Sorry for you: you will have to learn the simplest language on earth (at least for me): Dutch! May be, you have any native speaking Dutch around that might assist you?

I do not expect that there will be an English translation available. But, as you can see on the low-resolution drawing, the description is very limited. And there is at least one significant failure in the drawings I have.

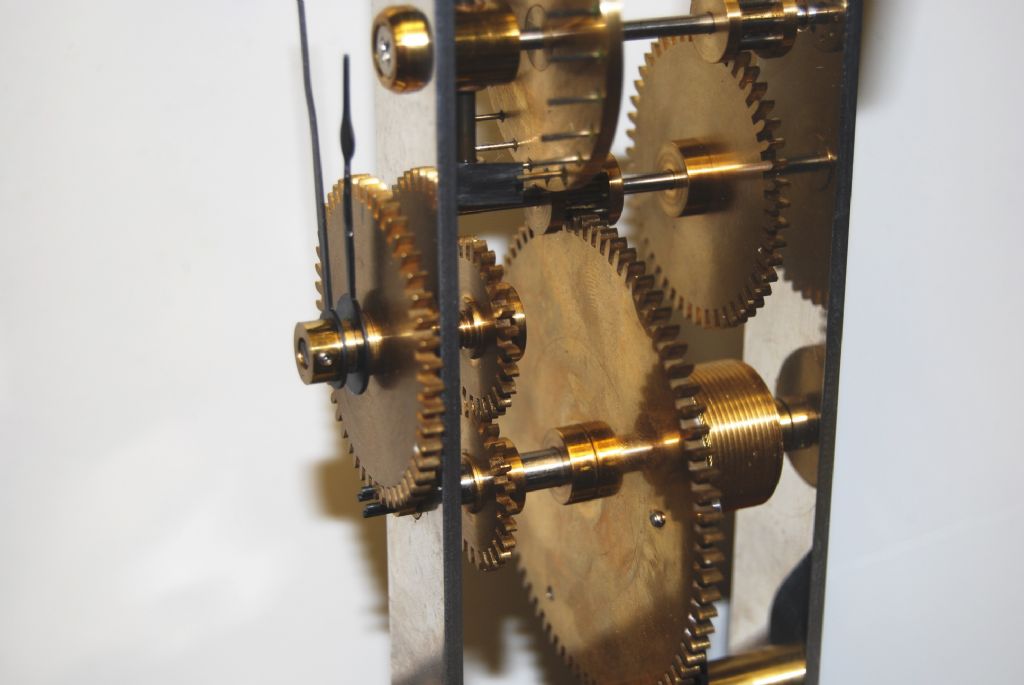

As I never made a clock before, there were several details and skills I had to “invent” myself. For instance: the most extensive description is for the 96 tooth wheel, and it only reads:

“Gearwheel 96T of brass. Copy shape of teeth from drawing. Cut-in with normal saw and shape wit small file. Teeth do not need to be exactly identical. Space between teeth somewhat wider than with of tooth.”

And the drawing of this item bears a note: “Glue on and saw”

I did not expect that it would make great fun to make the gearwheel (5 mm thick brass, 96 teeth) in this way.

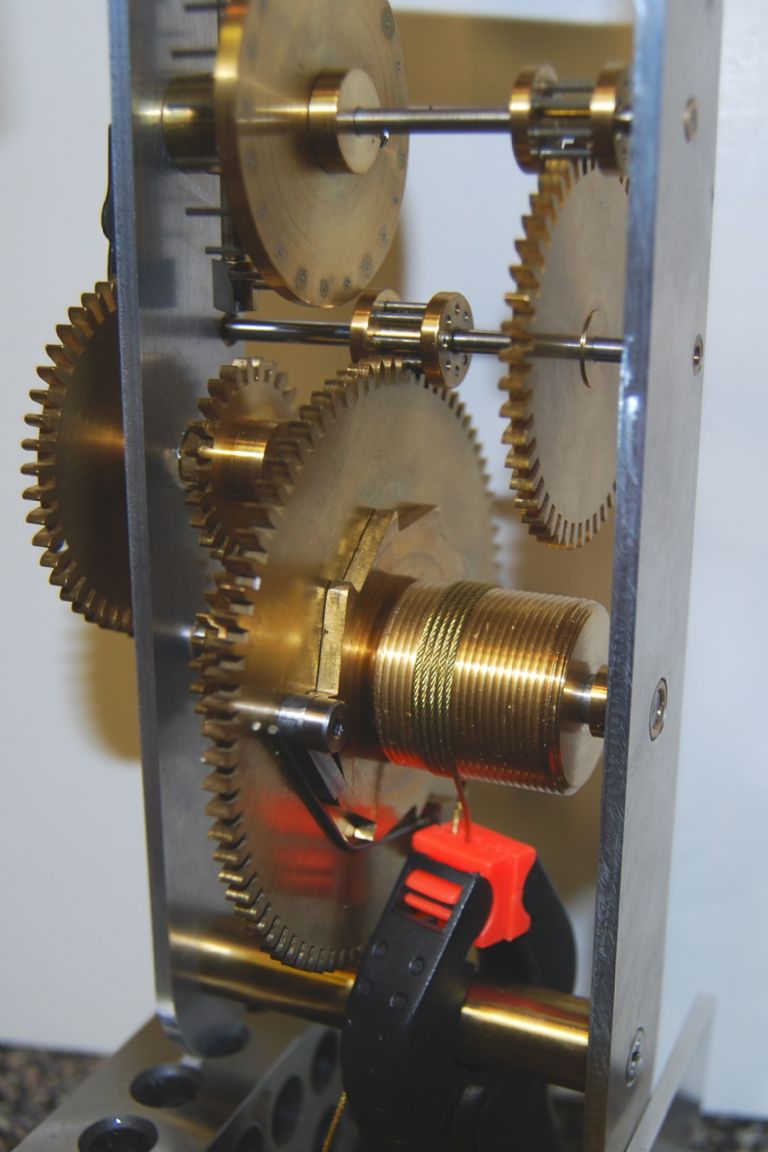

So I did it the vertical milling machine with a 1,5 mm slitting saw: one run with the slitting saw 5mm above centre and another run 5 mm below centre. And finally some filing.

I used my rotary table. But before starting gear cutting, I decided to first make a dividing set (dividing plate and arms)…….

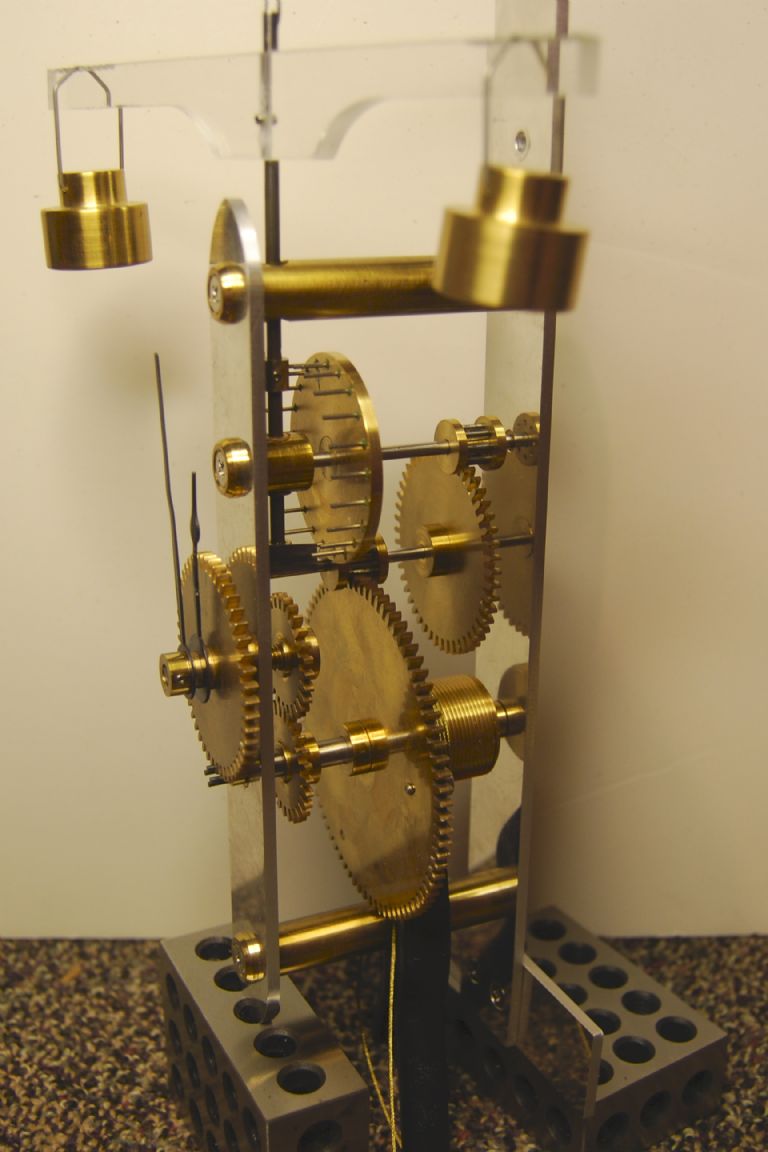

I think, it is indeed the simplest possible clock, so ideal for a beginner.

Last update:

The chain runs via pulleys now and I hope to start making the winding mechanism this evening. I will leave making the weights until the end.

Good luck!

And best regards from The Netherlands.

Gep

Edited By Gep Engler on 23/07/2009 16:36:43

Richard Parsons.

:

: