One of the collectors on The Stuart Models FB page posted an image of his new addition a few months ago and I thought it would make a good model.

No idea if it is based on any specific full size engine or was ever offered as plans or castings but the cylinder and valve chest do have the look of Stevens Model Dockyard about them so it may have been built using one of their sets of cylinder castings. I’ve named it after the guy who now owns it.

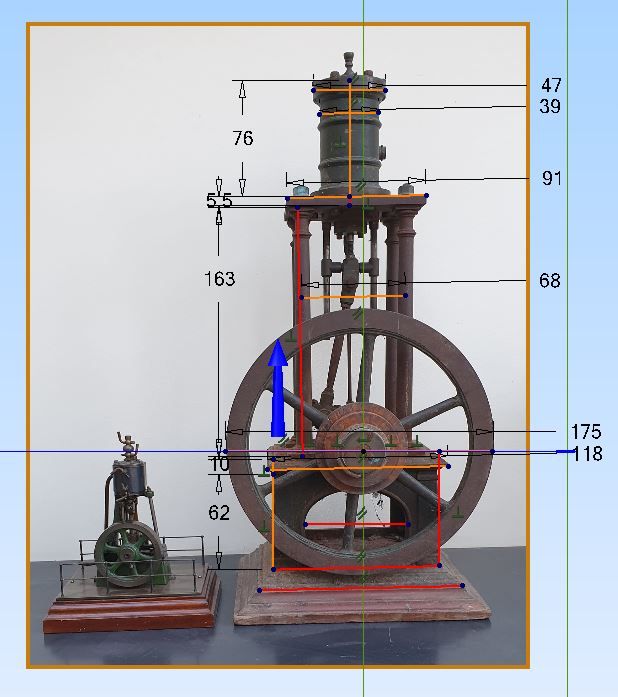

As it was on the Stuart Group and there was some interest from others who may want to build it I thought I should at least include one Stuart casting. The proportions are not quite right to use both a 7″ flywheel and their 2″ x 1″ cylinder as this engine has a larger cylinder so I drew it around the flywheel as that would probably be the harder part for people to make. First job was to put an image into Alibre and once scaled to suit the flywheel pull a few dimensions off it. This image also shows it stood against an early Stuat No10 for an idea of size, mine will be smaller. I’ve changed a couple of bits I did not like the look of but it is basically the same.

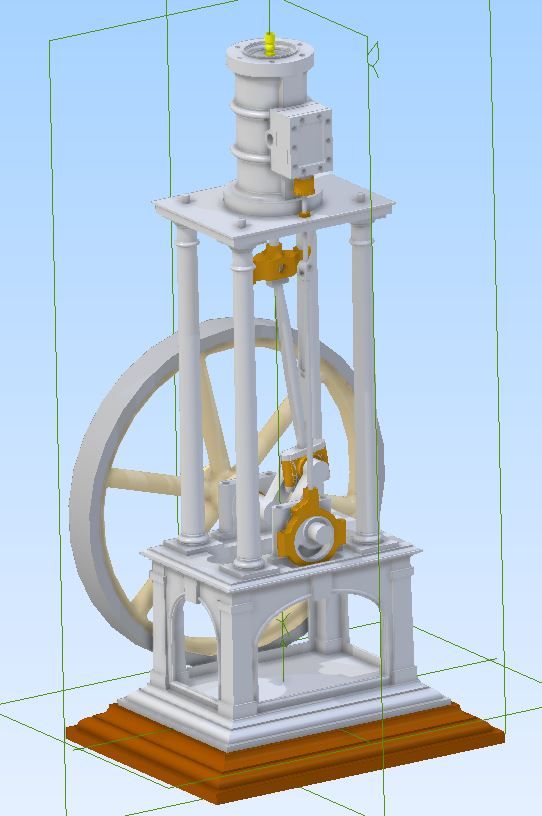

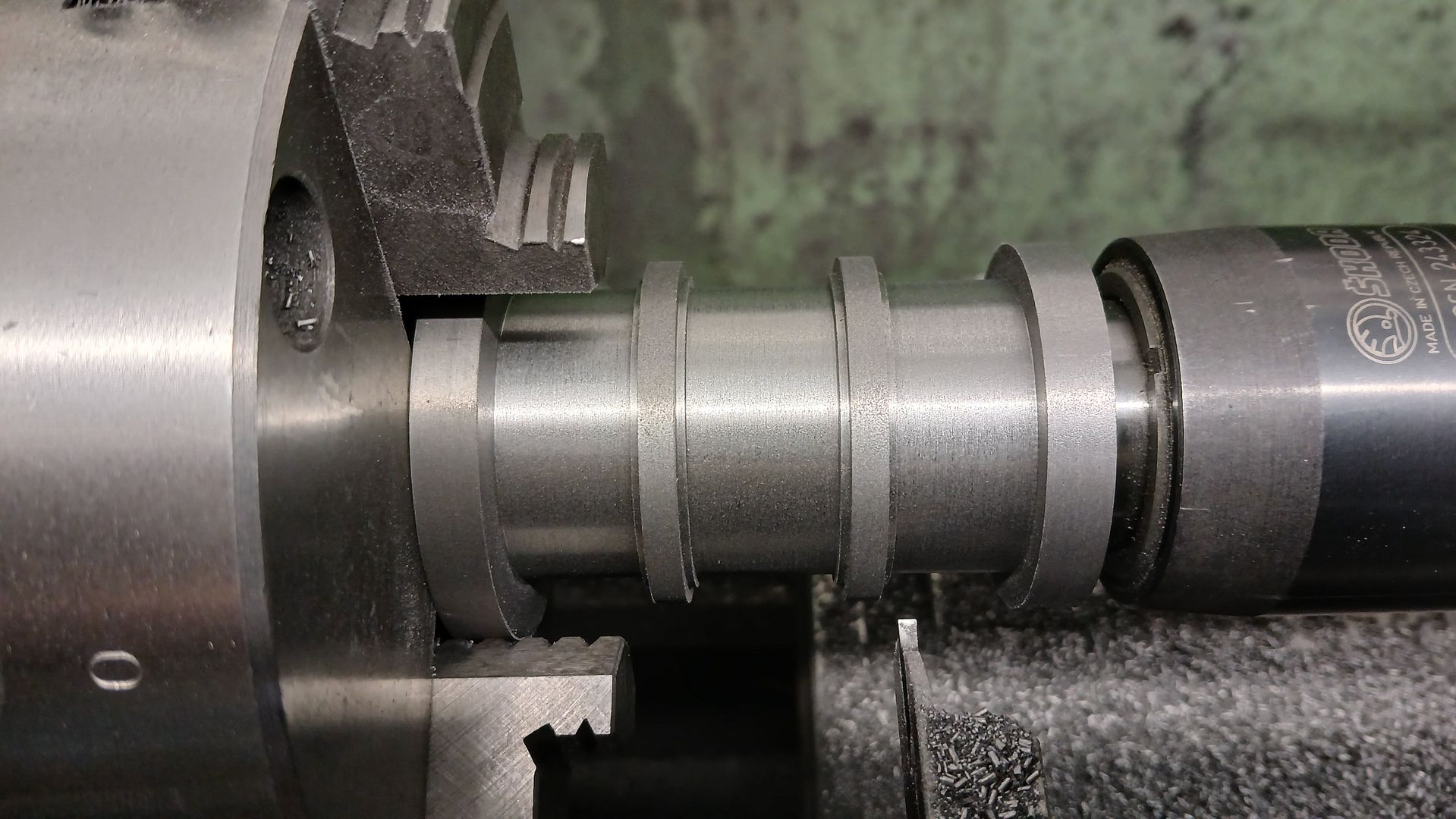

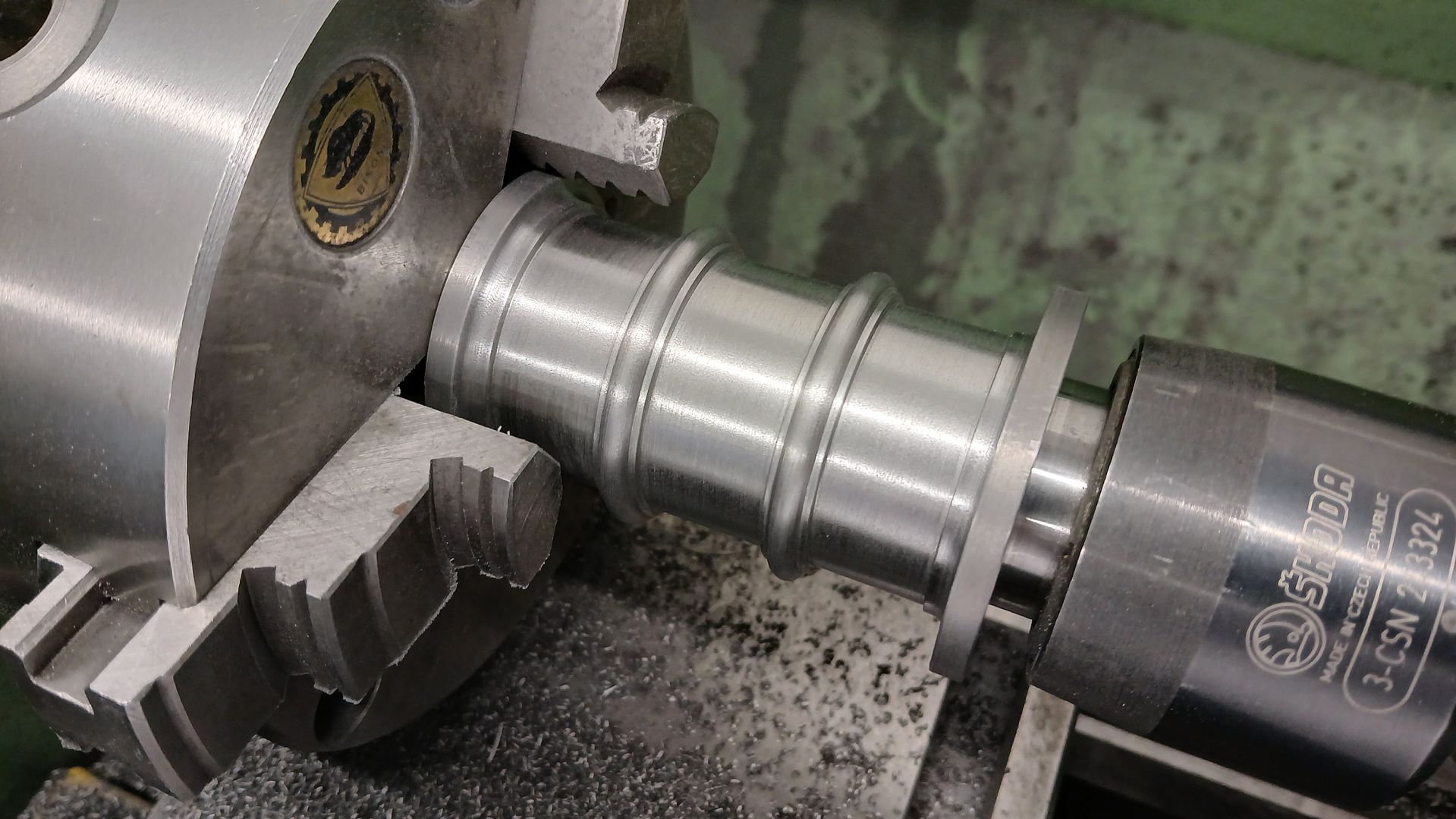

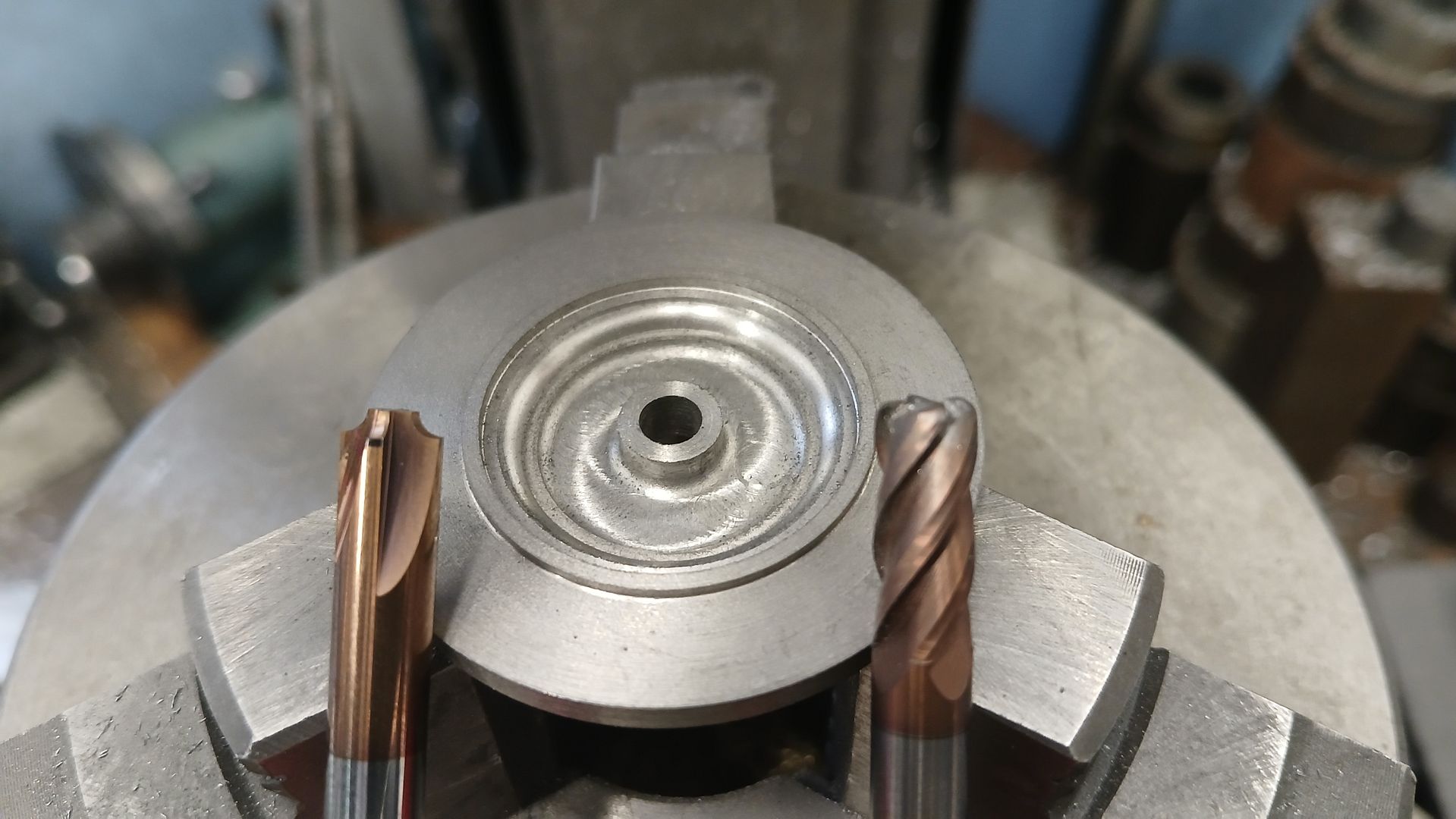

Over a couple of evenings the various parts were drawn up and assembled, had to spend quite awhile playing with conrod length and cross head guide spacing to make sure the two did not clash but I’m quite happy with the way it looks. I will probably make my own flywheel but the image is with a Stuart one. All metric as is now my norm.

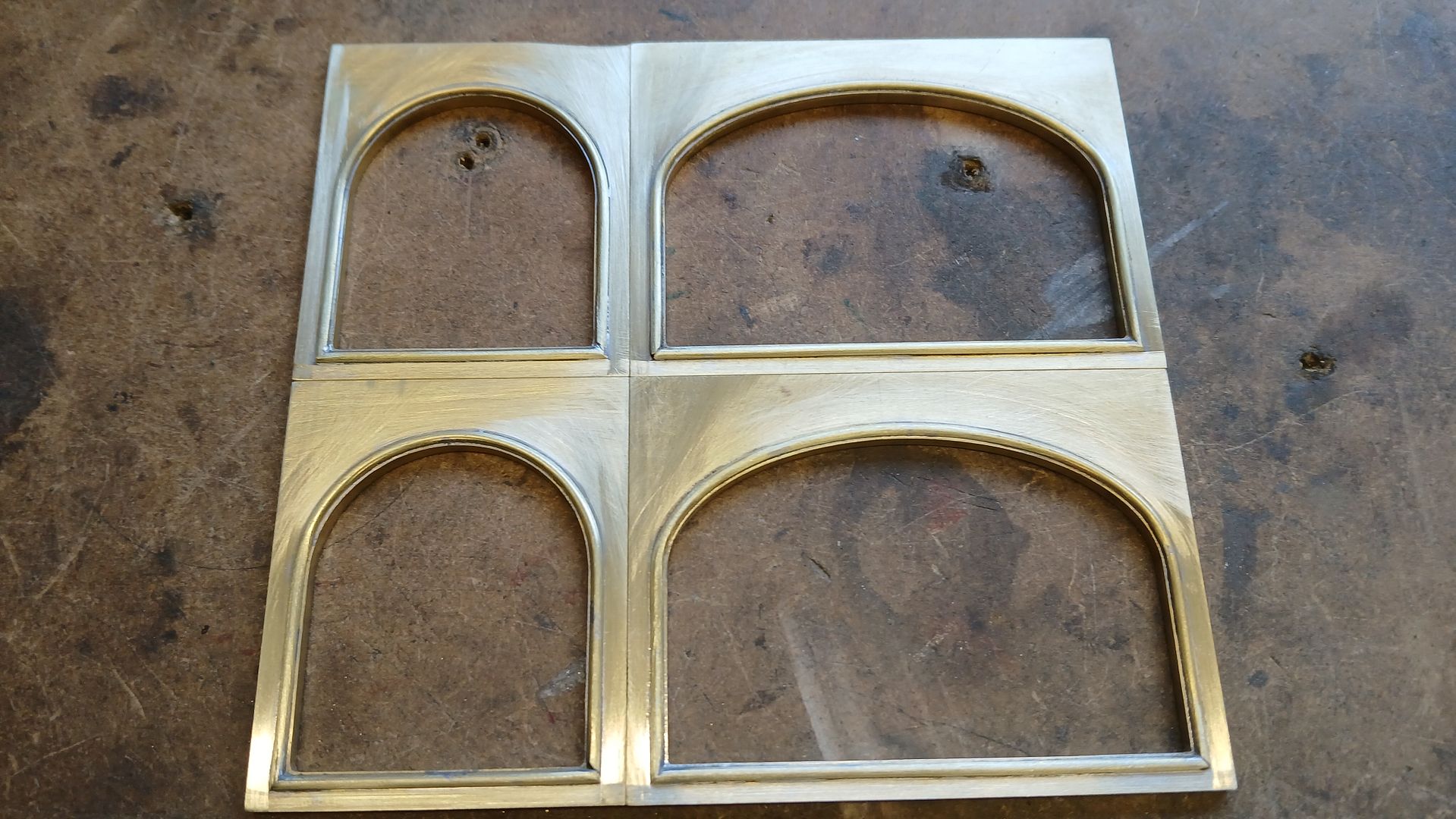

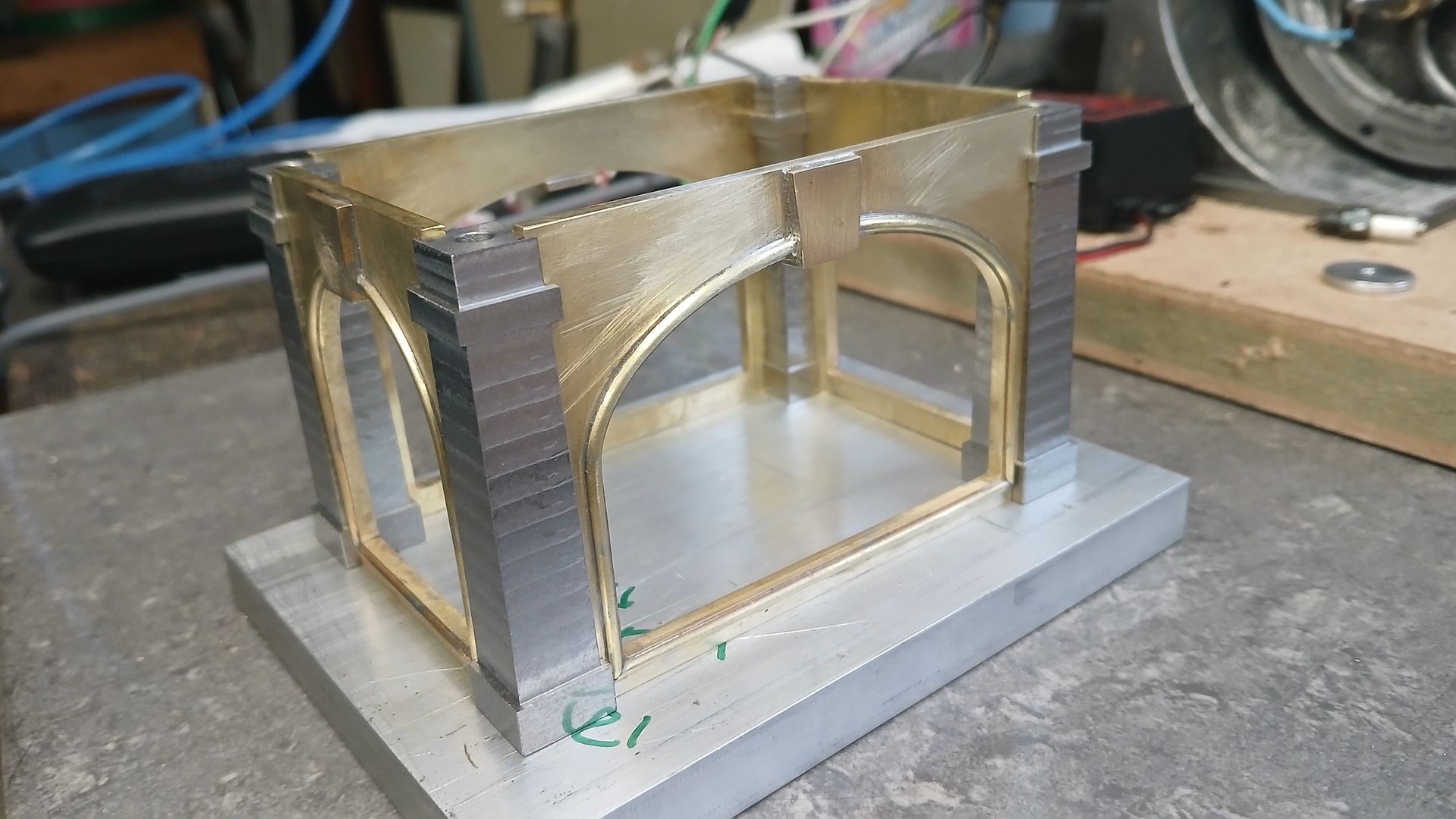

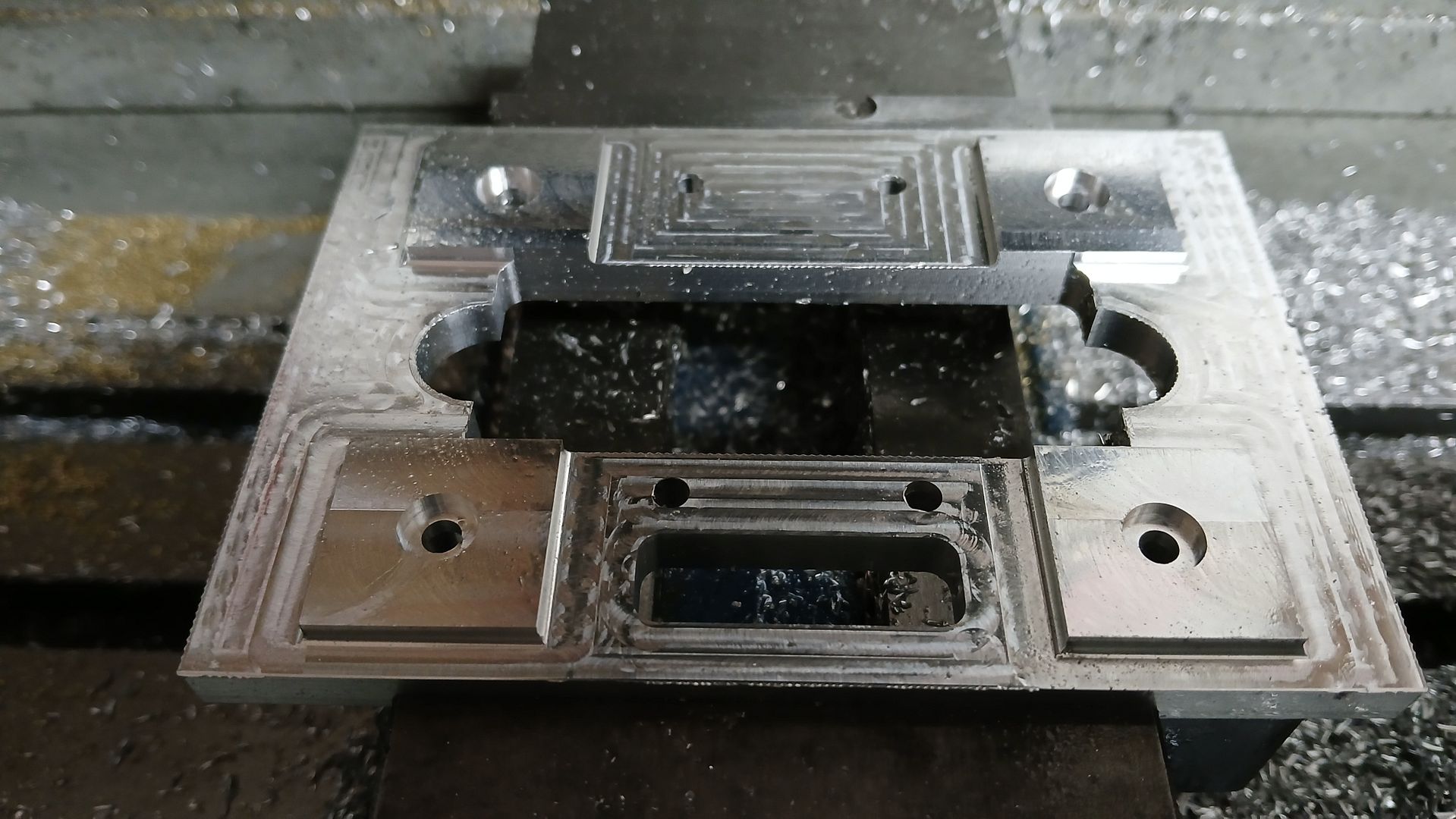

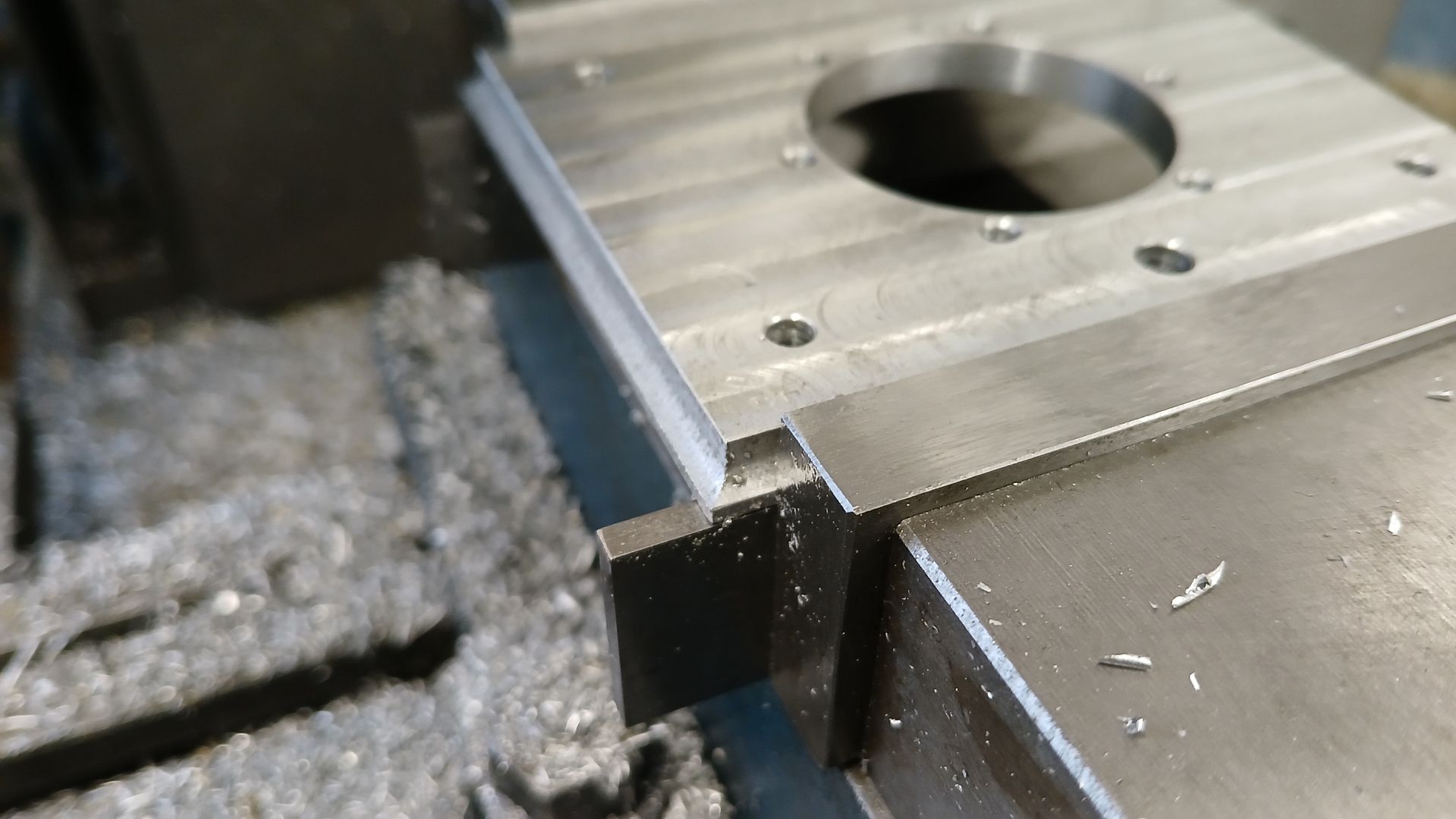

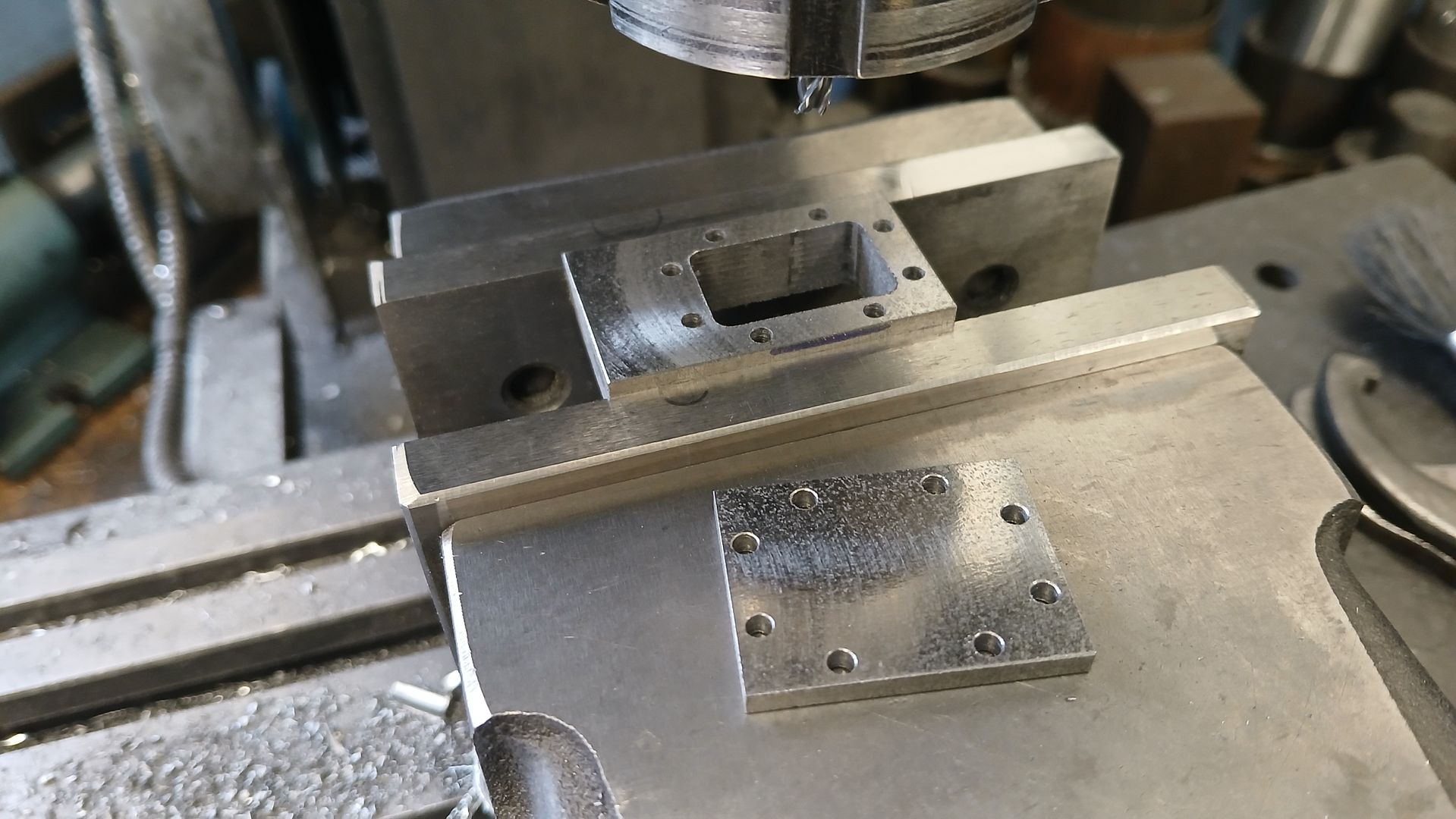

I made a start on the four panels for the base. The usual practice would be to bend up half round beading and fix around the openings. However 1mm radius beading is not available although not hard to make your own and it also has a tendancy to curl up when you want to to lay flat around a curve. Also the beading was set back only 0.5mm from the edge of the openings. After a bit of thought I came up with a cunning plan. Rather than use half round beading I thought I would try milling a 2mm wide x 1mm deep slot and simply solder some 2mm dia brass wire into the slot.

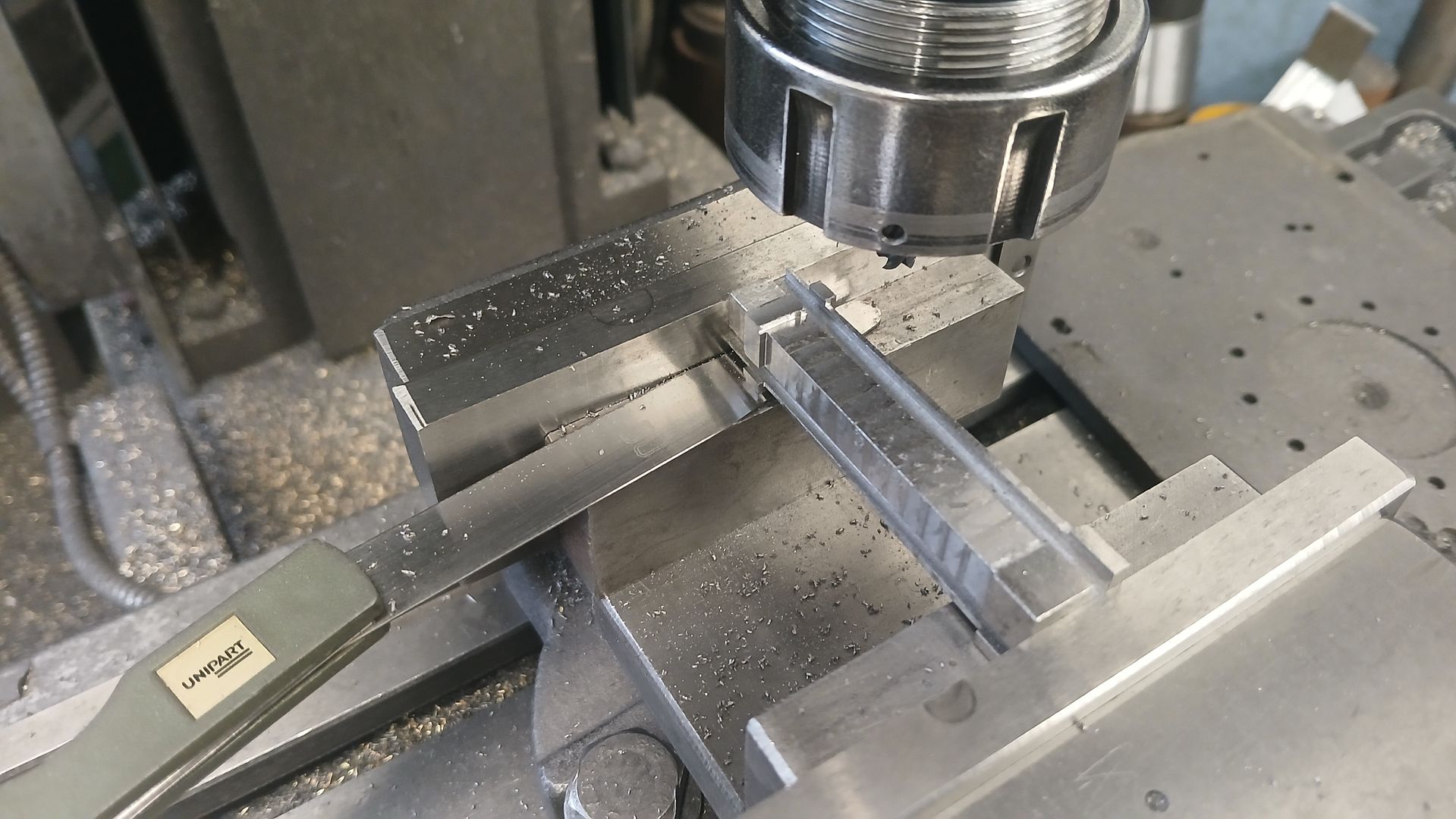

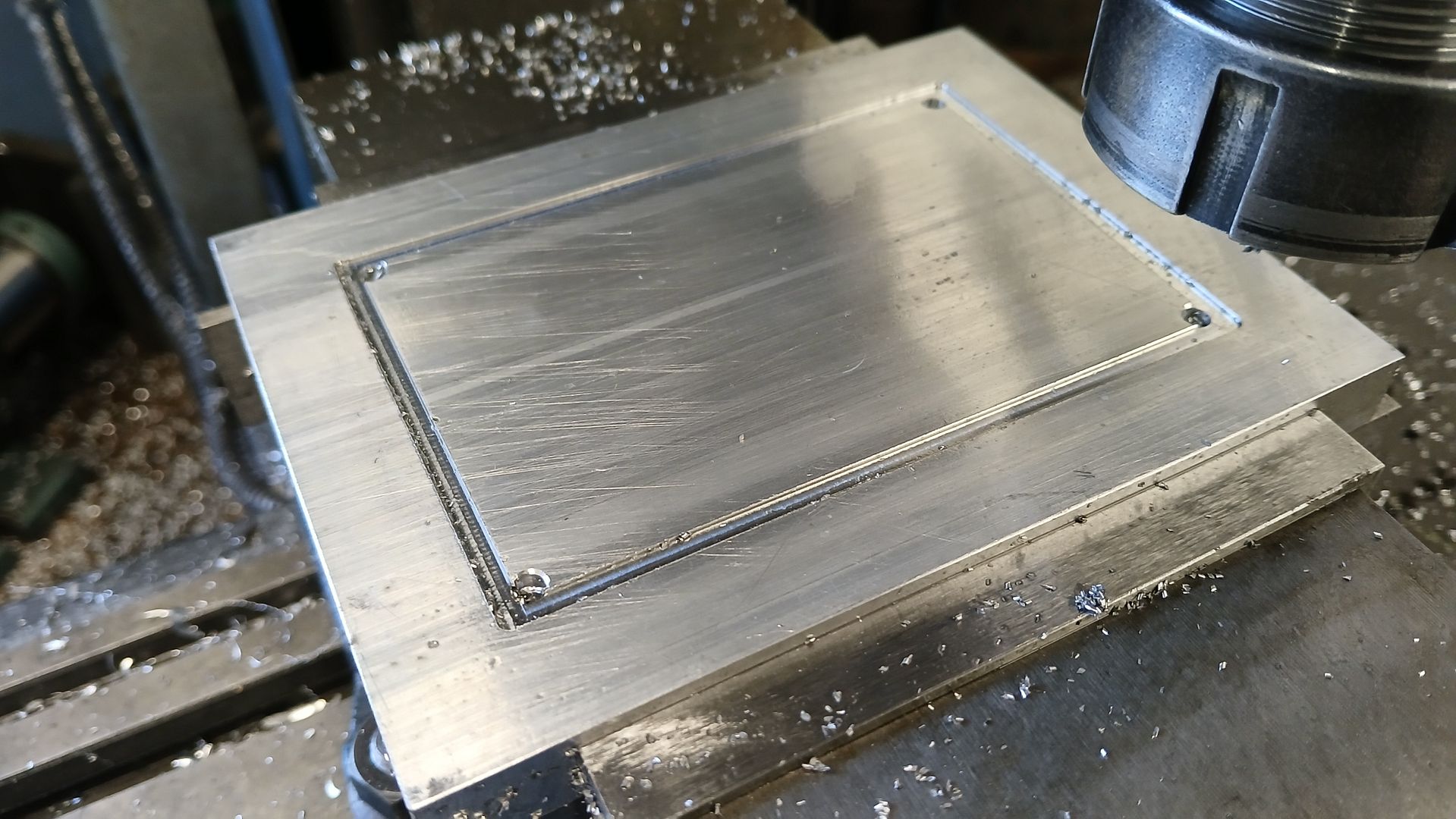

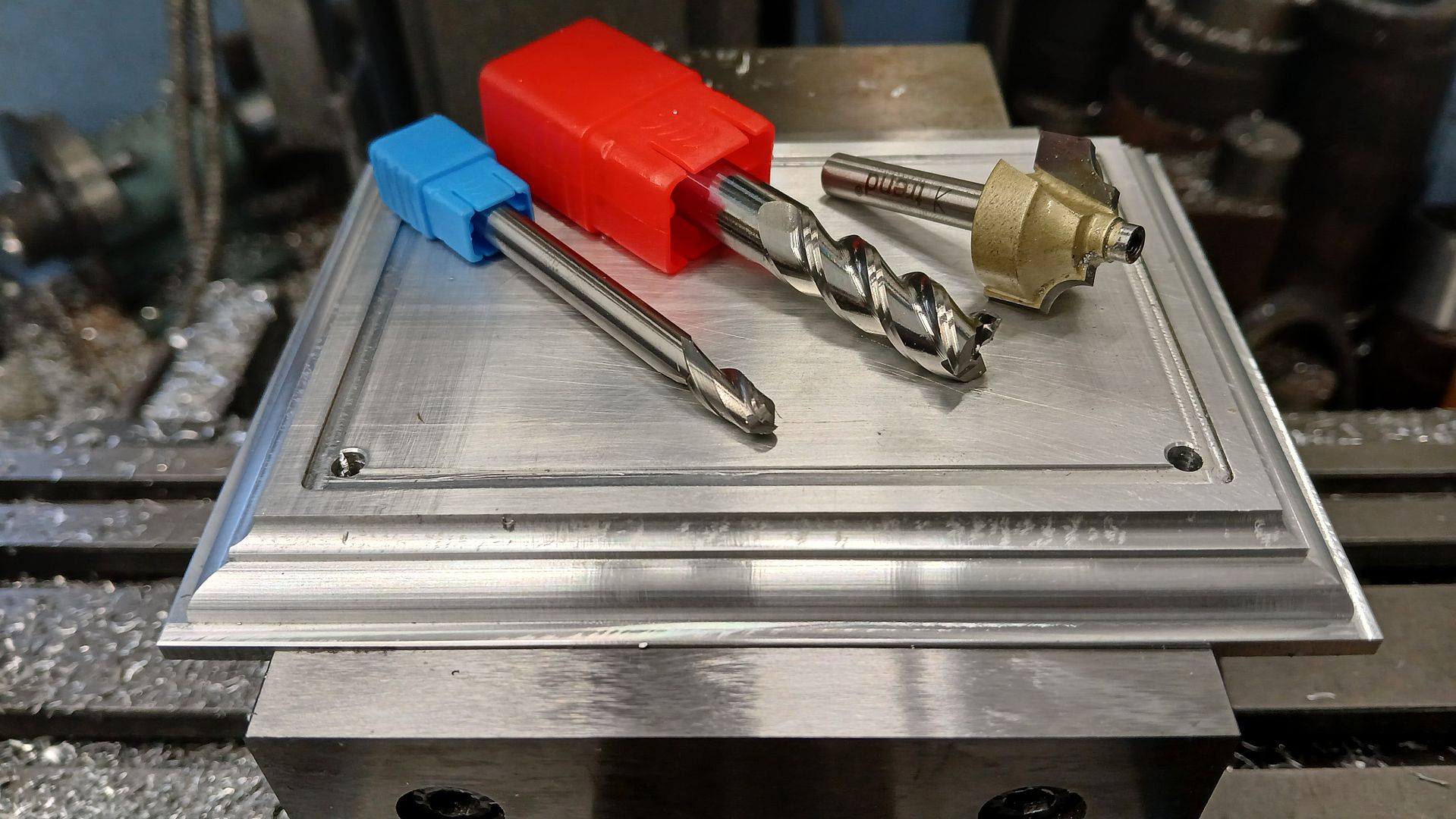

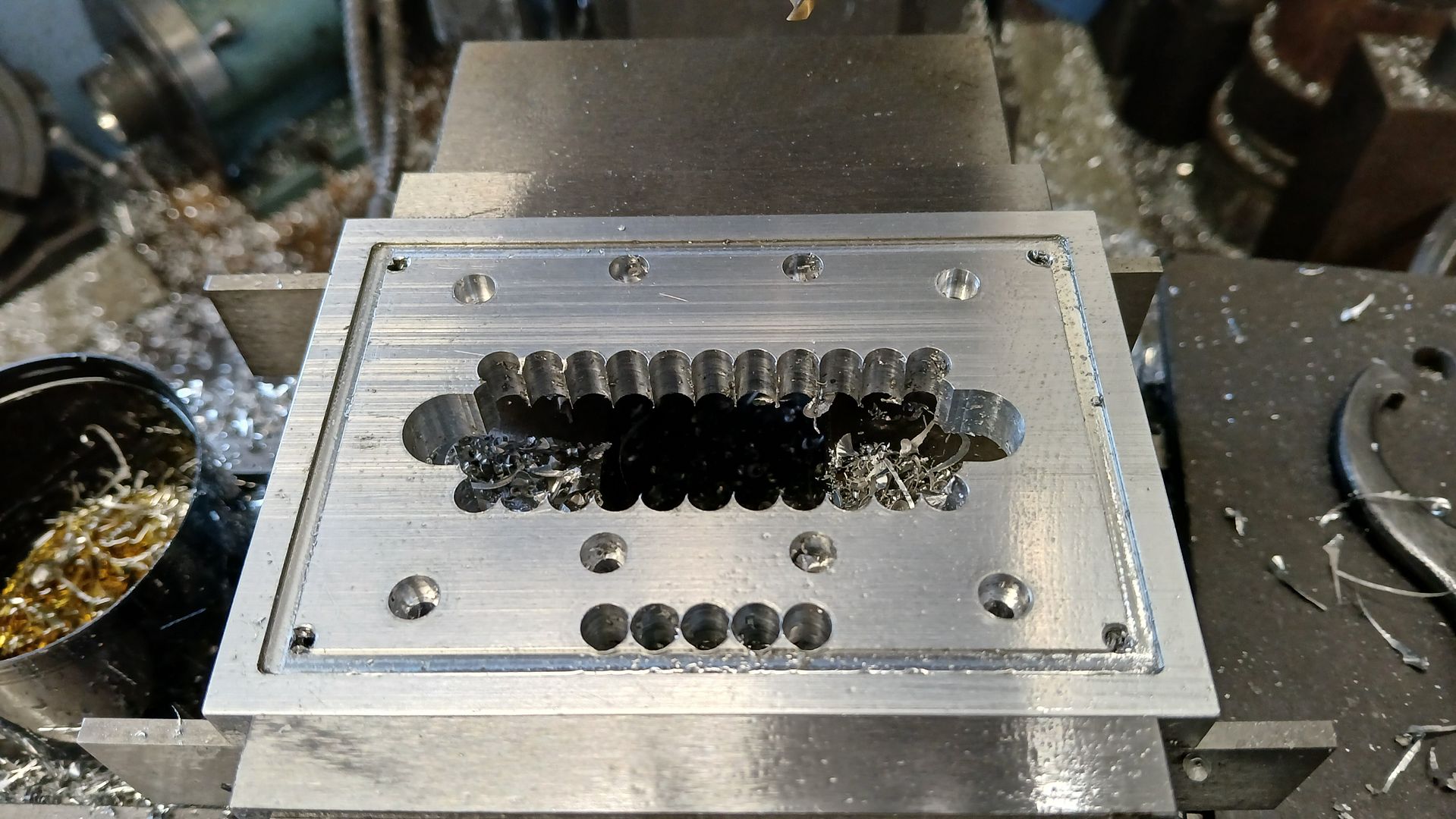

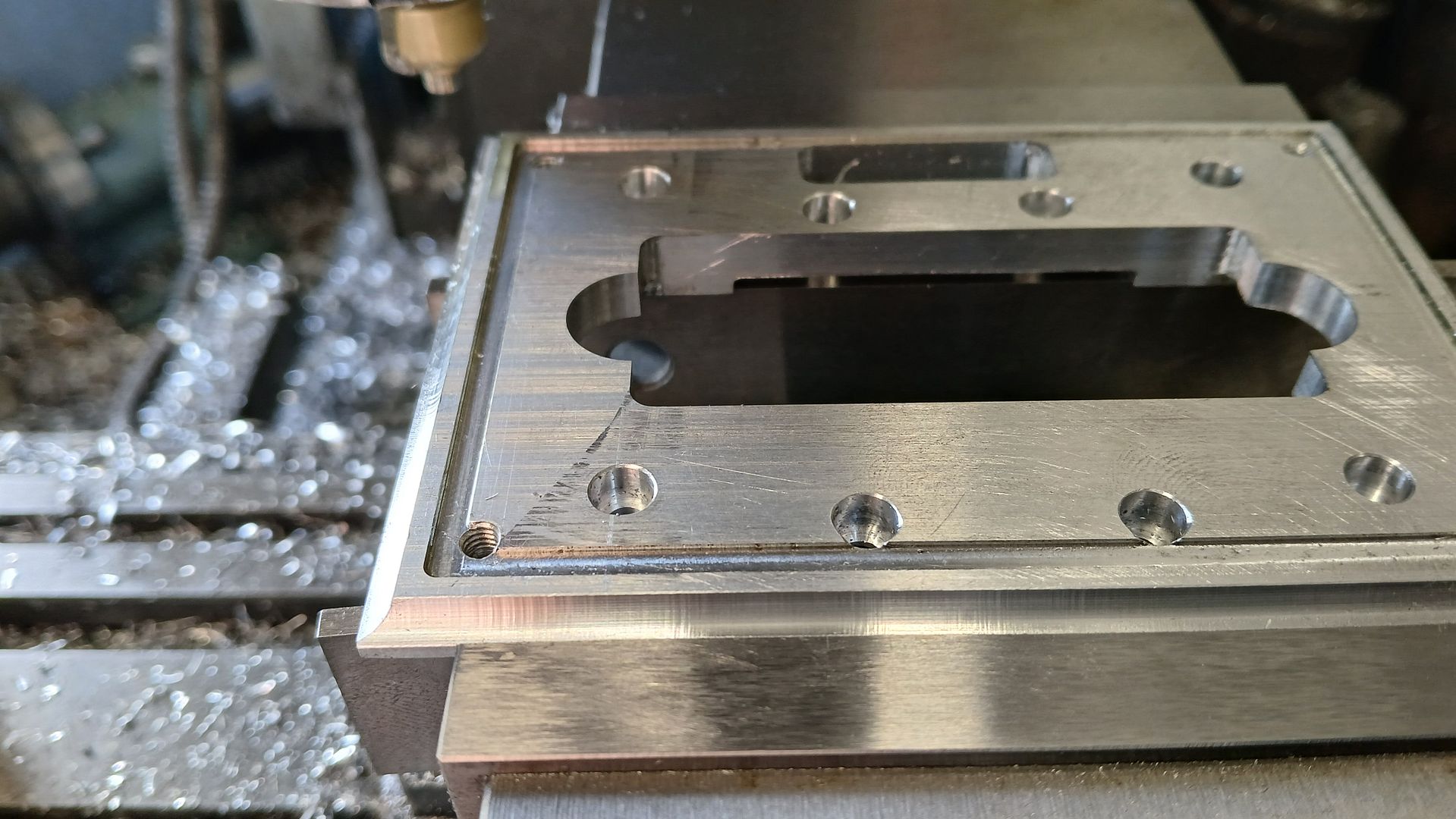

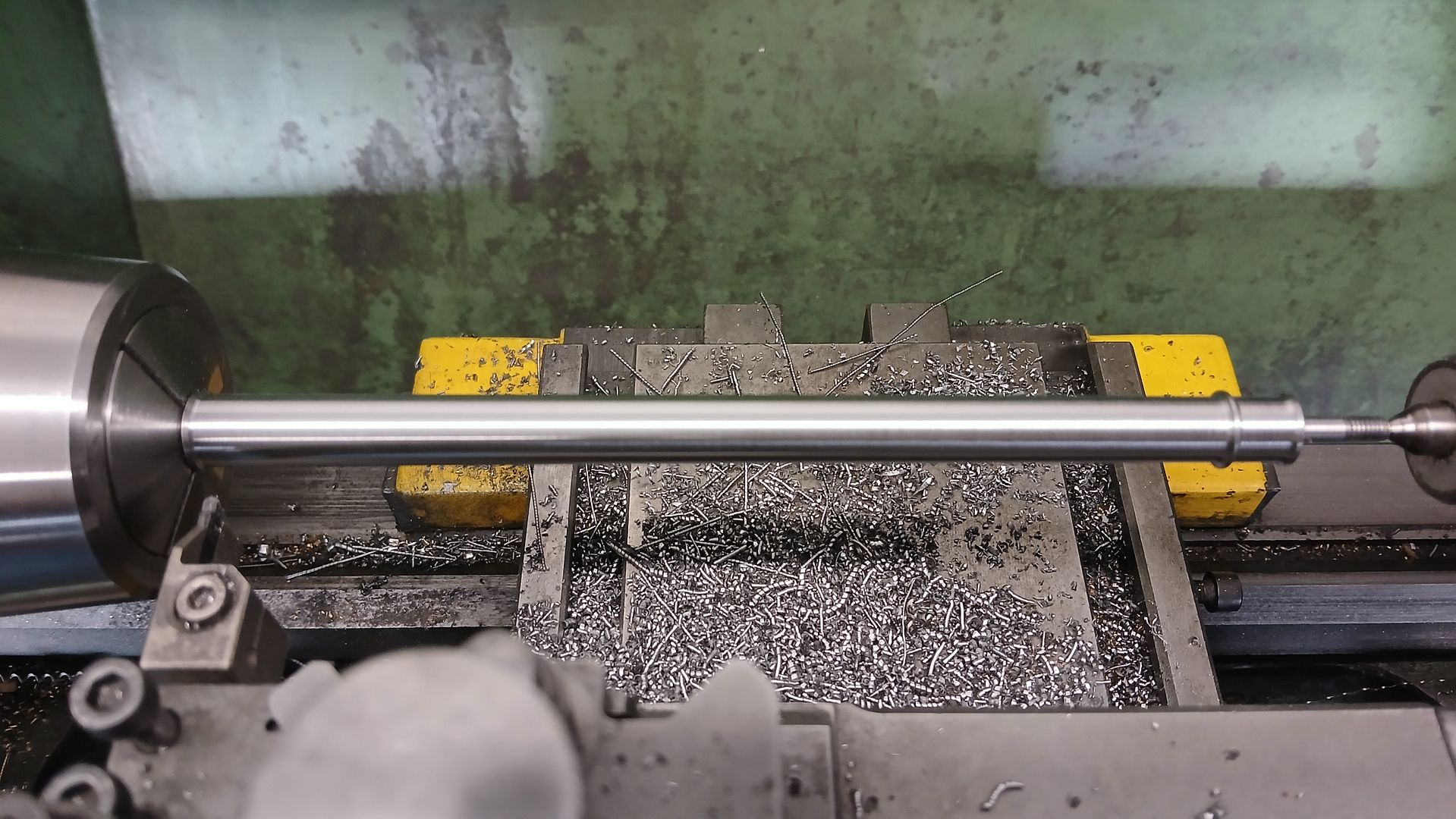

The four plates were sized on the manual mill and then over to the Cuts Nice Curves machine to do the slots and cut out the arched hole.

I use 4 or 5 tabs to retain the waste material rather than risk it coming loose and damaging the cutter or work, they are only 0.75mm high at the peaks so easily sawn through and tidied up with a file.

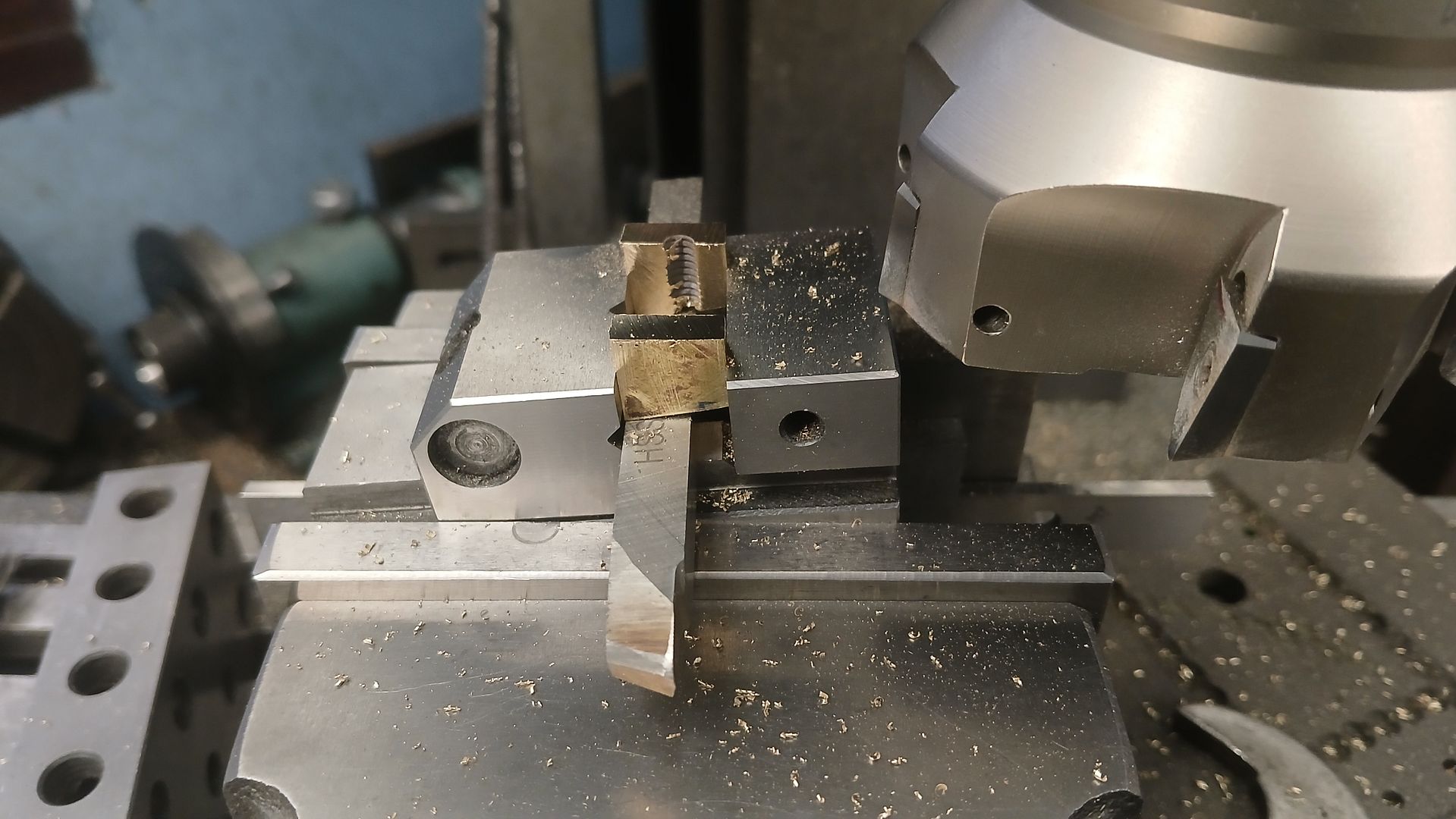

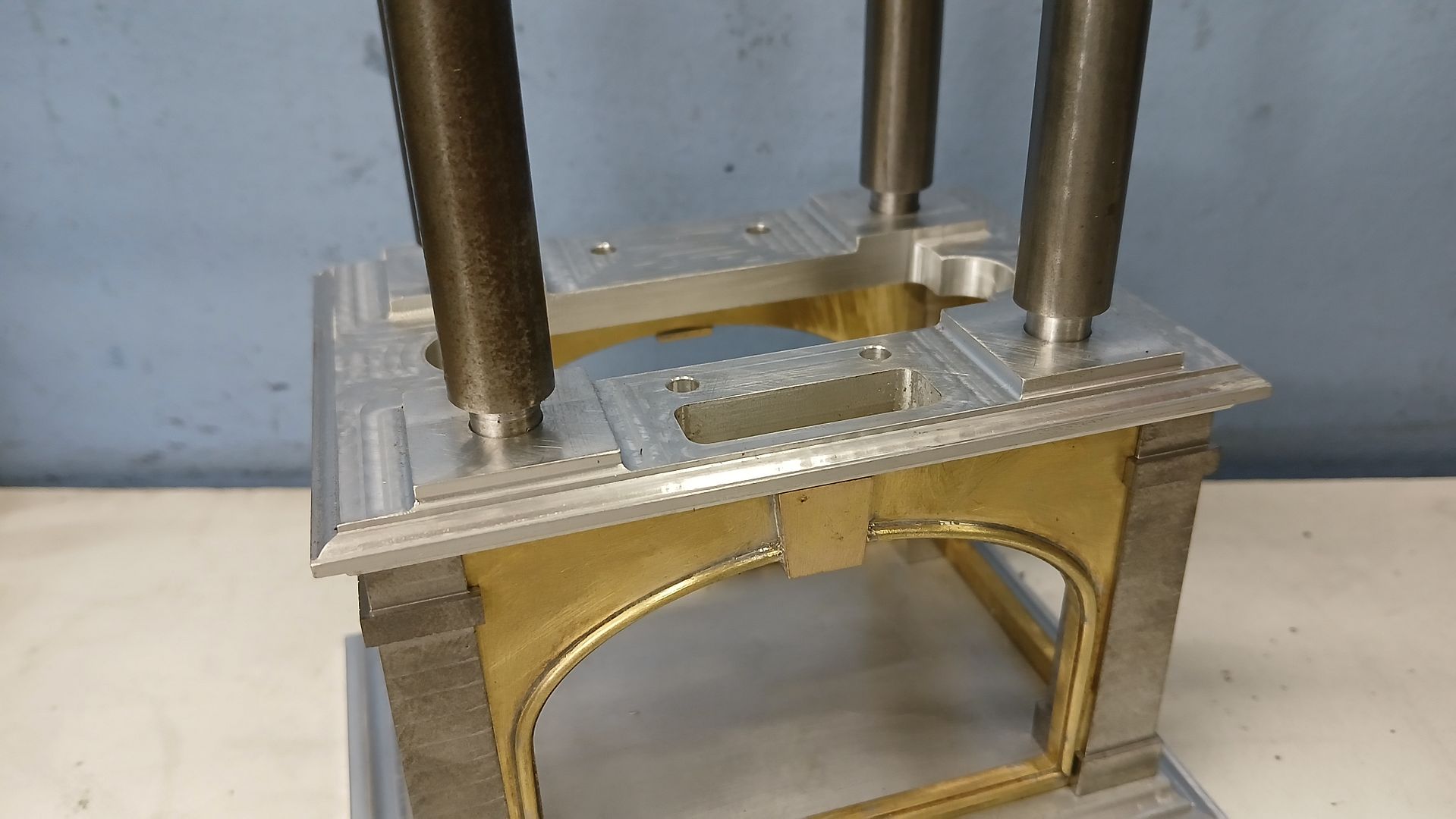

After straightening a length of the 2mm brass wire I filed one end to 45deg for the miter joint, clamped that end into the slot and it was then easy to push the wire down into the slot with one hand as the other guided it around the arch and back down the other side. Marke and miter the end then just a straight length for the bottom.

A bit of flux and some soft solder fixed it all together then a quick cleanup of the small amount of excess solder and they are ready for the “key stones”

Nigel Graham 2.