Hi,

I have a Warco MiniMill. I will tell you what I know, my experiences and then leave the decision to you. I cannot comment on the Sieg Super X2.

The MiniMill is not made by Sieg, although it does use the same basic idea and layout. It does use the same internal gears (see later). My MiniMill was made by Yangzhu Real Bull Machine Tool Co. Ltd. The impression I get is that there are a number of Chinese factories making machine tools to the same basic designs, but with small differences.

About my mill.

Some of the slides were/are in a very poor state and require work on them to improve them. David White has produced a number of articles in MEW on improving the Sieg X0 which seem equally applicable to the X2 and equivalent. He has also produced an article on the Weiss WMD25LV machine in which there is a photograph of the internal gears. This photo looks to be identical to the MiniMill. White also says that he found lots of casting sand etc on the Weiss. So did I on the MiniMill.

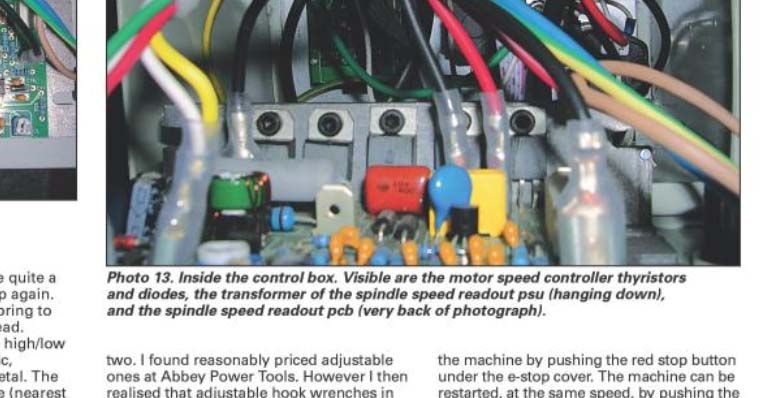

The Sieg X2 (350watt motor) is well known for two problems. These are the breakage of the plastic internal gears, and the failure of the electronic control board. I have experienced the gear failure on the MiniMill, but not (yet) any electronic failure, however, the fact that there is a more powerful motor may indicate that the electronics have been uprated and thus eliminated the problem. At least that is what I hope.

In respect of the internal gears, these can be difficult to change, however, Arc Euro Trade do a set of metal gears, supposedly for the Sieg C3 lathe (I think), but advertised by them as suitable for the X2 machine, and I can confirm that they will fit the MiniMill.

Another option to overcome gear breakages is to convert to belt drive. There are kits available which may or may not fit the MiniMill. Claimed advantages are that a higher speed may be obtained and the machine is quieter.

On my machine, I could not get the fine vertical movement to work. The handbook didn’t mention it, and did not even have the correct information about switching on. Fortunately, I found a downloadable manual produced by LittleMachineShop.com which explained about the fine vertical movement. I discovered that the fine feed mechanism was binding to such an extent that it was unusable. Careful adjustment made it work.

The MiniMill uses a counterbalancing spring to take the weight of the head. On mine the spring has lost some of it’s tension, but that may be because of something I did.

I fond the dials difficult to understand. They are not calibrated in anything recognisable, so I made a conversion label which I have stuck to the machine. Also, the variable speed is not calibrated. Again I have made an approximate speed label using a cycle computer to measure the speeds.

I suggest you hunt around the forums for the X2. You will find a lot of information on improving the X2 series of mills (which will include the MiniMill) and on setting them up, eg vertical alignment both back to front, side to side, and the alignment of the travelling head. Also information on stiffening the vertical column. David White has a novel method of doing this as well.

The Warco MiniMill has a larger table than the Sieg X2.

I can’t think of anything else.

Good luck in your quest.

Peter G. Shaw

mark smith 20.