It might be worth just first checking the preload on the spindle bearings, although you confirm they are smooth and quiet. If the spindle is floating about a bit then this would show up on the outside diameter as well as the taper, a slight adjustment of the preload may eliminate the excessive run out you have.

I have once machined an INT 30 milling spindle taper in situe on the mill, with the head tilted over to the correct angle, using a boring tool secured in the milling vice. Only as a last resort, and it worked well.

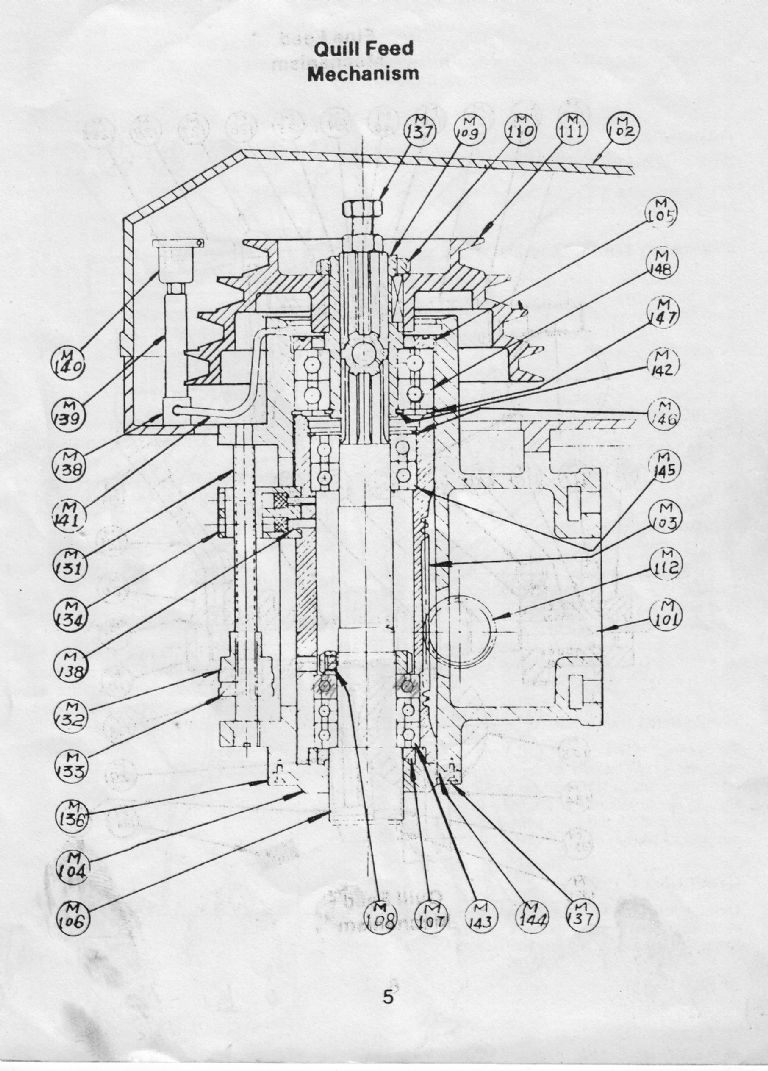

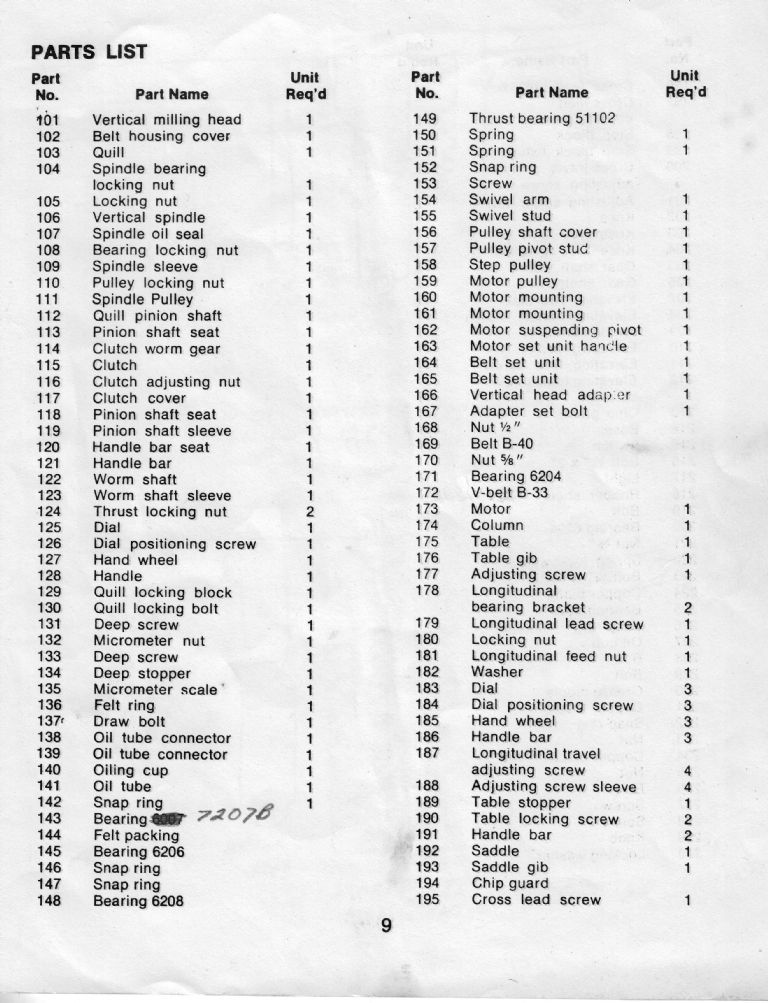

I can vaguely remember removing the quill and spindle assembly from my Warco VMC many years ago. I'm sure once the quill handwheel and pinion shaft and spring are removed, together with the depth stop, the quill will slide out the bottom of the head. The spindle has two castelated lock nuts for adjusting the preload, as far I can remember. If the gear rack teeth cut on the rear of the quill continue to the top edge of the quill then the pinion shaft may not have to be removed.

The very early Warco VMC mill that they offered in the 1980's was identical to the Taiwanese made Myford VMC, but in the 1990's the Warco VMC was no longer the same machine, using different castings and other detail differences, although overall it looks the same, and has similar dimensions and capacity. The Warco VMC I have was made in Taiwan in 1997 and is the version that has now been produced in China for some years.

Anyway, prompted by this thread, I have just been in my workshop to measure the run out on my Warco VMC R8 spindle. I get a reading of 0.0002" run out on the lower portion of the spindle taper, and no change further up the taper.

Although the Taiwanes made Myford VMC is generally made to a higher standard than my later differing Taiwanese made Warco VMC, I can recall a conversation I had while on a visit to the original Myford plant at Beeston in Nottingham, around the mid 1990's I think. While being shown some machines hidden away in some back rooms I spotted a new Warco VMC that they said they were examining, I think because the Myford VMC was being discontinued. They didn't really like the way the Warco VMC was made, but they did admit that they did have to put a stop to the Myford VMC manufacturer's method of "finishing" the spindle taper by inserting a piece of wood wrapped in sand paper.

Edited By Lathejack on 13/11/2022 23:31:07

Edited By Lathejack on 13/11/2022 23:37:27

Hopper.