Posted by petro1head on 12/12/2019 20:23:29:

Posted by Clive Brown 1 on 12/12/2019 19:35:27:…

…

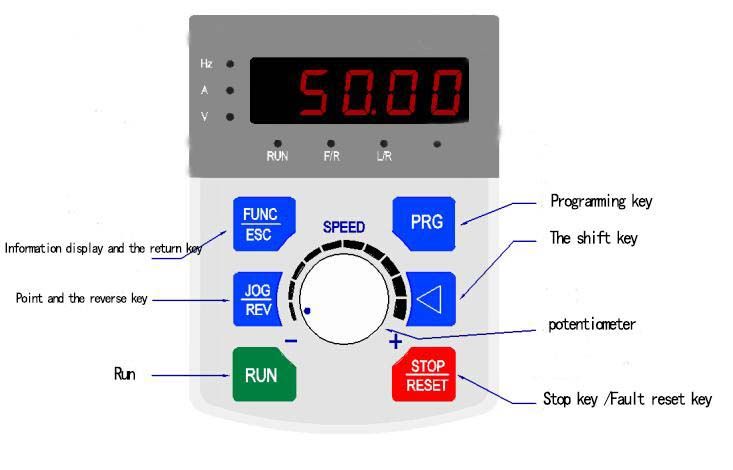

These are the options under Frequency Setting Mode:

0:Frequency setting(UP/DOWN)

1:Panel potentiometer

…

I have it set to 1

…

Edit: Just set the option to 0 and now it remembers the last Frequency setting. Not very intuative if you ask me but not complaining if it works

Edited By petro1head on 12/12/2019 20:31:47

That's logical:

- Option 0: Rotary encoders detect right/left movement not position. As encoders only signal turning steps the VFD controller has to set and remember the frequency in software. Then the controller converts right/left rotary clicks into up/down frequency steps relative to the frequency it stored in memory.

- Option 1: A potentiometer returns a voltage directly related to it's physical position. The controller derives frequency straight from the voltage and has no need to remember anything in software. In effect, the potentiometer is the memory.

Selecting option 1 told the controller it had no need to remember frequency. But you're right to say this behaviour is somewhat counter-intuitive. It would have been more user-friendly had the controller been programmed to ignore the rotary encoder when Option 1 is selected (and vice versa). Maybe there's a Use Case where it's handy to set the frequency with a pot and then to vary it with the encoder? Don't see it myself!

Trouble with potentiometers is their tracks wear and go intermittent, especially in a dirty workshop. Sooner or later, even the best have to be replaced. Encoders are a good deal more robust, but the controller has to be brainy enough to understand them. Not a problem now that microcontrollers can be had for well under a pound: very common today to find electronic controls implemented with rotary encoders rather that pots.

As an aside, rotary encoders come in two main families. Most common are a cheap plastic type with low resolution (perhaps 20 counts per revolution), low turning speed, and click detents . These are intended for manually operated controls. Also available are precision encoders, about 25x more expensive, with high resolution (up to 2000 counts per revolution) and capable of spinning up to about 3000rpm. This type is used for precision control or precision monitoring, as needed to make an Electronic Lead Screw.

Dave

SillyOldDuffer.