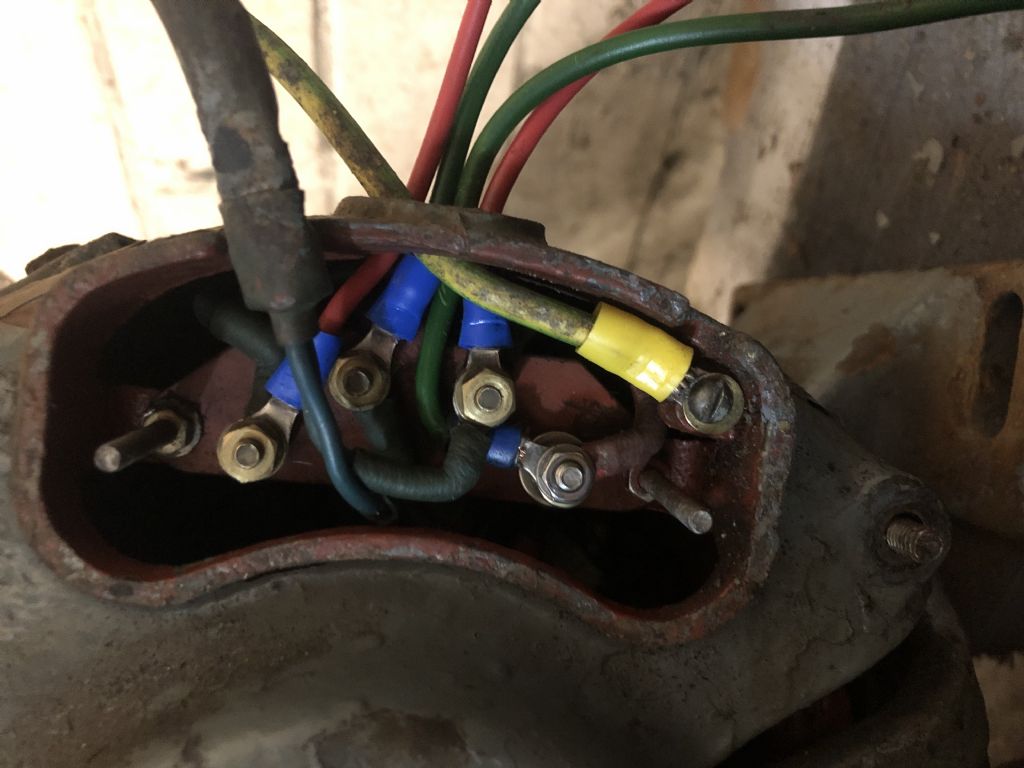

Are there any markings inside the terminal box or maybe pasted inside the lid? A, AE, AZ, Z, K, T, S or what?

There are at least 5 different types of single-phase motors each wired differently; they can have zero, one or two capacitors (sometimes in the same cylinder), and a centrifugal switch, or not! And sorting out reverse adds another layer of complexity. Quite a few combinations to try unless some clues are found, and some cause magic smoke.

At least one capacitor being visible means it's not a split-phase motor, but it could be:

- Capacitor Start, Capacitor Run (2 variants), or

- Capacitor Start, Induction Run (has centrifugal switch), or

- Capacitor Start and Run.

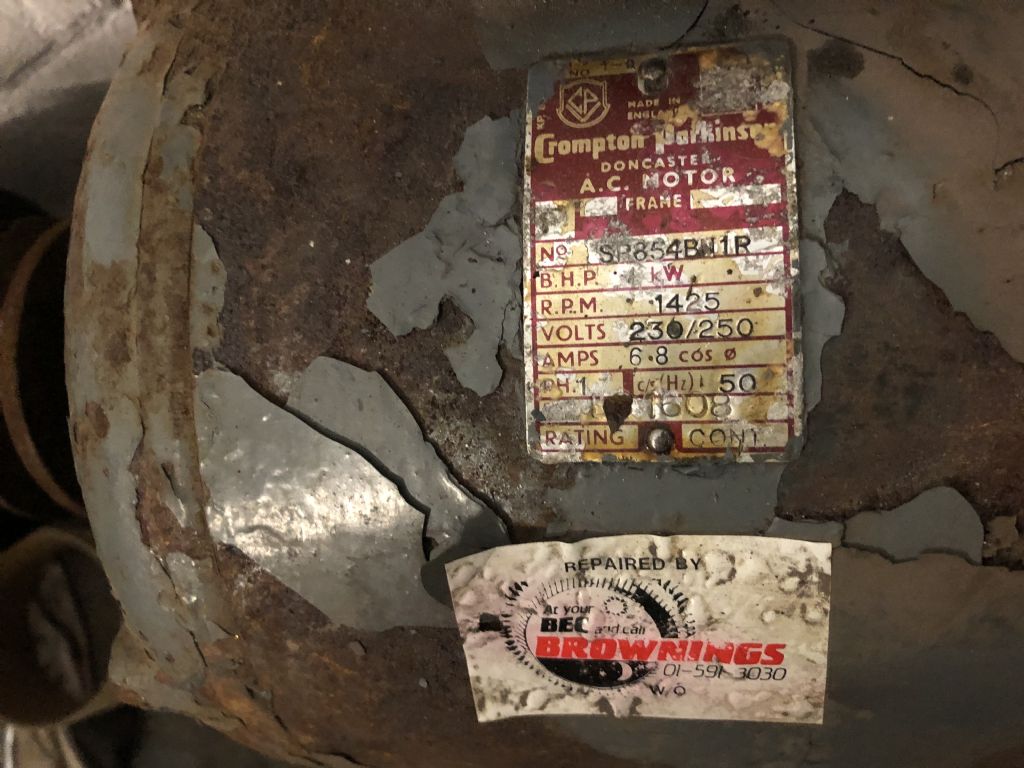

Also, can you see the wire colours on the motor side of the terminals? Crompton Parkinson favoured Blue, Red, Yellow and Black, where Black and Red are always the Run winding. Yellow and Blue are the Start winding, and reverse is achieved by swapping Yellow and Blue over. But the capacitor(s) and switch have to be right.

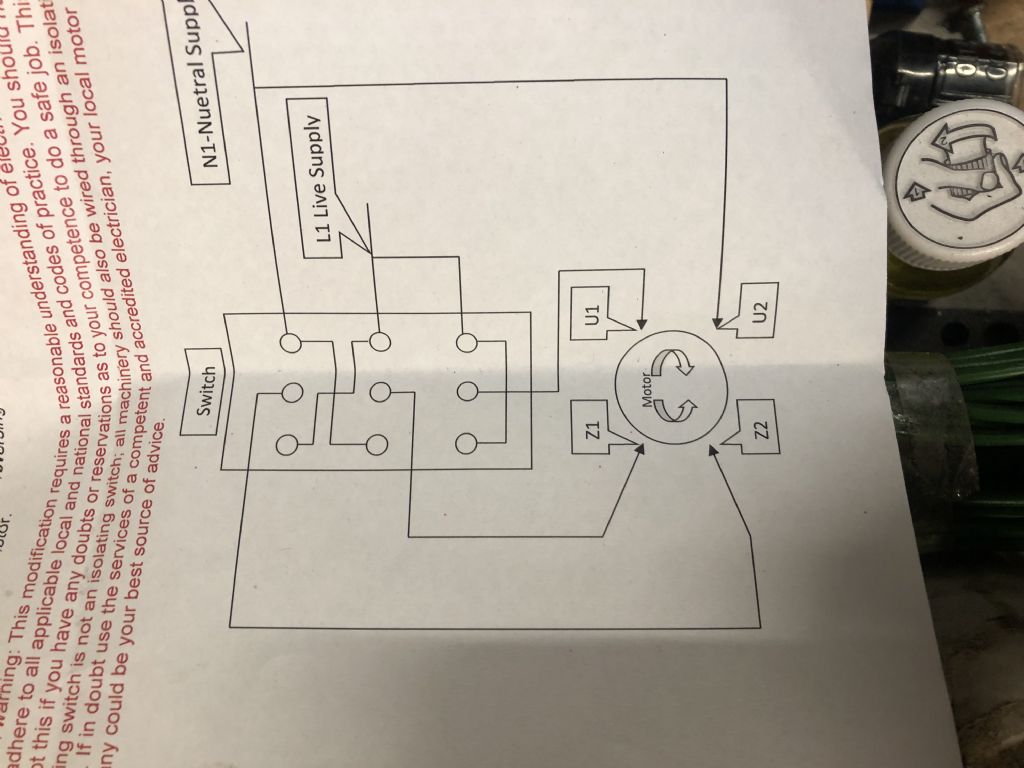

The switch diagram looks OK to me: U1 U2 are Run, and Z1, Z2 are start, but there's no clue as to what type of motor is connected, so we need to identify what type you have. Do you have a multimeter?

I hope Les Jones and the other motor experts will be along soon. Single-phase motor aren't my best subject!

Dave

TJ scott.