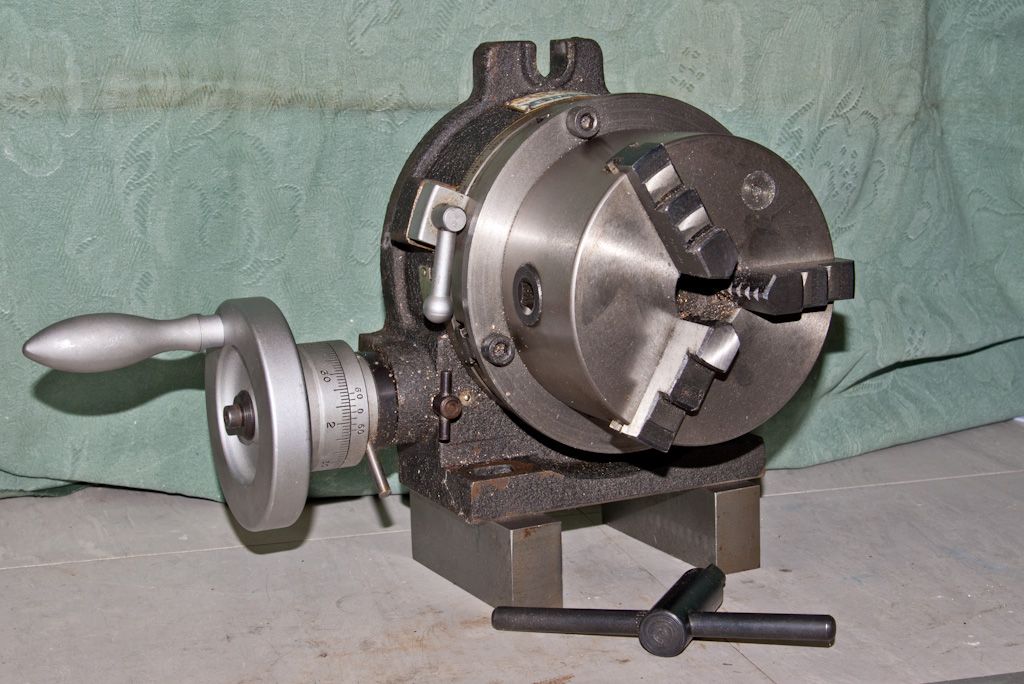

Yet another satisfied customer agreeing that Vertex made a good fist of the price / quality / performance balance. Mine is an 8″.

Couple of niggles tho’.

Firstly the hand wheel is large enough to overhang the bottom of the table when horizontal so you have to ensure that it overhangs the machine table or pack it up. Occasionally an issue for me when using it on my square column Chester Lux style mill where, as usual with these machines, the spindle axis covers little more than the inner half of the table Y travel. This also means you need to make a stepped base if you want to store it horizontal.

Secondly, and this applies to all the smaller rotary tables, there really isn’t room to use the conventional Tee nut, stud, clamp bar and step block / jacking bolt system. Even if the work is small the usual kits are too bulky so you need to get creative. Pity there is nothing more suitable off the shelf to get you going. When you do get creative remember that any Tee nut used purely to hold a stud should have a nut and washer holding it down onto the top of the table. Running the stud through and pushing up is unkind. I got hold of a small inch thick aluminium optical breadboard from Thor labs having a grid of 6 mm tapped holes at 25 mm spacing and bolted that to the table which was very effective for a lot of jobs and not silly expensive. Very tough anodised surface.

Even small tables are pretty heavy. For the 8″ I made a pull out shelf on ball bearing drawer runners. Far better than wrestling out of a drawer or cupboard as you have a clean vertical lift.

Having now scaled up and become a Bridgeport user the Vertex table is on the disposals “when I get round to it” list. The extra real estate of the 10″ and 12″ tables I now use makes life much easier.

Clive

Edited By Clive Foster on 13/12/2011 08:52:53

John McNamara.