VFD recommendations

VFD recommendations

Home › Forums › Electronics in the Workshop › VFD recommendations

- This topic has 37 replies, 24 voices, and was last updated 11 February 2021 at 10:41 by

Hollowpoint.

-

AuthorPosts

-

12 January 2019 at 02:24 #31998

Pete.Participant@pete-2

Pete.Participant@pete-2VFD advice please

12 January 2019 at 02:24 #390630 Pete.Participant@pete-2

Pete.Participant@pete-2Looking at getting a VFD to run a small 3 phase mill, are the generic Chinese units on ebay any good? anyone have any recommendations on what to buy or what to avoid?

Thanks.

12 January 2019 at 07:06 #390637not done it yet

Participant@notdoneityetDepends. No such thing as ‘generic’ – they can all have different or more facilities than the cheapest. Chinese can be good, but the cheapest likely will not be as good as you might wish.

You need to get the correctly sized unit for your application. If you require more safety functions, avoid the cheapest.

23OV inverters are generally much cheaper than 415V equivalents.

More info on your particular installation would be good.

12 January 2019 at 07:14 #390638Raymond Anderson

Participant@raymondanderson34407I have 3 in use 1 Siemens, 1 WEG CFW08 and a Eurotherm 650 [ now made by Parker SSD ] all perform superbly and have done since each was installed [ many years ago.. try 2001 for the Eurotherm ] and circa 2007 for the other 2 . Cant comment on any other makes.

12 January 2019 at 07:33 #390646Robert Hurst 1

Participant@roberthurst1Hi Peter, by generic I guess you mean the units manufactured by Huanyang amongst others.

These offer very good value for money, however the electronics is a bit marginal so I'd recommend buying a unit rated twice that of the motor, especially if running from a single phase supply.

Beware of vendors claiming that their unit will step up from 230 V to 415 V, this is simply not true. Check your motor can be re-configured for 230 V (delta or mesh connection). A 415 V motor will run on 230 V but will lack torque.

Cheers.

12 January 2019 at 08:37 #390653David Jupp

Participant@davidjupp51506Having worked with a few VFDs in my professional life, I'm aware how much easier things are to set up, and to diagnose, if you have the option of connecting a PC with manufacturers software to the unit. The software is usually free, but a special lead or adaptor may be required – it seems to be the more 'mainstream' manufacturers that provide software for easier configuration and diagnostics. Some manufacturers offer wireless connection to your smartphone for set-up/diagnostics.

Safe Torque Off (STO) is a safety feature worth considering.

12 January 2019 at 09:44 #390662Chris Evans 6

Participant@chrisevans6Plus 1 for Huanyang. I have run my 2HP Bridgeport from one for around six years now without issues. It did however take a friend who has got 5 of these running his various machines to set it up. He understands the "Chinglish" in the instructions. Prior to getting the Huanyang VFD I tried running the Bridgeport off a Transwave static inverter without success. The static inverter does run my 3HP lathe though, one day I will either take the motor off the lathe and see if the "Star Point" can be found to configure it to run 240 volts or change the motor for one that can. I would love the soft start and other features of a VFD on my lathe.

12 January 2019 at 18:17 #390761J BENNETT 1

Participant@jbennett1A good place I have found to look is "inverter drive supermarket" https://inverterdrive.com. They have a very wide range available. Some makes, such as Invertertek, are actually designed and made in the UK. Full on-line documentation is available for most products which is very useful, although some of the manuals run to many hundreds of pages and are fiendishly complicated. One make I have been looking at most recently is Lenze, which are German. They have the remote software referred to above, as do some others. The Lenze documentation is however, very detailed in the usual German manner. It is refreshing however, to have manuals that are written plain English.

I should point out that I have so far never purchased any thing from this company nor am I in any way associated with them. But I have found it a very useful resource in researching VFDs.

12 January 2019 at 19:00 #390769Bikepete

Participant@bikepete+1 for Inverter Drive Supermarket.

FWIW I dislike VFDs which ONLY have configuration via computer. Much prefer having a basic keypad and display on the unit itself, even if operation is more cryptic and it costs a tenner or two more. Main reason is that when you come back to it several years later for whatever reason you don't have to worry about whether you have lost the cable, whether your computer operating system is still supported or indeed whether your new computer even has the necessary ports for the cable to connect to, whether the software licence is still valid and free of charge, etc. Instead all you need is the instructions (almost always downloadable if lost).

Have had good experience with Yaskawa models over the years, but many others too. A few years ago I tried one of the WEG ones which often come up as lowest price on Inverter Supermarket – it works OK but in comparison it is a bit basic in functions and instructions quality.

I would strongly recommend budgeting for a proper enclosure for it too – very few VFDs are designed to be exposed to workshop conditions unprotected.

Edited By Bikepete on 12/01/2019 19:02:28

12 January 2019 at 19:34 #390770not done it yet

Participant@notdoneityetPosted by Robert Hurst 1 on 12/01/2019 07:33:32:

Hi Peter, by generic I guess you mean the units manufactured by Huanyang amongst others.

These offer very good value for money, however the electronics is a bit marginal so I'd recommend buying a unit rated twice that of the motor, especially if running from a single phase supply.

Beware of vendors claiming that their unit will step up from 230 V to 415 V, this is simply not true. Check your motor can be re-configured for 230 V (delta or mesh connection). A 415 V motor will run on 230 V but will lack torque.

Cheers.

Sorry but not true and possibly misleading. One should not necessarily double the inverter power over that of the motor. Overload conditions may burn out the motor and then the VFD!

The clear suggestion that inverters cannot supply 415V outputs is tosh. I ran my lathe on a 415V inverter, simply because I was told the star point could not be split to enable delta connection. They DO. But the inverter was rather more expensive than a 230V equivalent.

Most, or all, good manufacturers offer both output voltages in the usual range. Just don’t expect an inverter marked as 230V three phase output to work at full power, if connected to a 415V star wired motor. Power will be down by about 40%.

Getting the correct inverter for the application is important.

I have five inverters running off single phse supply. Only one supplies 415V. It is the one marked 415V output.

12 January 2019 at 19:59 #390775Neil Lickfold

Participant@neillickfold44316I bought Eric drive VFD made by Rich electric. I only got this as the company that I got the replacement 3ph motor from sells them. Told them what I wanted to do, they matched the settings for my application, and then showed me where and how to adjust it. Like the ramp up or ramp down, start and stop. Also how to connect the microswitch for the stop with the carriage in the forward direction, etc

I have a few more now, and are very happy with these.

a picture of my lathe set up is in my album.

13 January 2019 at 13:35 #390855Robert Hurst 1

Participant@roberthurst1Posted by not done it yet on 12/01/2019 19:34:31:Posted by Robert Hurst 1 on 12/01/2019 07:33:32:

Hi Peter, by generic I guess you mean the units manufactured by Huanyang amongst others.

These offer very good value for money, however the electronics is a bit marginal so I'd recommend buying a unit rated twice that of the motor, especially if running from a single phase supply.

Beware of vendors claiming that their unit will step up from 230 V to 415 V, this is simply not true. Check your motor can be re-configured for 230 V (delta or mesh connection). A 415 V motor will run on 230 V but will lack torque.

Cheers.

Sorry but not true and possibly misleading. One should not necessarily double the inverter power over that of the motor. Overload conditions may burn out the motor and then the VFD!

The clear suggestion that inverters cannot supply 415V outputs is tosh. I ran my lathe on a 415V inverter, simply because I was told the star point could not be split to enable delta connection. They DO. But the inverter was rather more expensive than a 230V equivalent.

Most, or all, good manufacturers offer both output voltages in the usual range. Just don’t expect an inverter marked as 230V three phase output to work at full power, if connected to a 415V star wired motor. Power will be down by about 40%.

Getting the correct inverter for the application is important.

I have five inverters running off single phse supply. Only one supplies 415V. It is the one marked 415V output.

Ok, let me expand a little on my original comments.

Firstly to put things into context I was formerly employed by a UK manufacturer of inverter based GPU's and UPS's so I do have a clear understanding of how the electronics work. I have also installed and commissioned VFD's up to 200kW from a number of manufacturers so aware of application and limitations.

"These offer very good value for money, however the electronics is a bit marginal so I'd recommend buying a unit rated twice that of the motor, especially if running from a single phase supply"

"Sorry but not true and possibly misleading. One should not necessarily double the inverter power over that of the motor. Overload conditions may burn out the motor and then the VFD!"

The Huanyang inverters, whilst very good are built to a price. As a rule of thumb in electronics, for every 10*c increase in temperature you half the lifespan, or put the other way if you can decrease the temperature by 10*c you double the lifespan. They are designed to be run from a 3 phase supply, giving 6 charging pulses per cycle from the rectifier. They can be run from a single phase supply, but this will give only 2 charging pulses per cycle, increasing the ripple current accordingly. This will increase self heating of the reservoir capacitors and reduce lifespan.

Please see; https://www.precision-elec.com/derate-three-phase-vfd-for-single-phase-power/

You should be able to enter the full load current of the motor when setting up the parameters. An overload condition should never endanger the motor or the inverter, but instead reduce torque (current) by reducing the speed (frequency) or shut the unit down.

"Beware of vendors claiming that their unit will step up from 230 V to 415 V, this is simply not true."

"The clear suggestion that inverters cannot supply 415V outputs is tosh. I ran my lathe on a 415V inverter, simply because I was told the star point could not be split to enable delta connection. They DO. But the inverter was rather more expensive than a 230V equivalent.

Most, or all, good manufacturers offer both output voltages in the usual range. Just don’t expect an inverter marked as 230V three phase output to work at full power, if connected to a 415V star wired motor. Power will be down by about 40%."

A VFD works by rectifying the incoming supply to a value roughly equivalent to the peak voltage of the supply, in the case of 230V~ this is around 350V dc, 400V~ around 560V dc. This is referred to as the bus or link voltage. The output stage then converts this back to AC, but the peak output voltage cannot exceed the bus voltage, ie the output (ac) voltage cannot exceed the input (ac) voltage.

My milling machine is fitted with a pole changing motor, so had no choice but to run at 400V. I have a step up transformer supplying a VFD at 400V single phase to achieve this.

Please see; https://inverterdrive.com/HowTo/240V-Supply-to-a-400V-AC-Motor/

There may be inverters on the market with a voltage doubler rectifier which could potentially supply an output greater than the input, but I'm not aware of any. I would have thought suppliers of VFD would push these if they were available, as it's an ever increasing application.

If you know of such, perhaps you'd care to cite a link or provide evidence. Can you back up your comments with some photos of voltage readings whilst in operation? Resorting to rudeness merely weakens your argument.

I've spent some time earlier looking on ebay at some of the entry level offerings, there certainly is a bewildering range and can see that someone unfamiliar with VFD's could be easily misled.

Regards.

13 January 2019 at 14:33 #390867SillyOldDuffer

Moderator@sillyolddufferPosted by Robert Hurst 1 on 13/01/2019 13:35:19:Posted by not done it yet on 12/01/2019 19:34:31:Posted by Robert Hurst 1 on 12/01/2019 07:33:32:

…

…

…

Firstly to put things into context I was formerly employed by a UK manufacturer of inverter based GPU's and UPS's so I do have a clear understanding of how the electronics work.

…

"Beware of vendors claiming that their unit will step up from 230 V to 415 V, this is simply not true."

…

A VFD works by rectifying the incoming supply to a value roughly equivalent to the peak voltage of the supply, in the case of 230V~ this is around 350V dc, 400V~ around 560V dc. This is referred to as the bus or link voltage. The output stage then converts this back to AC, but the peak output voltage cannot exceed the bus voltage, ie the output (ac) voltage cannot exceed the input (ac) voltage.

…

There may be inverters on the market with a voltage doubler rectifier which could potentially supply an output greater than the input, but I'm not aware of any.

…

Regards.

I'm with NDIY on this one Robert, and wonder if you're aware there's been revolutionary change in power supplies?

Back in the day, power supplies were based on heavy passive components and rather limited in what was possible at reasonable cost. For example a transformer taking a few kilowatts of 230V up to 430Vac at 50Hz is a hefty and expensive lump of metal, if you have to ask you can't afford it.

Switch mode operation opens up many possibilities beyond the simple technology you describe. They operate as follows:

- AC mains is rectified and crudely smoothed to about 300Vdc. The amount of current available is limited only by the size of the rectifiers and the mains fuse. It's feasible to get 3kW of DC from an ordinary domestic socket for a few pounds.

- A small oscillator runs on the board at high frequency, say 100kHz. This is used to drive a semiconductor switch that chops the 300Vdc into a square wave. Because the switch is either fully on or fully off it is extremely efficient.

- The square wave is transformed to whatever voltage is needed, up or down. The clever bit is that a transformer running at 100kHz is not only more efficient compared with what's needed to do the same job at 50Hz, it's tiny and dirt cheap. The toroid transformer in a 500W computer supply is about an inch in diameter.

Most switch mode power supplies transform voltage down. But there's no fundamental reason why they can't go up. What makes it less popular is the components have to be rated to take the extra voltage, which makes the VFD more expensive. But high voltage technology isn't new or exciting – in the good old days most radios used vacuum valves – the CRT in an ordinary TV would have 30kV on it. Homes were full of high voltage components.

Though exotic and expensive step-up VFDs have been about for a long time, what's new is that they're becoming hobby affordable. Previously it paid to convert the motor star/delta to run at lower volts and that wasn't always possible. Now there's a choice.

Dave

Edited By SillyOldDuffer on 13/01/2019 14:34:27

13 January 2019 at 15:05 #390868Robert Hurst 1

Participant@roberthurst1Ok, thanks Dave that all sounds feasible and makes perfect sense.

Yes, aware of SMPS technology, wasn't aware it was now being used in VFD's.

Do you have a link to such a device, as interested to learn more?

Many thanks.

13 January 2019 at 16:32 #390878john fletcher 1

Participant@johnfletcher1Peter F, have a look in your inbox I sent you a PM last week re inverters. Seems to be a lot of theory here, I thought what Peter wanted was to hear from some model engineers who have practical experience of what to buy. I'm not sure regarding dismissing those inverters made in China, most Model Engineers just want to be able to power up a three phase motor without all the trimming which Industry might require. Also, I think a lot of apparatuses, component,, tools etc parts with British and European sounding names are actually made PRC, think of VW and Landrover. John

13 January 2019 at 21:46 #390933Anonymous

Hmmm, my Yaskawa J1000 inverter bought to drive my Pultra instrument lathe is 240VAC single phase in only, not running on two imputs of three phase. And it was made in Japan not China.

There's no reason why a single phase input VFD can't output 415VAC, it just needs more electronics, although offhand I can't find one advertised. The smaller VFDs just have a rectifier on the input to create the DC bus. Which is why the manuals state they don't meet the EU standards for harmonic distortion without an external filter. However it would be possible to have power factor correction on the input, which is simply a switch mode power supply with a control loop that keeps the input current draw in phase and proportional with the input voltage. The PFC is essentially a boost converter so it could easily be set up to produce a DC bus voltage high enough to produce 415VAC from a single phase input.

The output stage of a VFD looks like this, with IGBTs:

where U, V and W are motor connections. The half bridge drive signals are a bit more complicated than a square wave. Each half bridge produces a PWM signal swinging between 0V and the DC bus. The PWM changes on a cycle by cycle basis so that a filtered version of the PWM would produce a sine wave. In general IGBTs are prefered to MOSFETs in VFD applications.

A while back I wrote some notes on operating and driving IGBTs but deleted them in a huff after being told by a forum member that I didn't know anything about the fast Fourier transform. Which was a bit odd as part of my Ph.D was concerned with ways of computing it in hardware in real time with 100MHz bandwidth signals. If anyone is interested I can reinstate them.

To elaborate on the switchmode notes provided by SoD most of the small off the shelf DC-DC converters do indeed contain a transformer, as this gives the useful feature of an isolated output voltage. However, most small switchers do not use a transformer. There are a myraid of topologies but for low power, say <100W, there are four basic types.

1. Buck converter – converts to a lower voltage than the input, essentially a switch producing a PWM signal and followed by an inductor/capacitor low pass filter.

2. Boost converter – converts to a higher voltage than the input, essentially using the flyback voltage from an inductor to boost the voltage

3. SEPIC – can convert to a voltage both below and above the input – stands for single-ended primary-inductor converter. This uses two inductors in the switching. Oddly both inductors have the same voltage impressed on them, so the currents are the same, and they can be placed on a single core. But to be clear the dual winding is not a transformer

4. Flyback – which does use a sort of transformer although not in the conventional sense – it can produce just about any output voltage depending upon the turns ratio of the primary and secondary windings.

Frequencies are getting higher, many of the low power ICs can switch at low megahertz, so the inductors can be tiny. There are of course many more topologies especially as one gets to higher powers where transformers are driven by full bridges with phase control.

Way back when one designed a switch mode power supply you were lucky to get a basic control IC to which you needed to add a significant number of key components. With the advances due to mobile phones and laptops there are now hundreds of ICs available with some high quality simulation and design packages available for free from the manufacturers. There are also a range of nifty topologies such as buck-boost converters, boost converters that can disconnect the output and flyback designs that sense the impressed secondary voltage on the primary during the off time so you don't need to design an isolated feedback voltage circuit, yippee!

If that hasn't bored the pants off everyone nothing will! A final note; I always used to prototype switch mode converters because they never quite did what it said on the packet. But the newer ICs are very good, with good application software and notes so one can be confident of designing and going straight to PCB without getting egg on face.

Andrew

13 January 2019 at 22:27 #390934Paul Kemp

Participant@paulkemp46892Posted by john fletcher 1 on 13/01/2019 16:32:05:Peter F, have a look in your inbox I sent you a PM last week re inverters. Seems to be a lot of theory here, I thought what Peter wanted was to hear from some model engineers who have practical experience of what to buy. I'm not sure regarding dismissing those inverters made in China, most Model Engineers just want to be able to power up a three phase motor without all the trimming which Industry might require. Also, I think a lot of apparatuses, component,, tools etc parts with British and European sounding names are actually made PRC, think of VW and Landrover. John

Well I am with John on this. My electrical tuition was about 40 years ago, never really sunk in, never really had any interest in it! Consequently I have a base underpinning knowledge of electronics which gets me by but no real ambition to expand or develop it. All I wanted when I got my mill that has 3 phase motors is to get it running from a single phase 240v supply. I bought a couple of the Chinese Huangthingamyjig inverters from e Amazon for less than £90 ea. Connected them up, switched on and for a year they have been doing exactly what it says on the tin (having written this they will probably go bang!). Programming them was a bit of fun but plenty of resources on YouTube and regarding the pot range on the speed control some great feedback on here. They were the means to an end – getting the machine running and cutting metal, nothing more than that! I am very happy with them as they have done exactly what I want. Yes I could have gone more expensive (between 2x and 3x the price I paid) for European versions, yes they may be better built with better quality gizmo's and with greater programming flexibility and more functions and they probably would last longer and have more local support / warranty and possibly repair options. Mean time however I have an extra £200 – £400 in my pot for tooling, equipment and materials to push my project on. The VFD's were just another step towards a bigger project, not the project itself!

Paul.

13 January 2019 at 22:39 #390938John Haine

Participant@johnhaine32865FWIW, I have two inverters driving machines. One is an IMO which came from Transwave and is made in PRC – advantage is you get local support from Transwave who I found very responsive when I had a setup problem. The other is an Altivar that I bought some time back through another ME site. Made I think in Germany. Would recommend either make. I also have a Huanyang on a shelf, didn't come with a manual and impossible to download one that makes sense, so on the shelf it stays until needs must.

13 January 2019 at 23:35 #390943 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104Whatever the flavour or you power supply is it can be changed to suit your load, the cost of doing it it another matter. If you want to run a motor that is three phase and 230v between phases then happy days, a very affordable is inverter is available. If you want a 415v output then this adds a bit more complication which will cost more, As the late JS used to say things need to be fit for purse and inverters fall into this window. A three phase supply for the home workshop is usually more than most people want to pay for so we resort to inverters and converters. As the advantages of a VFD become desirable despite some features like torque loss at low frequency we fall in love with the technology but still want it as cheap as possible. Some people may shy away from the ready made packages but if you want a safe we’ll engineered installation then they are good value for money. Many home brewed installations would struggle to be considered safe by industrial standards and I doubt that many would meet any proper standards including my own dodgy setups. I know that I push my luck by scrimping on doing a proper job but being unaware that you are not meeting requirements can be dangerous and I think some members are in this position.

Mike

14 January 2019 at 00:05 #390949Pete Rimmer

Participant@peterimmer30576I have several VFD's – Omron, Vacon, Yaskawa, Weg. By far the easiest and most intuitive to set up is the WEG aided by the excellent manual. I just got the Yaskawa today and though it has a myriad of setup options which would make it very versatile the manual is not so intuitive to follow. The Vacon one was also quite clunky to program. Both the Yaskawa and the WEG have dc injection braking which is very handy.

Andrew – my V1000 is also single phase but retains the three incoming power terminals, terminals 2 and 3 being bridged.

14 January 2019 at 01:05 #390953 Pete.Participant@pete-2

Pete.Participant@pete-2Thanks for all the replies, I just noticed how many there were.

By 'generic' I meant the Chinese own brand names that pop up on ebay when you do a search, the ones for around £50 -£60,

More about the intended use, it's to wire up to a Boxford VM30 milling machine, from what I understand, VFD's don't like switches downstream, I want to retain the original on/off switch, coolant on/off switch and safety kick stop if possible, will I be able to wire these switches to the VFD to retain the use of these? and will the VFD power the drive motor and a separate coolant pump motor?

Cheers

14 January 2019 at 09:37 #390972RobCox

Participant@robcoxSounds like you want to do a similar thing that I did to my Elliot mill. In my case, I stripped out the spaghetti that was the original wiring, junked the original control switches and effectively started from scratch with the electrics.

I started with a pair of WEG inverters – 230V types. The motors are not reconfigurable to delta, so I used the tehcnique described in the inverterdrive.com link to set the parameters. One VFD drives the horiz/vert spindle motors (a 3 pole 2-way switch changes over the motor connected to the VFD but you can't change whilst it's running – but why would you!), the other drives the table feed motor. I located the VFDs, fuses and a NVR relay in a wall mounted enclosure with two umbilical conduits – one carries 3 phase to the motors and the other carries all the control wires to the control box. I relocated the controls (the original controls were at knee-height which brings your face closer to the "action" when turning on/off). I had two goes at the design of the control box before I was happy with it.

I chose the WEG inverters as the control inputs enabled me to control the motors as I wanted – start, stop, jog (rapid feed for table) fwd/rev and a speed control pot. I have a separate switch to disable everything at knee height for safety/emergency.

For the coolant pump, which works but I haven't used it yet in anger, I used a Steinmetz capacitor to provide the 3rd phase. Cheaper than a VFD and you don't need the variable speed on the coolant!

Some pictures for reference:

Rob

14 January 2019 at 23:35 #391097 Pete.Participant@pete-2

Pete.Participant@pete-2Hi Rob, thanks for the reply, looks like you've done a tidy job of that, it got me thinking if it might be simpler/cheaper to just replace the motor with a single phase, as I don't need to control the motor speed in any way, but out of interest (please excuse my electrical ignorance) could I use a single VFD to power the main motor and the pump motor?

15 January 2019 at 08:54 #391119RobCox

Participant@robcoxHi Peter, If you run two motors on one VFD you'll probably have to start and stop them at the same time. VFDs don't like switched loads downstream.

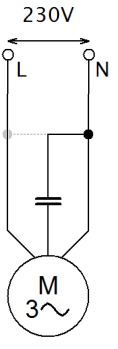

The coolant pump is probably <100W – mine is – and all you need to get that to spin is a capacitor and a double pole switch. The connection is as follows:

The capacitor value I used was 8uF, 440Vac. I used a motor run capacitor from RS, which will only cost you a fiver plus the switch. My pump motor has 440V star connected windings with no provision for configuring to delta, but it still runs just fine on 240V.

This will enable you to optimize the VFD settings for the main motor (startup, run-down time). I wouldn't be without the variable speed – it saves a lot of belt changing – and if you have chatter you can drop the speed quickly without having to stop a cut, so I'd stick with the 3-phase motor and a VFD rather than go single phase.

16 January 2019 at 17:20 #391408 Pete.Participant@pete-2

Pete.Participant@pete-2Hi Rob, I think I'll try one of those cheap VFD's as generally people on here seem to think they are ok, and will probably follow your advice for the pump motor.

The reason I mentioned a motor switch as an option is the Boxford VM30 machine has infinitely variable speed up to 3000rpm via expanding pulleys that are controlled from a dial on the front of the machine, so I only need the motor to run at a single speed.

But I should be able to wire a VFD up to the start and stop switch, and have it housed safely out of harms way inside the machine via the door on the back, I have seen pictures of someone do this, that should get me up and running, and would be the cheapest way to get it into action.

And when I get the time and inclination, I'll follow your advice on getting the pump motor into action,

Thank you for the taking the time to explain these things, and everyone else who has commented here offering advice.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Electronics in the Workshop › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Use horizontal mill as saw for metal?

Started by:

ell81 in: Beginners questions

- 16

- 17

-

9 April 2025 at 23:13

Dave Halford

Dave Halford

-

Steam pressure using thermistor

1

2

Started by:

michael howarth 1 in: General Questions

- 16

- 39

-

9 April 2025 at 22:59

duncan webster 1

-

Potential new society in North Yorkshire

Started by:

cliff almond 1 in: Model engineering club news

- 6

- 8

-

9 April 2025 at 22:49

Nigel Graham 2

-

N Devon Model Engineers, is this the end?

Started by:

Engine Builder in: Model engineering club news

- 10

- 12

-

9 April 2025 at 22:45

Nigel Graham 2

-

Motor bearings and more

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 3

- 3

-

9 April 2025 at 21:00

Macolm

-

Hello

Started by:

tbm in: Introduce Yourself – New members start here!

- 3

- 3

-

9 April 2025 at 20:07

noel shelley

-

Re-Visiting My Stuart Victoria

Started by:

Steve Withnell in: Work In Progress and completed items

- 1

- 1

-

9 April 2025 at 17:15

Steve Withnell

-

Good quality Jewellers screwdrivers.

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 8

- 12

-

9 April 2025 at 16:51

Robert Atkinson 2

Robert Atkinson 2

-

Small type Reilang oil gun

Started by:

john fletcher 1 in: General Questions

- 1

- 1

-

9 April 2025 at 16:49

john fletcher 1

-

Half Scale 1/4HP A J Weed Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 4

- 13

-

9 April 2025 at 16:45

JasonB

JasonB

-

Myford 254S Lead screw lever issue

Started by:

alan1b in: Help and Assistance! (Offered or Wanted)

- 3

- 3

-

9 April 2025 at 16:40

Dave Halford

Dave Halford

-

Building Bernard Tekippe’s Precision Regulator

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 3

- 4

-

9 April 2025 at 15:12

Chris Raynerd 2

-

DIY Pendulum Timer – GPS-Synced Beat Analyser

1

2

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 7

- 26

-

9 April 2025 at 14:01

Bazyle

Bazyle

-

DC Wasp Rebuild

Started by:

William Chitham in: I/C Engines

- 6

- 11

-

9 April 2025 at 09:40

petetwissell

petetwissell

-

24cc DIESEL ENGINE FROM SOLID

Started by:

dean clarke 2

in: I/C Engines

dean clarke 2

in: I/C Engines

- 9

- 18

-

9 April 2025 at 09:37

petetwissell

petetwissell

-

Autodesk Fusion Discount

Started by:

Alan Wood 4 in: CAD – Technical drawing & design

- 4

- 4

-

9 April 2025 at 09:32

John Hinkley

John Hinkley

-

Measuring increments on boring head

1

2

Started by:

Bill Phinn in: Workshop Techniques

- 16

- 33

-

9 April 2025 at 08:51

JasonB

JasonB

-

taper pins

Started by:

Garry Coles

in: General Questions

Garry Coles

in: General Questions

- 6

- 7

-

8 April 2025 at 21:19

Nimble

-

Myford Super 7 restoration problem.

Started by:

Bootlegger Blacky

in: Manual machine tools

Bootlegger Blacky

in: Manual machine tools

- 4

- 5

-

8 April 2025 at 20:39

Bootlegger Blacky

Bootlegger Blacky

-

Damp proofing concrete floors

Started by:

Duff Machinist in: General Questions

- 15

- 17

-

8 April 2025 at 15:56

Chris Crew

-

Contact Details for the family of Alan Barnes

Started by:

Neil Wyatt

in: General Questions

Neil Wyatt

in: General Questions

- 1

- 1

-

8 April 2025 at 14:05

Neil Wyatt

Neil Wyatt

-

Myford saddle lock issue

Started by:

Andrew Moyes 1 in: Manual machine tools

- 1

- 1

-

8 April 2025 at 13:16

Andrew Moyes 1

-

New member old lathe

Started by:

t1krt in: Introduce Yourself – New members start here!

- 8

- 17

-

8 April 2025 at 12:36

parovoz

-

Reader Survey

Started by:

Neil Wyatt

in: Model Engineer & Workshop

Neil Wyatt

in: Model Engineer & Workshop

- 14

- 24

-

8 April 2025 at 12:31

parovoz

-

Easing out the bore of a 3-jaw, s/c chuck

Started by:

Greensands in: Workshop Tools and Tooling

- 11

- 17

-

8 April 2025 at 11:39

Bazyle

Bazyle

-

Use horizontal mill as saw for metal?

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Use horizontal mill as saw for metal?

- Steam pressure using thermistor

- Potential new society in North Yorkshire

- N Devon Model Engineers, is this the end?

- Motor bearings and more

- Hello

- Re-Visiting My Stuart Victoria

- Good quality Jewellers screwdrivers.

- Small type Reilang oil gun

- Half Scale 1/4HP A J Weed Engine