Hi

I've got an A1-S, the version sold by Myford and have found it to be a good machine, I only bought it as a stop gap when I had to move and sold my Bridgeport, It takes the R8 tooling ,I still have it 8 years later so a obviously quite happy with it! The speed range as supplied is a bit odd with a few gaps in it, but this is easily cured with a 3 phase motor and inverter. Mine was metric and a cheap Chinese ( Sino) DRO has proved excellent.

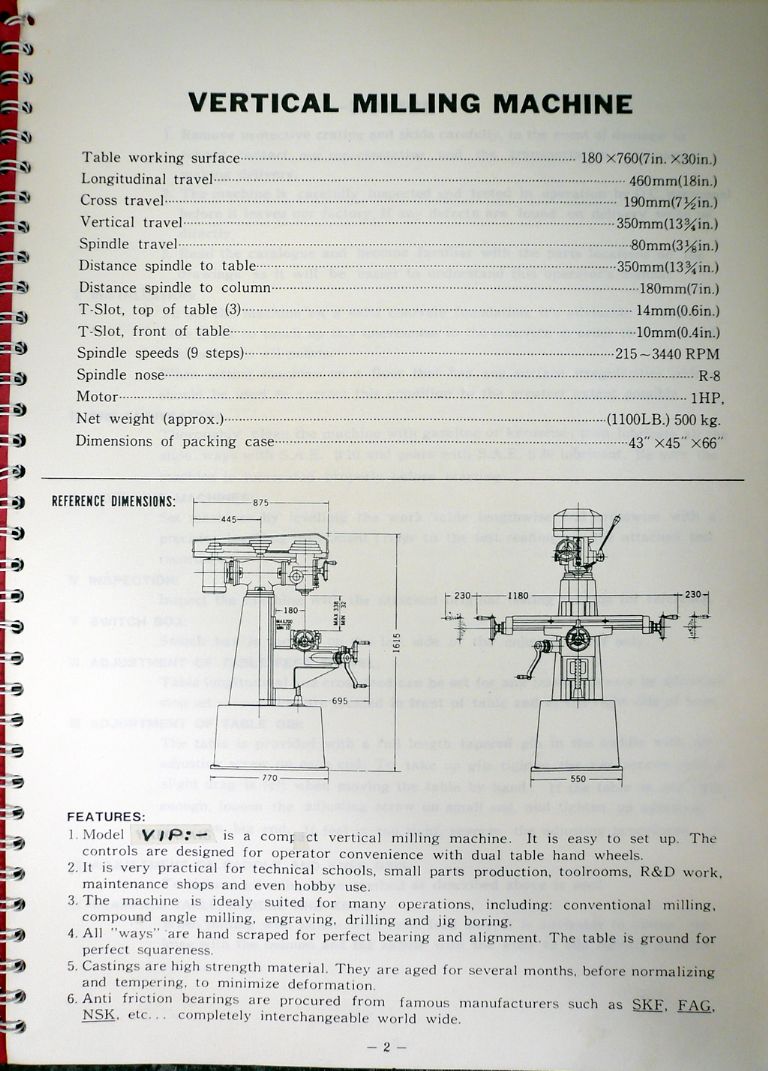

At one time I briefly worked for a company that imported and sold these under the RMT name, this was the very early 80's, I remember being quite impressed at the time and thinking they were a reasonable size for model engineering. I have seen the same machine badged as Elliott, Warco, Alpine, RMT, Myford, DST and I'm sure there are many more. The firm I worked for checked theirs very carefully and there were a few with alignment problems with the rotating base for the milling head, these were rectified by scraping true before despatch. I do believe these were made to the same basic design by different factories in Taiwan. The ones we got were made in the works that made Bridgeport copies under the Condor name and were of a very reasonable standard. The standard of pre delivery inspection would obviously have a bearing on which would the better choice, Denford being a major manufacturer would one hopes check machines thoroughly before despatch, the part about fitting quality bearings looks promising and would seem to cover both suppliers.

Provided the machine is in good condition I don't think you would be disappointed with its performance or capacity.

Hope this helps, you can always pm me if I can be of help.

Dave

Edited By Dave Wootton on 25/02/2022 14:05:35

Edited By Dave Wootton on 25/02/2022 14:06:54

SillyOldDuffer.