Posted by Michael Gilligan on 22/02/2019 09:30:27:

Posted by SillyOldDuffer on 22/02/2019 09:15:26:

As Bazyle points out, the numbers are almost certainly back calculations

.

…

It is surely not unreasonable to think that direct angular measurements may have been taken.

MichaelG.

Maybe – so much depends on what the individual knows and his instruments!

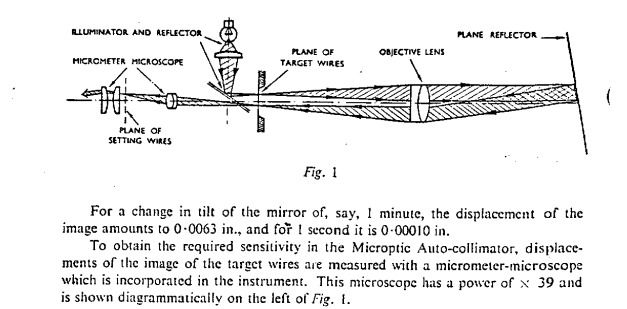

I guessed 0.012mm to be a calculation because the very best I could measure is about ±0.01mm, 0.002mm is a step too far for me. (0.00007874016 inches is less than the famous tenth many aspire to and never achieve.) Likewise 5 minutes of angle is only 0.08333°, which I would be hard put to measure directly. So I conjecture both numbers come from an opposite over adjacent calculation based on DRO & DTI numbers.

I have a precision bubble that could easily detect a 5 minute slope, but it's not calibrated. Though I wouldn't do it that way, I understand how a bubble could be used to check a mill was trammed correctly but not how to measure the actual angles between table and head.

Even measuring distance, I recall there's a problem calculating with trigonometry in that the tangents of small angles are all close to zero, making the sums iffy as well.

tan(0.005) = 0.000087266

tan(0.01) = 0.000174533

tan(0.02) = 0.000349066

How would you take an accurate angular measurement in a workshop? Something like a baby theodolite perhaps? I love this forum, the more I learn the more I find I don't know, or have misunderstood!

Ta,

Dave

Edited By SillyOldDuffer on 22/02/2019 13:47:29

Dave Halford.

Dave Halford.