Going back to the OP original question .

"I'd now like to move the table through minutes and seconds

( to be precise 19° 3' and 12". I can't work out how to do this.

Could someone please talk me

through it in a Pooh-Bear-of-Little-Brain-speak?"

I think there is little doubt from the many replies that there

would be a slim chance of obtaining an accurate position

of 19° 3' and 12" simply because of the mechanical errors

within the rotary table and also being able to count using

the existing hand wheel set up would be difficult to keep track of .

As has been mentioned before the stepper motor route would

be most likely to be able to count with some accuracy.

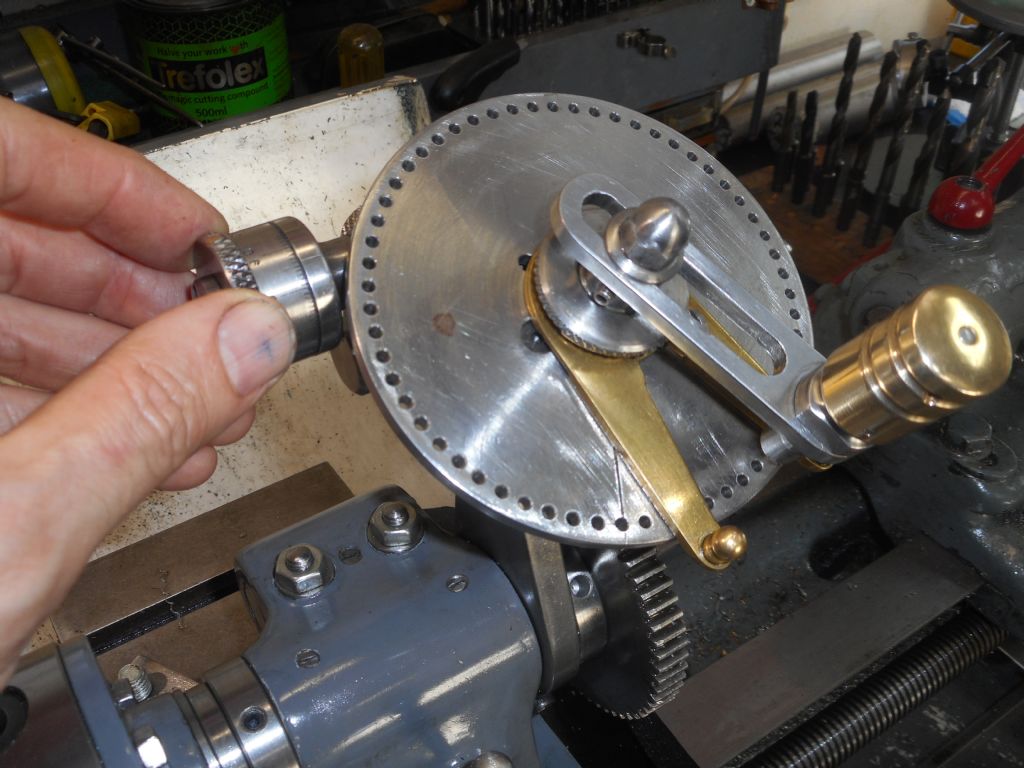

My own cnc rotary table has a worm and wheel ratio of 75 to 1

and connects to the stepper motor with a toothed belt ,as part

of some alterations which included regrinding the morse taper

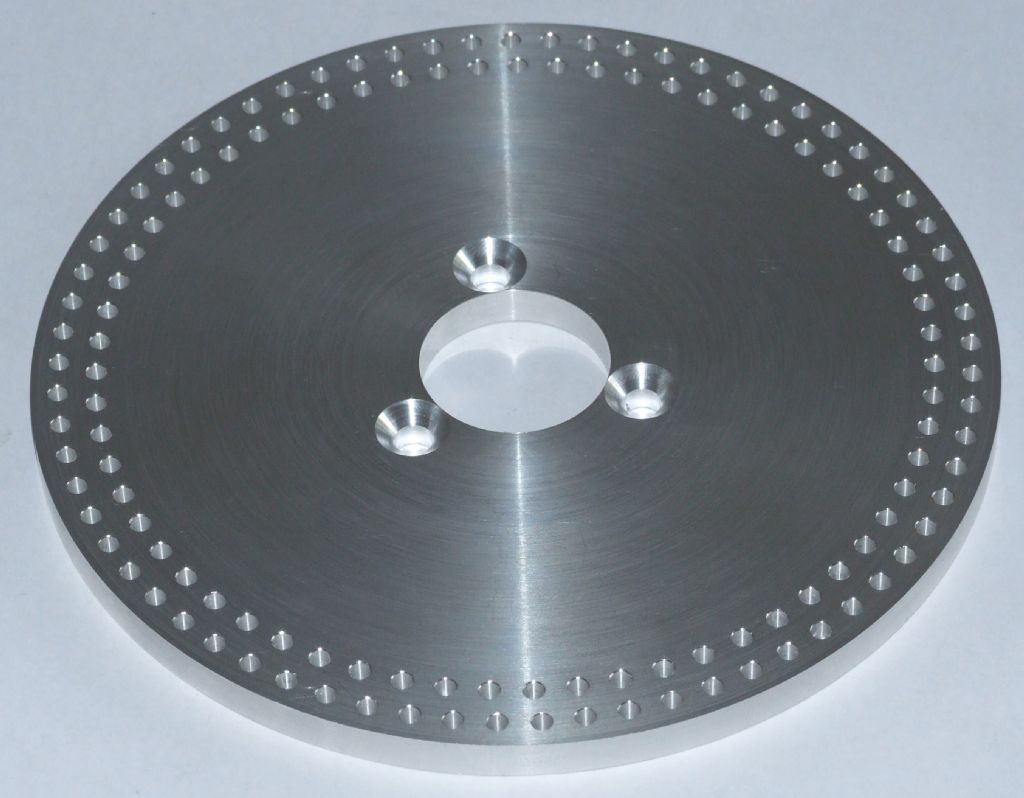

some additional drive pulleys have been made, these also

have some secondary functions on some other machines.

In doing this the rotary table can be between 75 to 1 ratio

and 142.5 to 1 with the pulleys that i have at this time.

Just playing around with numbers on this table using a 10 tooth

pulley on the stepper motor and a 72 tooth driving the worm

would make the table 540 to 1 ratio in whole step (200)would equal

108000 steps per rev .Since there are 1296000 seconds

in 360° divide by 12 to equal 108000,so a single step now

equals 12 seconds . 19° 3' 12" = 68592 seconds divide

by 12 for 5716 motor steps .

It is unlikely the rotary table will be accurate but at least

the count will be correct.

For a 90 to 1 table the 72 tooth pulley is changed to

60 tooth for the same count.

Probably too much work to set up if you don't already have

something like this already.

John

Howard Lewis.