Hi, this is my first post!

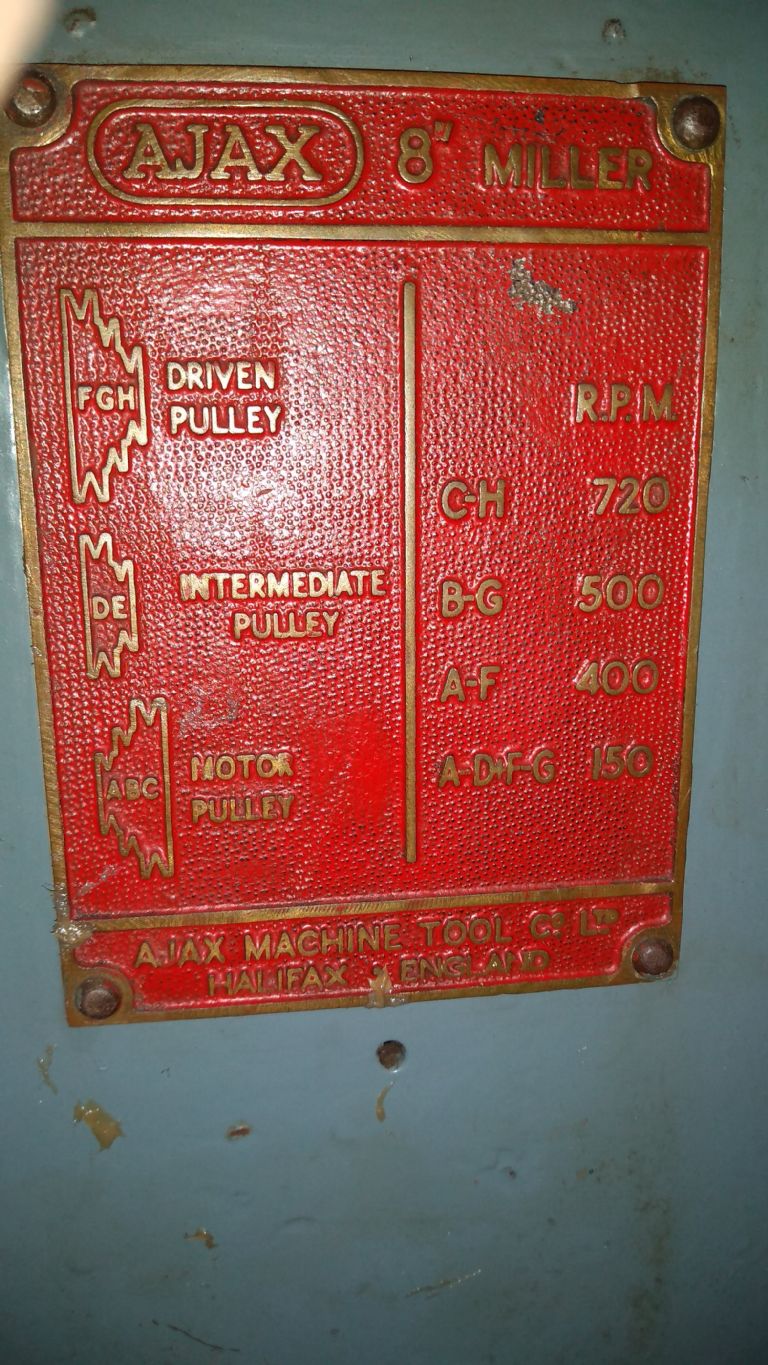

I recently purchased an old Ajax AJ8 horizontal milling machine in remarkably good condition for not a lot of money. I have since fitted a replacement motor and used the machine with good effect but there is a niggle with belt vibration. There is no vertical head, so everything is done on the horizontal spindle.

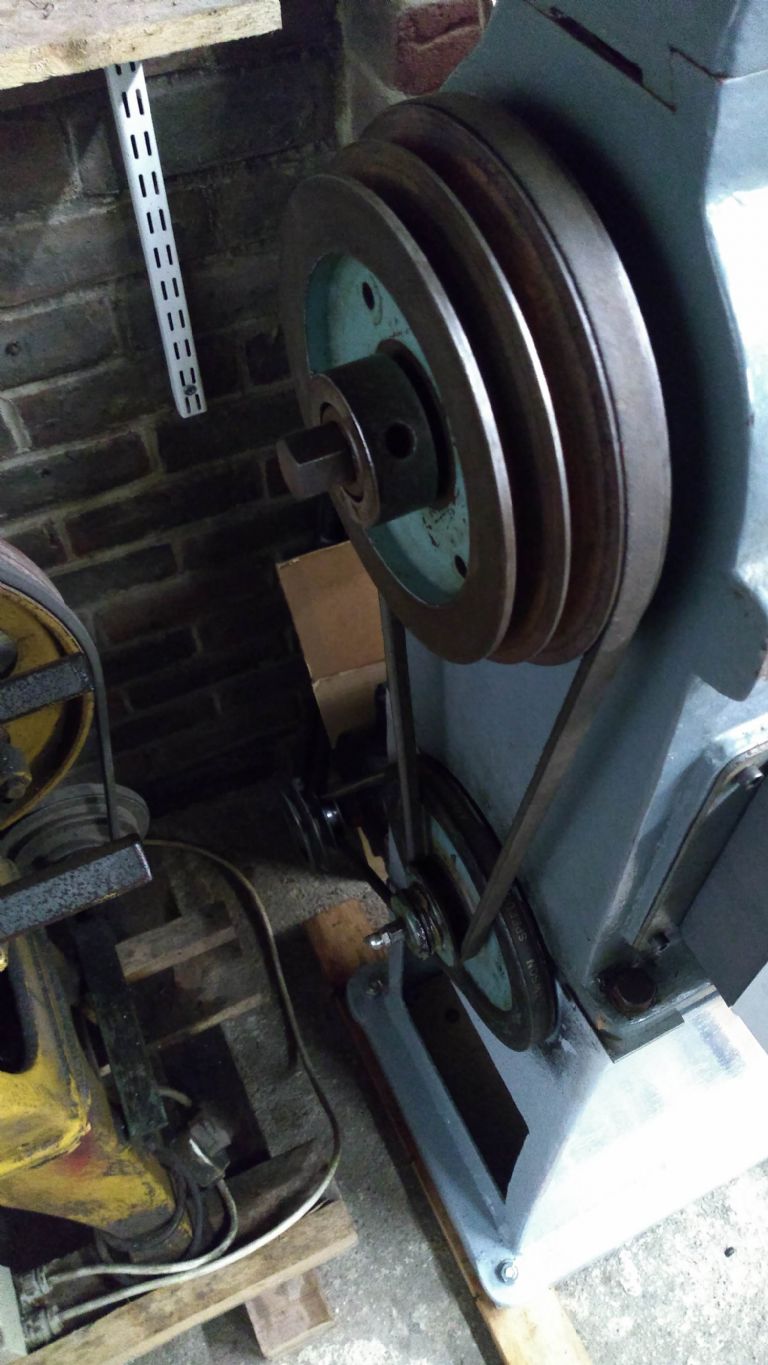

The machine has two v-belts, one from the motor to a 2-step pulley and the second belt to the main cutter spindle. Both belts are in my opinion correctly tensioned. All bearings are good, lubricated and tooling sharp.

When using a moderate size cutter (e.g. 5" x 1/2" I have noticed some vibration developing in the "slack" side of the final drive belt and this significantly adds to workshop noise. The whole machine is sufficiently heavy that the cut quality appears unaffected. I am mostly milling mild steel, with some cast iron.

I have noticed some vibration developing in the "slack" side of the final drive belt and this significantly adds to workshop noise. The whole machine is sufficiently heavy that the cut quality appears unaffected. I am mostly milling mild steel, with some cast iron.

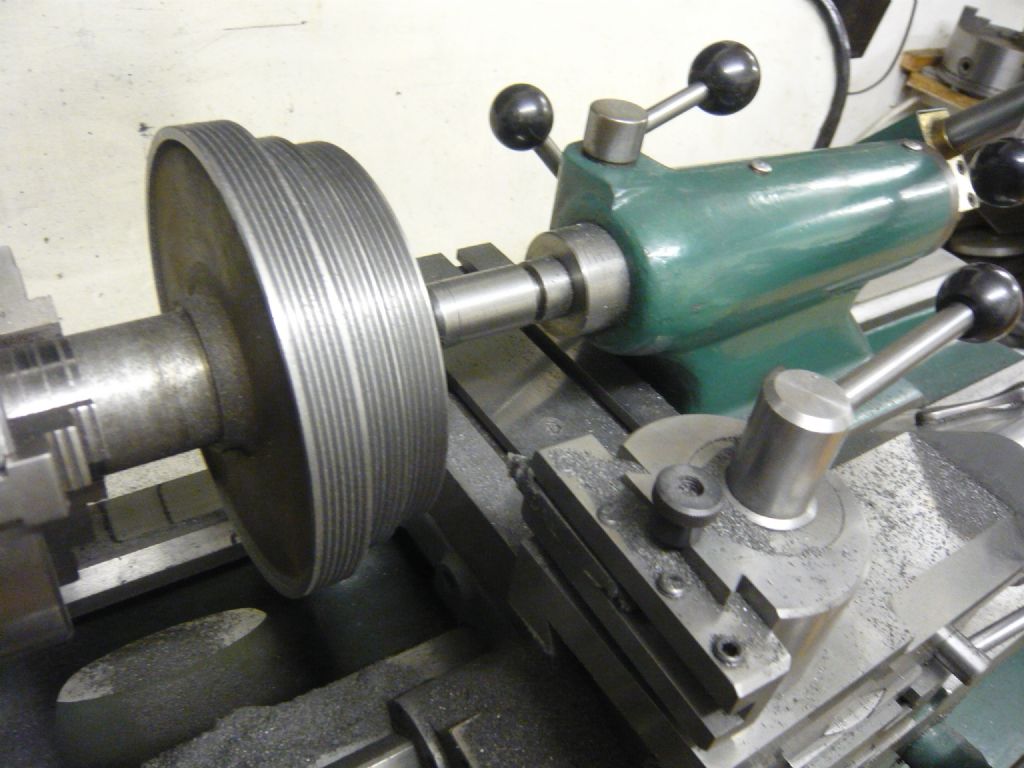

I have considered adding an idler pulley to the problem belt, thus shortening the distance between centres as I think this should eliminate the problem. However, before I attempt this fix I would welcome any other suggestions.

On a different but related matter, I need to make a chip tray for the machine and if anyone has the same miller I'd be interested to know what setup you use. I'd like to include a coolant pump and sump.

Brian

AJAX.

I have noticed some vibration developing in the "slack" side of the final drive belt and this significantly adds to workshop noise. The whole machine is sufficiently heavy that the cut quality appears unaffected. I am mostly milling mild steel, with some cast iron.

I have noticed some vibration developing in the "slack" side of the final drive belt and this significantly adds to workshop noise. The whole machine is sufficiently heavy that the cut quality appears unaffected. I am mostly milling mild steel, with some cast iron.