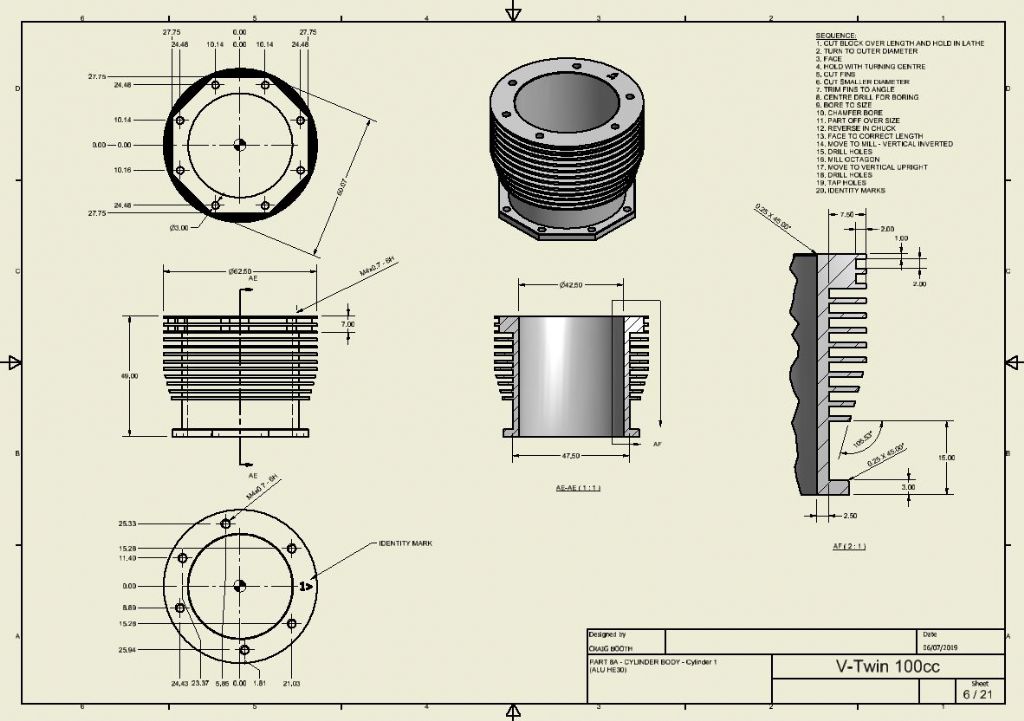

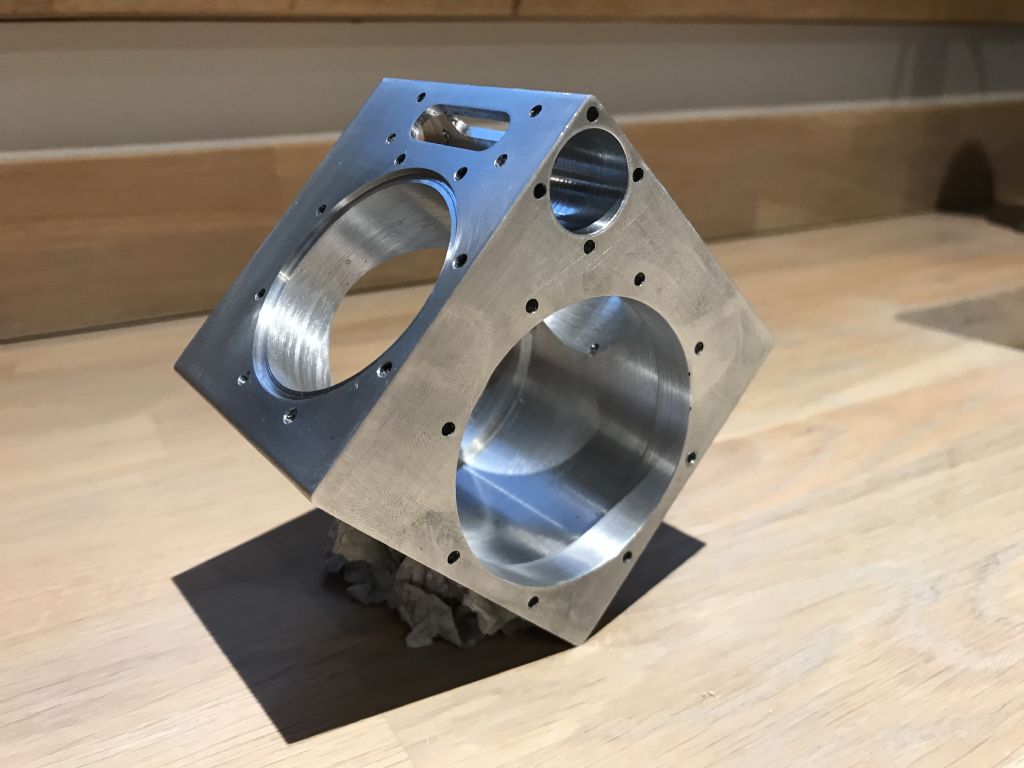

V-Twin 100cc Design & Build

V-Twin 100cc Design & Build

- This topic has 65 replies, 17 voices, and was last updated 16 January 2021 at 08:34 by

Craig Booth 1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Square end on round stock – Milling?

- I’m Under Pressure

- Sat nag

- Transwave converter – plugged in motor, tripped RCD

- motor and switch wiring Myford ML7

- Taylor Hobson cutter grinder modificaton

- Easiest/cheapest source of R8 socket

- Twin Engineering’s heavy mill/drill quill removal

- Bosch PBD 40 bearing upgrade

- Old plastic handled screwdrivers