Posted by Mike Poole on 17/06/2017 23:04:15:

Has anybody actually experienced any problems with interference from their VFD if they have not followed recommended guidelines?

Mike

Just spent a happy couple of hours conducting an EMC review of my workshop.

I used an SDRPlay RSP1 covering 10kHz to 2GHz. The receiver is connected via a USB cable to an Acer Aspire V15 laptop running Windows 10. The RSP1, which is a Software Defined Radio, was managed by SDRConsole v3 set to decode Amplitude Modulation (AM). The antenna was 10m of wire looped around my dining room and it is about 8 metres distant from the lathe as the crow flies.

I make no claims for calibration not least because the antenna is a complete lash-up. Therefore my assessment of my lathe's EMC as 'very poor' does not mean that it is out of specification, only that I'm not impressed.

Results:

- The laptop's switch mode power supply lifts the radio noise floor by 10dB, the racket gradually fading away at about 150Mhz. (Poor) Therefore the workshop tests were run with the laptop on battery only.

- I can just detect 6 tubes of fluorescent lighting around 125kHz. (Very Good)

- I can detect an impulse when the grinding wheel is started, but it is otherwise fully suppressed. (Very Good) Ditto the band-saw.

- My cheap pillar drill is nearly as good as the grinding wheel (impulse start detected), except for minor noise centred around 500kHz. (Very good)

- My small belt-sander is nearly as good as the grinding wheel (impulse start), except for some hash centred around 3.6MHz. (Very good)

- Best of all – no interference detected – was my Milling Machine. It has an 1100W brushed DC motor. (Very good)

- In comparison the 1500W VFD in the lathe is very poor, see pictures and comments below.

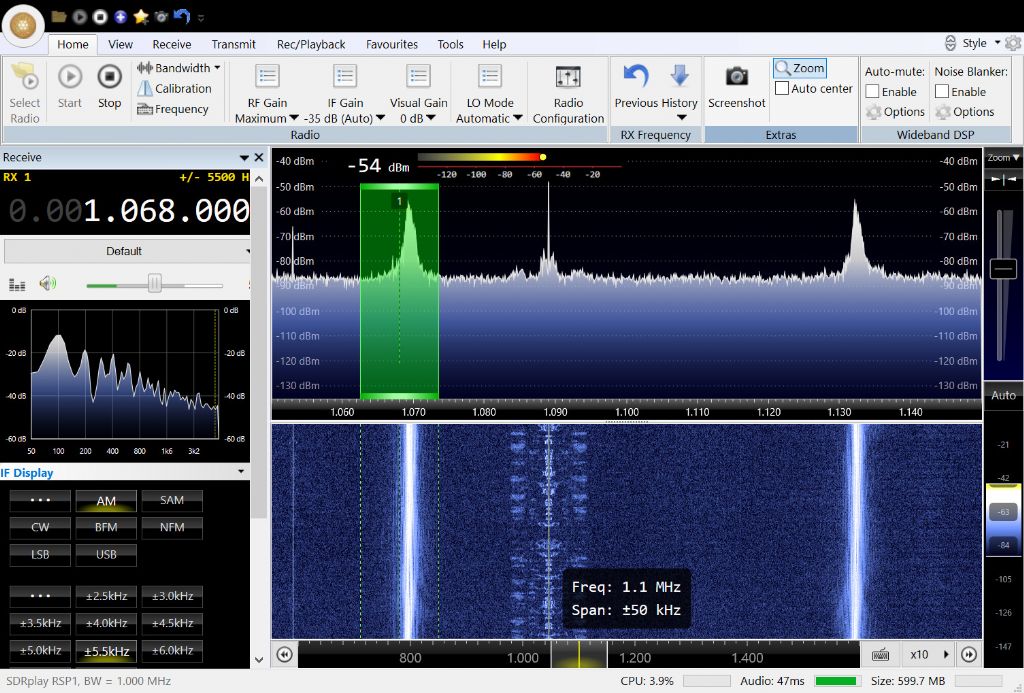

When the lathe's electronics are switched on but the motor is off, a series of moderately strong signals appear. They are unstable, about 80kHz apart and peak in strength at about 1MHz . This is inside the medium wave broadcast band. The strongest spur measured -54dB compared with a nearby radio station at -48dB. (ie the radio station is only twice as loud as the lathe. There is potential for interference even before the motor starts.)

In the picture above the two strong white lines are interference from lathe and there is an AM broadcast station between the spurs. By luck the lathe is not interfering with that particular broadcast, phew!

Unfortunately the interference gets much worse when the lathe's motor is switched on.

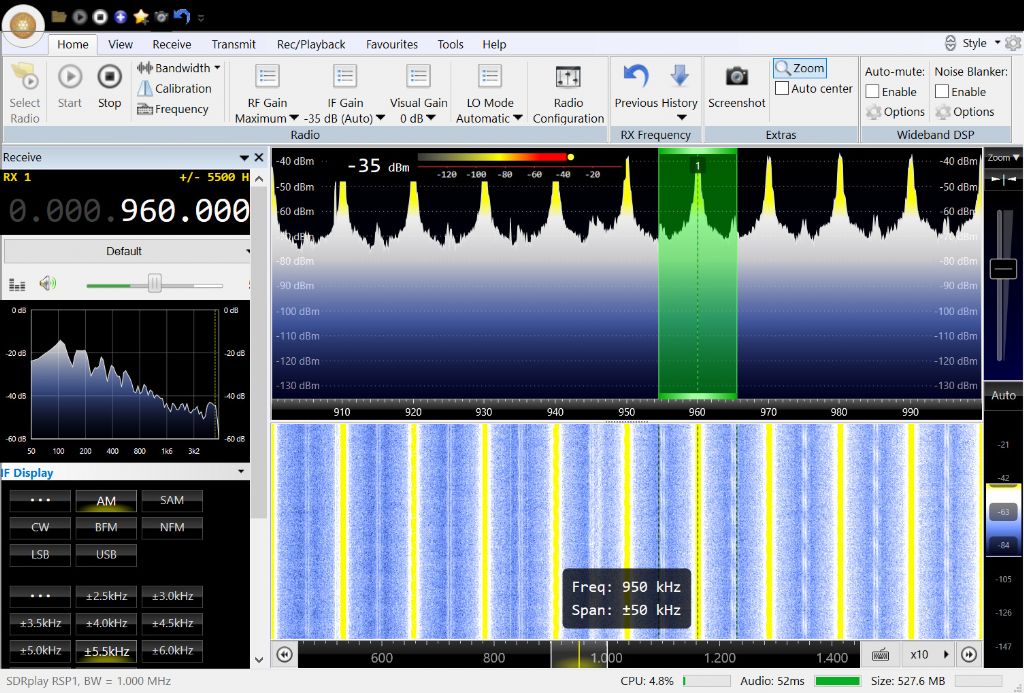

The picture shows heavy interference. It starts at 10kHz with harmonics every 10kHz. Although the signals peak in the medium wave band, they remain powerful up to about 20MHz and can still be just detected at 50MHz. Bad news. The interference is considerably strong than broadcast radio in the medium waveband and all stations are wiped out.

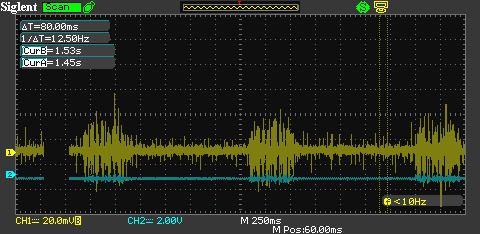

The signals are far from pure being modulated with bursts of noise every second or so.

Being inside the house the antenna emphasises near source radio interference. Next step is to see how far away from the house I can detect lathe generated interference on an AM portable. If the interference is being carried by the mains cabling rather than radiated directly it could be quite a long way. Like miles! I'm hoping that I'm picking up short range interference and that the VFD filter is keeping most of the muck out of the mains wiring.

My workshop DAB radio is not interfered with. DAB signals are broadcast at about 240Mhz which is too high to hear the lathe's VFD. There is no problem with TV. I haven't tested the effect on the Internet yet.

Before throwing rocks at the lathe and it's VFD I need to do more checking. One obvious problem is that in the workshop the lathe is on the end of a longish lead, and that the workshop itself is in an extension somewhat distant from the consumer unit. The actual earth could be 30 metres away from the lathe, fine as a safety earth, but total poo when it comes to grounding radio frequencies. Or it might not be that at all.

It's too early to suggest a fix, or even to conclude the bad results matter much in practice. Interesting though…

Dave

SillyOldDuffer.