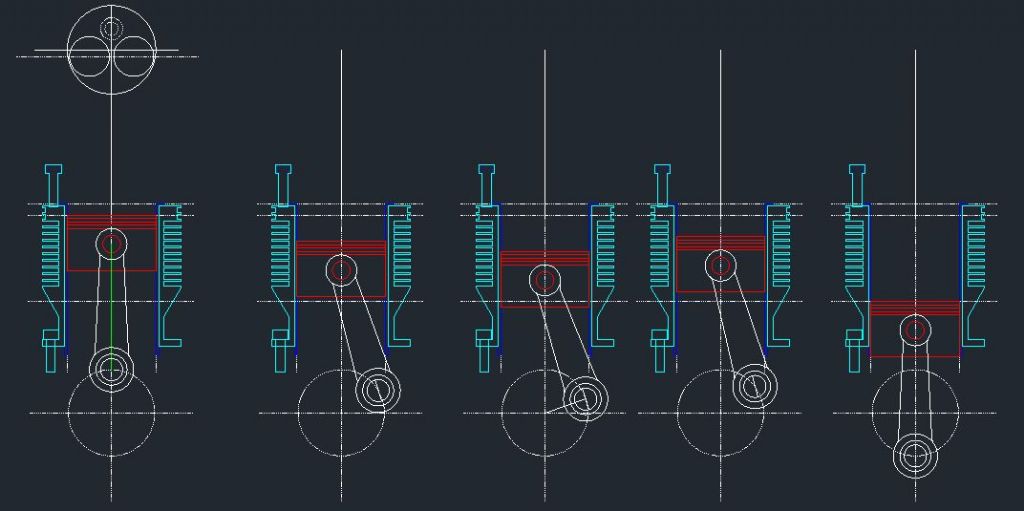

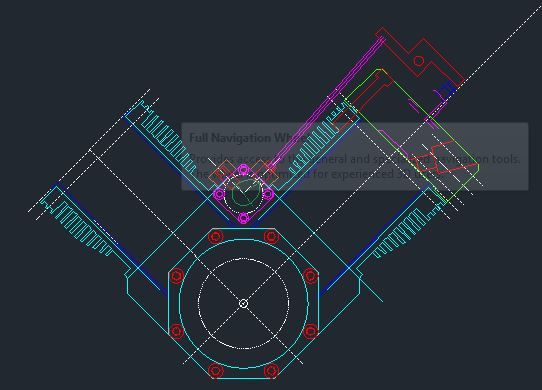

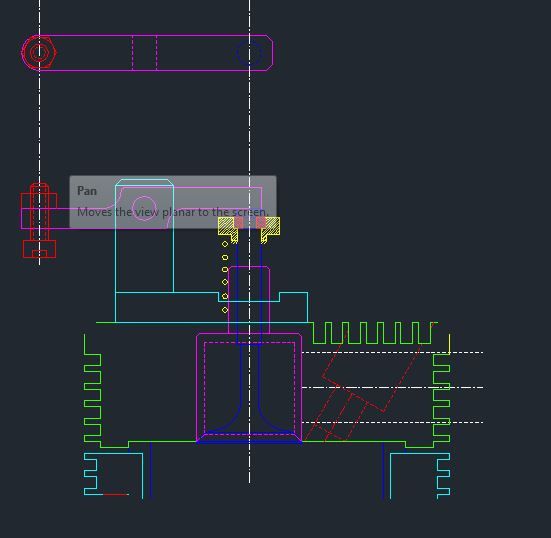

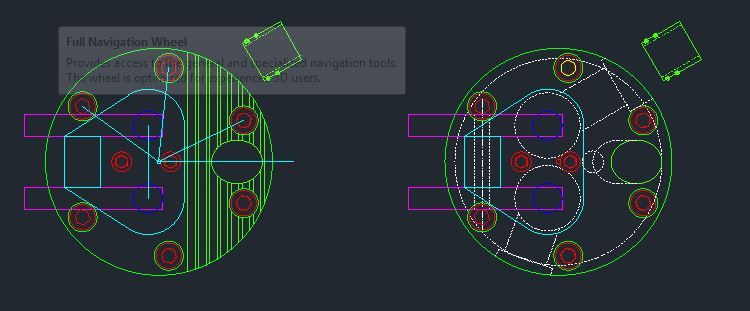

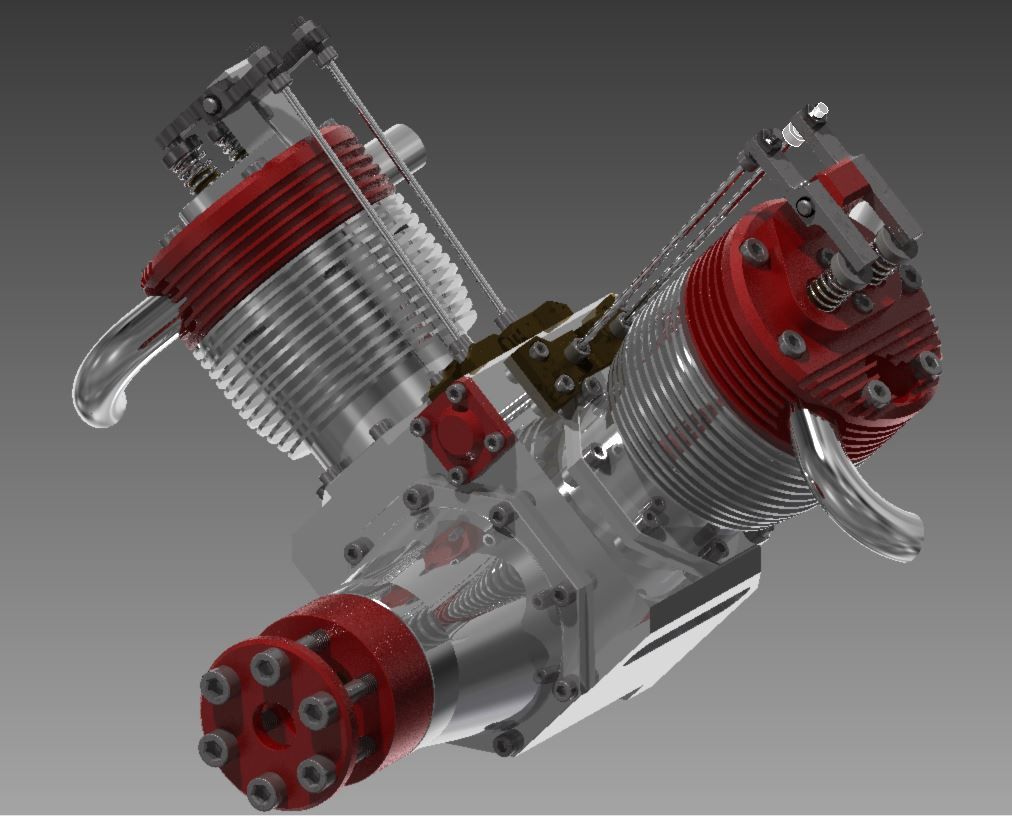

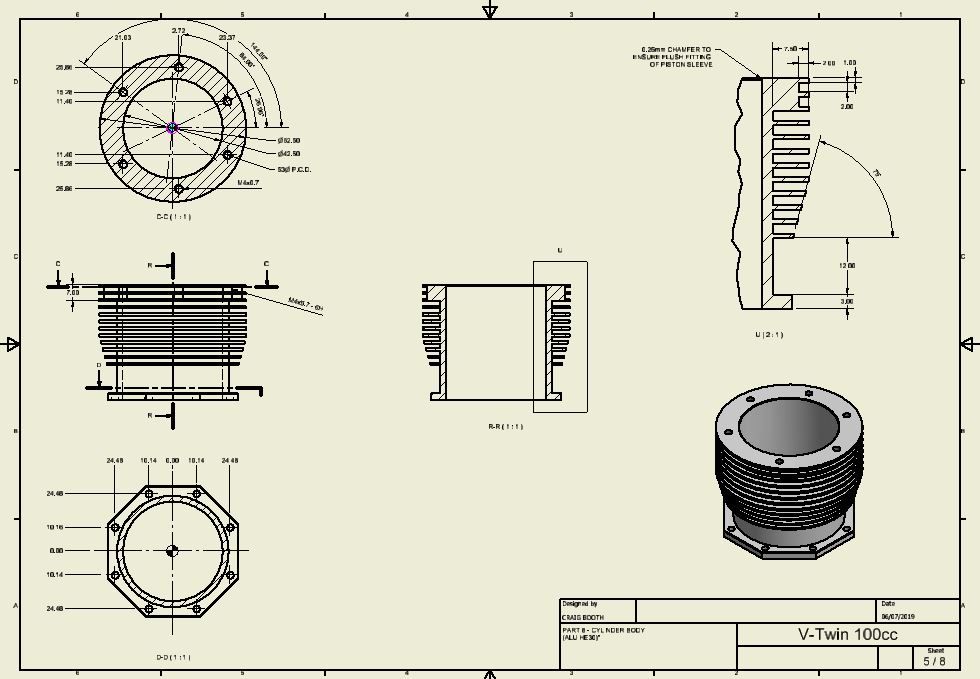

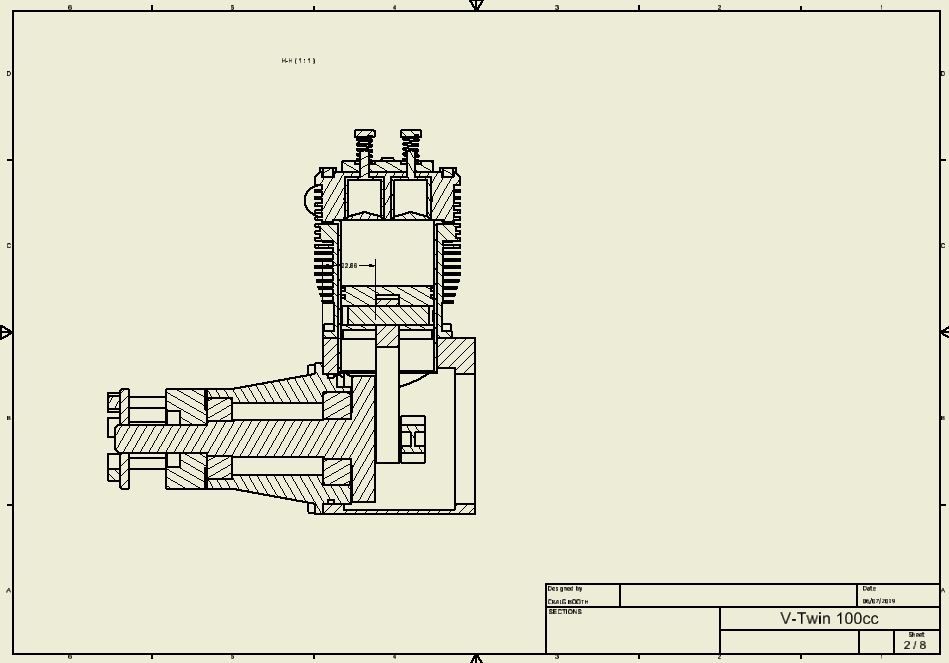

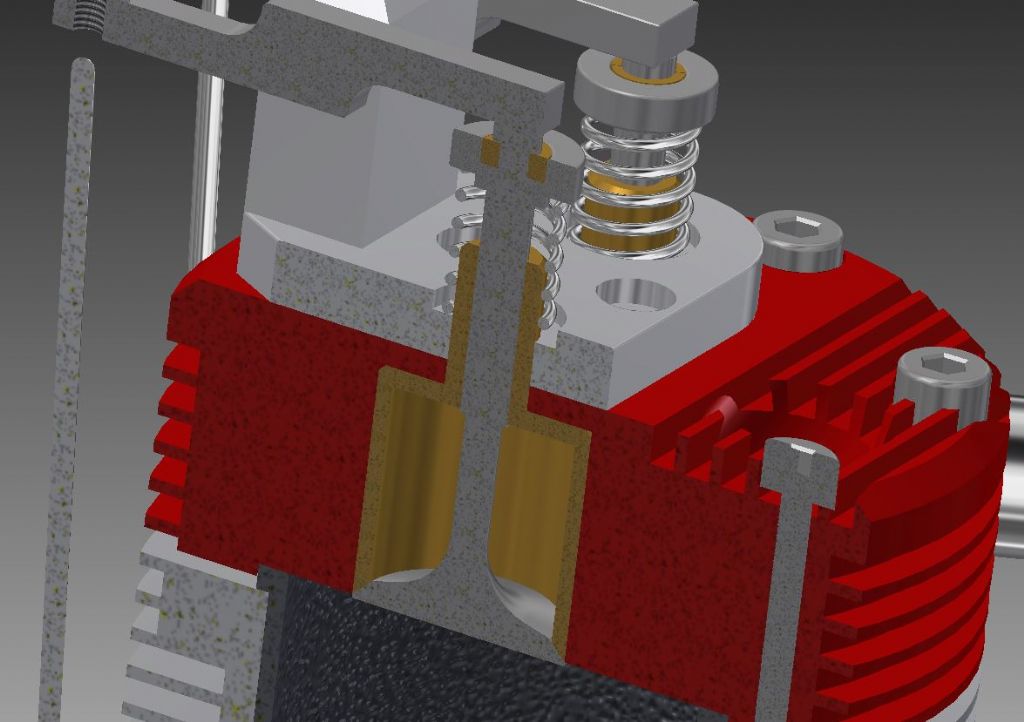

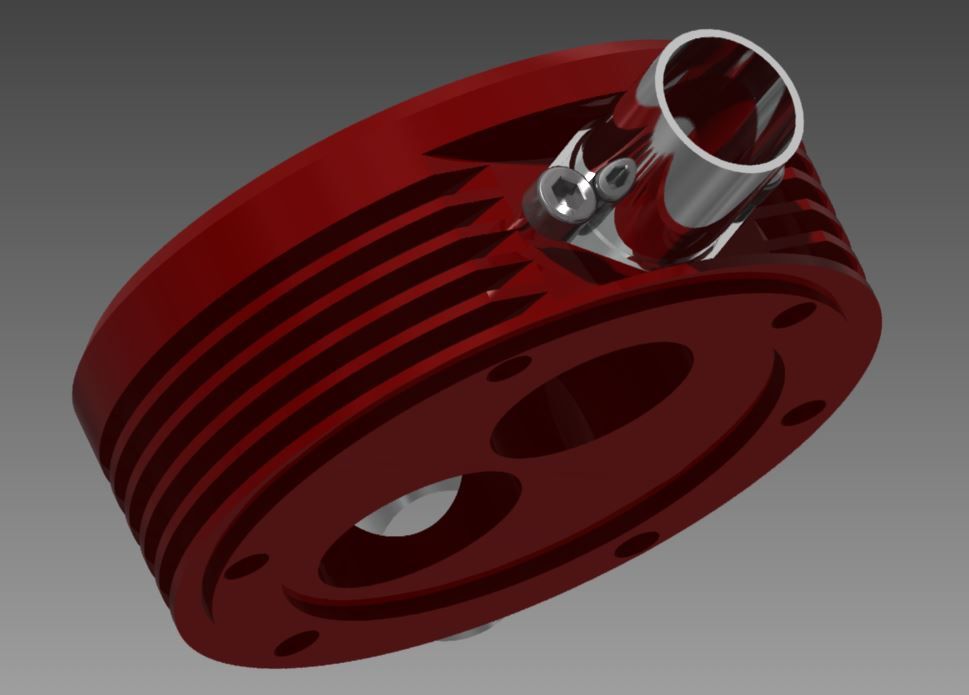

V-Twin 100cc Design & Build

V-Twin 100cc Design & Build

- This topic has 65 replies, 17 voices, and was last updated 16 January 2021 at 08:34 by

Craig Booth 1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Twin Engineering’s heavy mill/drill quill removal

- New member

- Starrett and other tool manufacturer wood boxes

- Pragotron Slave Clock

- M type top slide conversion??

- Boiler Design – issue 4765

- Colchester Chipmaster Clutch question

- Sanjay’s Banjo Engine

- In memoriam: Peter Neal

- Wickseed power hacksaw 8” information