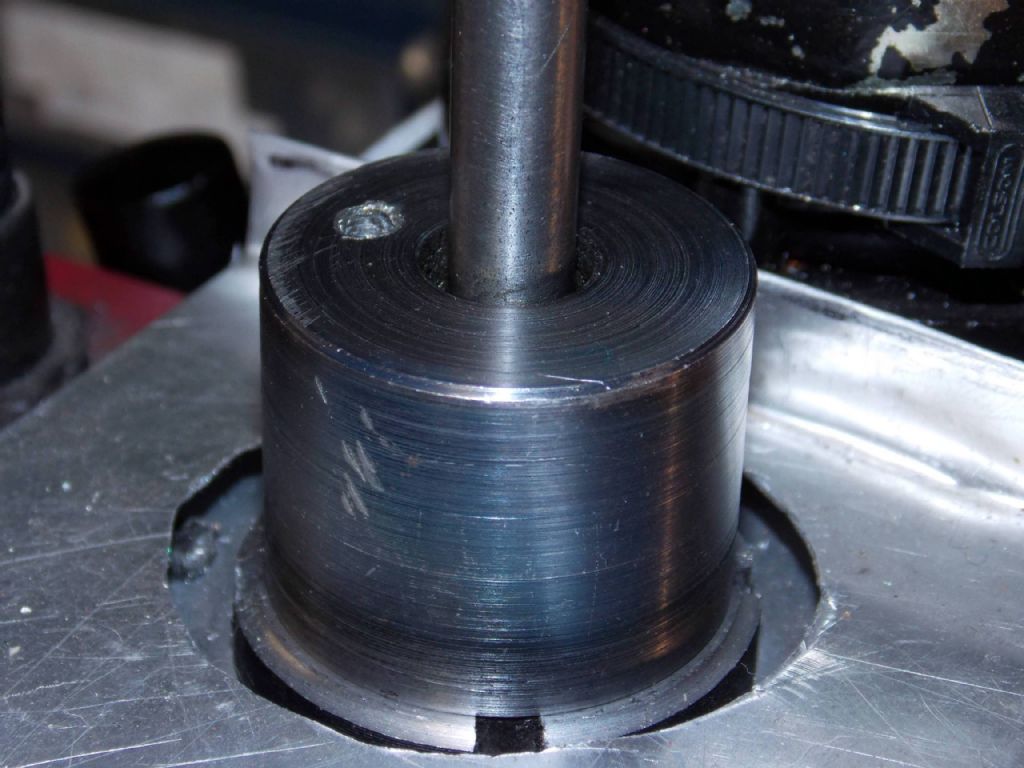

On my 250 V-F.. – I have modified the topslide to take a Dickson type toolpost '00' size, (simply as I had it plus 10 holders from previous), although I'm sure it will take the '0' version plus Warcos version (item 9009.250), from their blurb it seems that you have to ask them to machine these to fit the 250V-F (extra cost ?) I actually machined the boss off my topslide to accomodate the QCTP, if I need to use the original t/post then it would be to simply machine up a boss/collar to fit over the QCTP stud. I have modified the compound slide friction collar by adding a machined knurled collar for easier grip as the original set up was small difficult to get my (fat) thumb & finger in to grip..much improved. The chuck guard has been modified to allow me to see better, the original configuration had the frame edge blocking my view down onto the chuck (nitpicking)

I have a couple of ' to do it' items to get on with..

1. Replace the compound gib strip to brass, proper size, as the orig' is just an ms strip fitted & leaves a lot to be desired

2. Make up a saddle lock for more solid saddle locking when facing / parting off, the original is a allen screw locking system on the bottom right corner(I'm sure all of you are well aware of this).

3. Fit a coolant system to lathe / mill. I have a temp system I use for both at the mo'

All mods can be be seen in my album pics; if anyone has already done similar 'to do it' mods would appreciate pics /drawings. Am in the process of updating my album so if you can't see any pics mentioned let me know.

Cheers for now

George

Edited By mechman48 on 16/05/2013 14:50:03

Cabinet Enforcer.