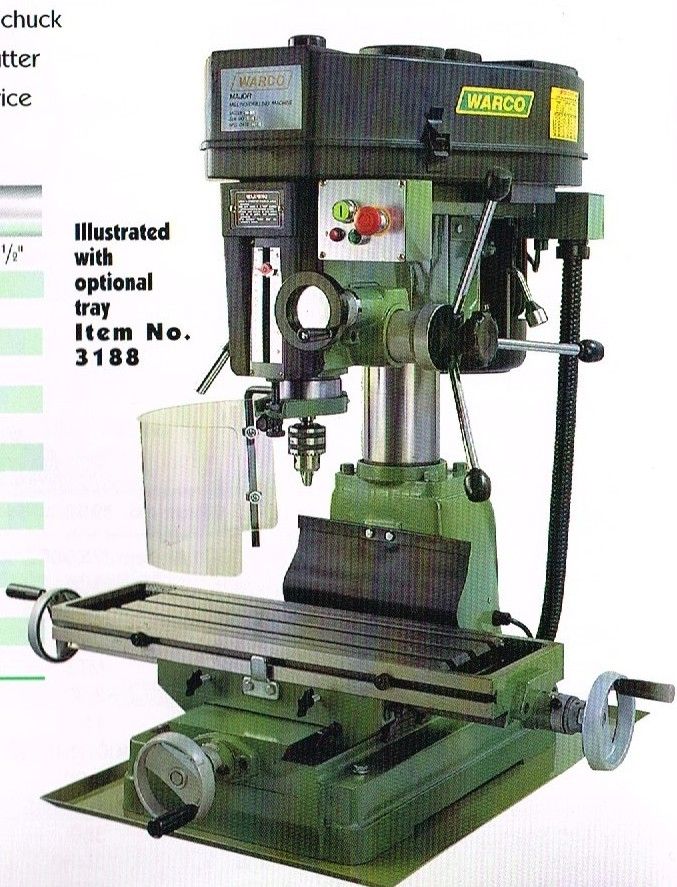

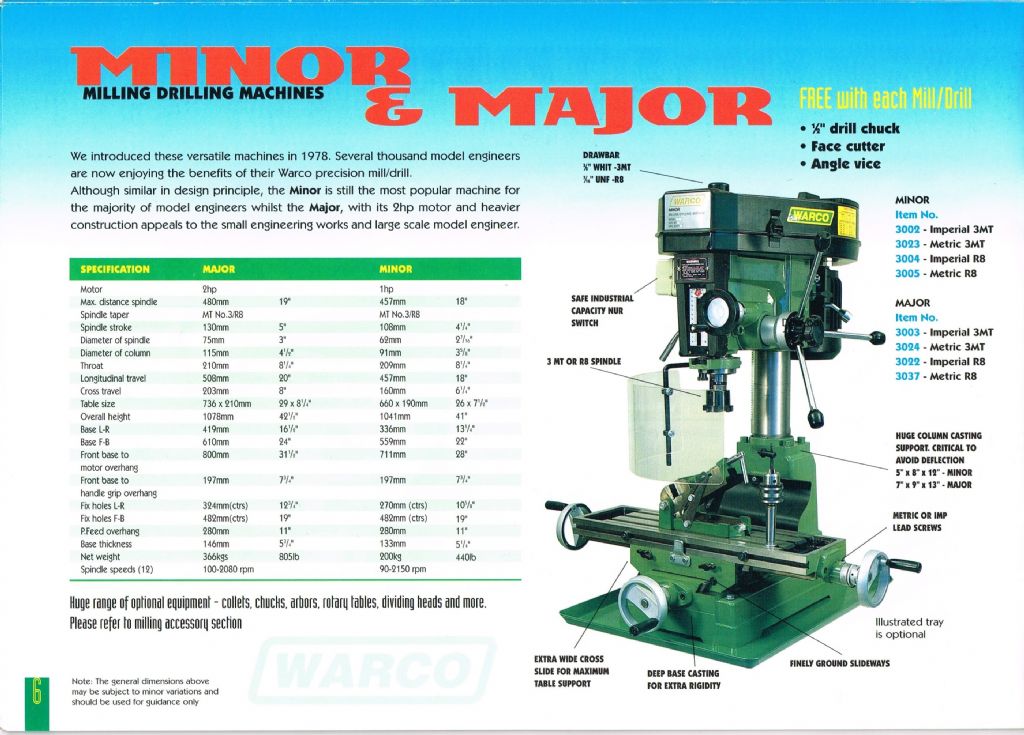

Not certain what an MD30B actually is, so a picture would help identify it for sure. My guess is it's the common round column mill like the one linked by Old Mart, or this current Warco model.

If so download the Grizzly Manual for their similar machine. Grizzly Manuals are usually more comprehensive than British ones.

I doubt there's a beginners guide to this particular machine, but don't worry, in this class they're all much this same! The controls differ in detail rather than function. You might invest in a copy of our very own Jason Ballamy's "Milling for Beginners",

I echo Dave Halford's concern that the machine really needs tramming? What's wrong with the way it cuts, and how is the error being measured? The concern is tramming is much easier to upset than improve.

However, assuming it's the same machine, and after doing what Grizzly say about installation and levelling and being sure it's worth fixing, read on.

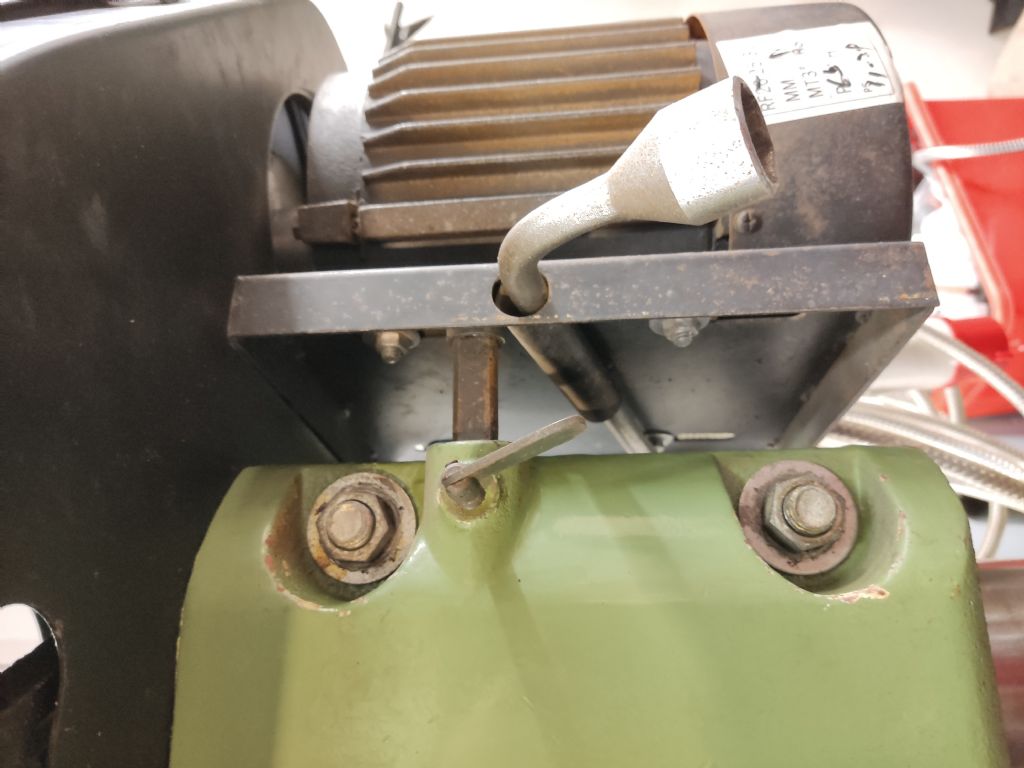

I believe the round column is fixed to the base with four vertical bolts or nuts on studding, one of which can be seen right-rear in the Warco picture above.

After the bolts are slackened, the column is lifted so that corrective shims can be inserted underneath. Easy in principle. Several owners have reported their problem was paint splashes under the column foot, in which case the the whole will have to be lifted off and both sides cleaned.

It's a heavy and clumsy job, and inserting the shims correctly is likely to be fiddly. As a weakling with a bad back I'd use an engine crane. Can anyone who has done it advise Paul please? My feeling is best to learn the ropes and read the book before attempting to tram a mill.

Dave

paul mcquaid.