Hi Steve

As requested, here are a few photos of my DRO installation.

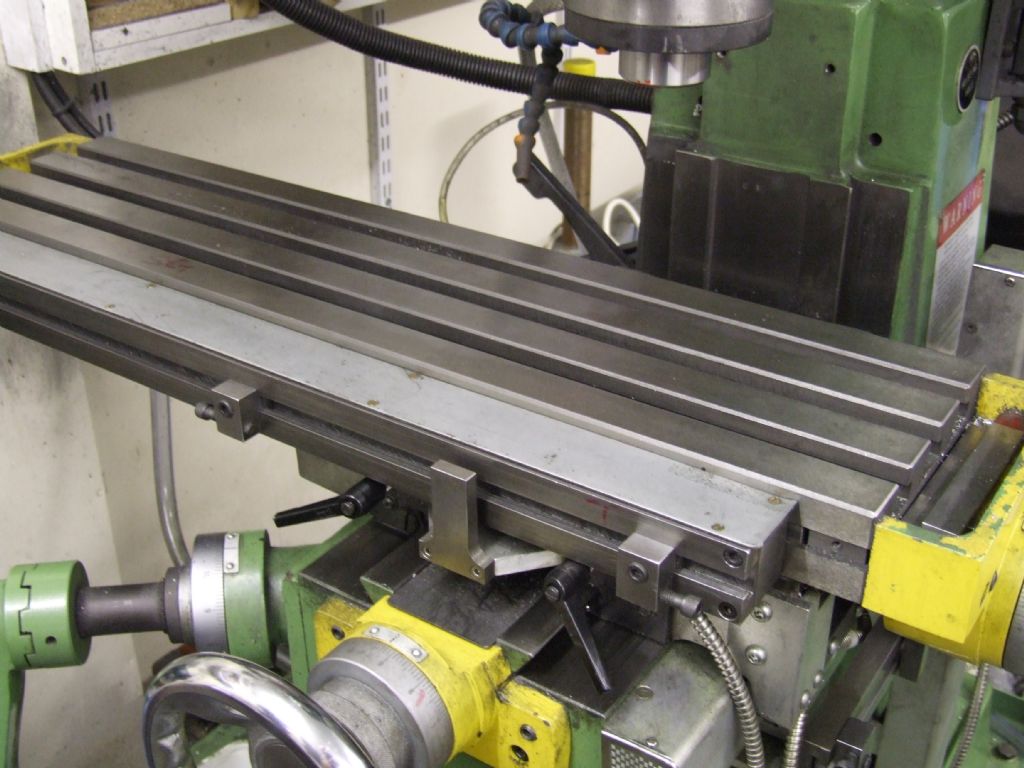

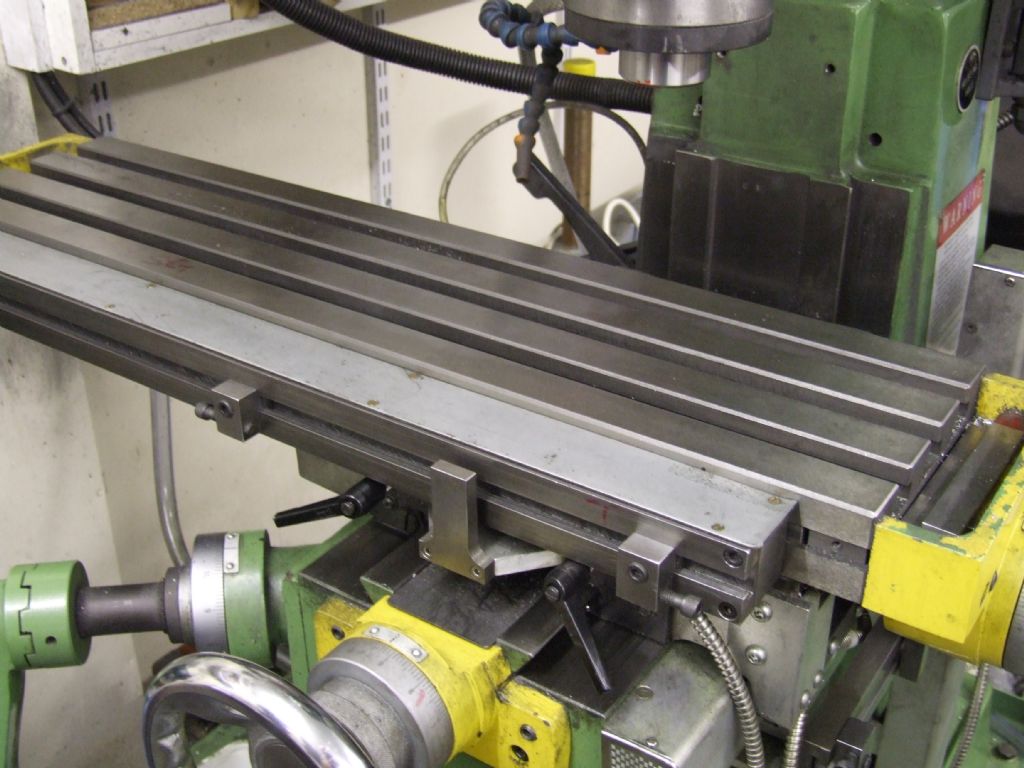

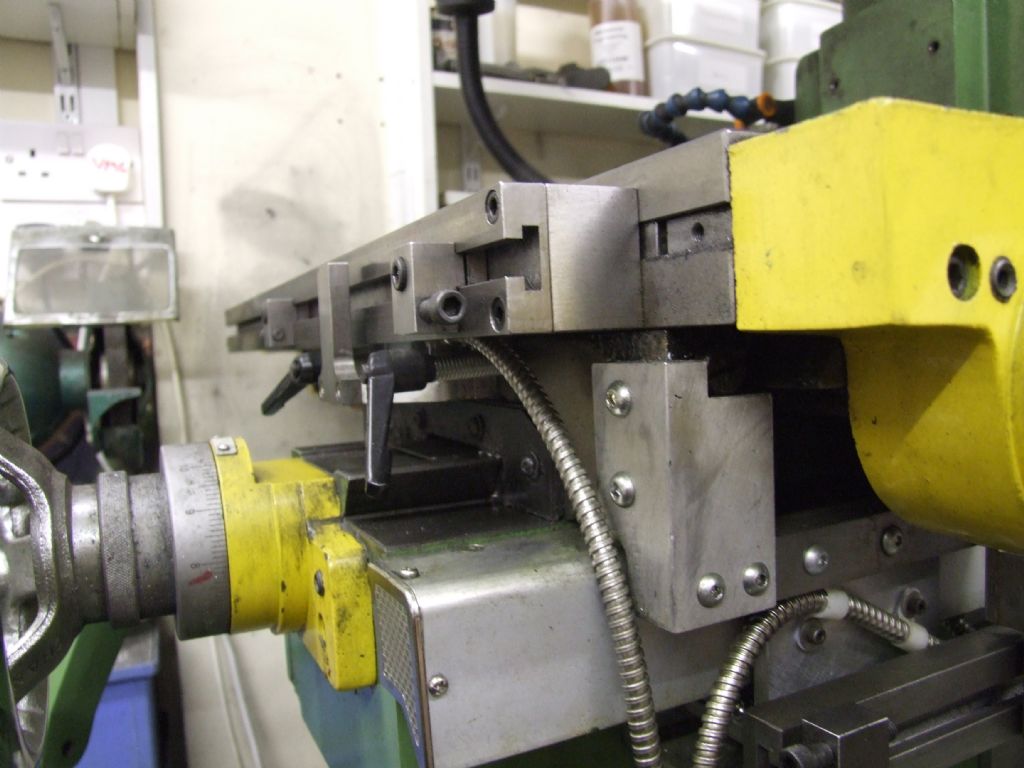

X-axis

The scale is attached into the existing stop ‘slot’ and then the new stop system is attached outboard of this, also into the existing slot. I made new dovetail nuts as those fitted to the machine were not very good and I also needed 2 more to attach the stop bar – the dovetail angle is 20 degrees inclusive and from memory are tapped M5.

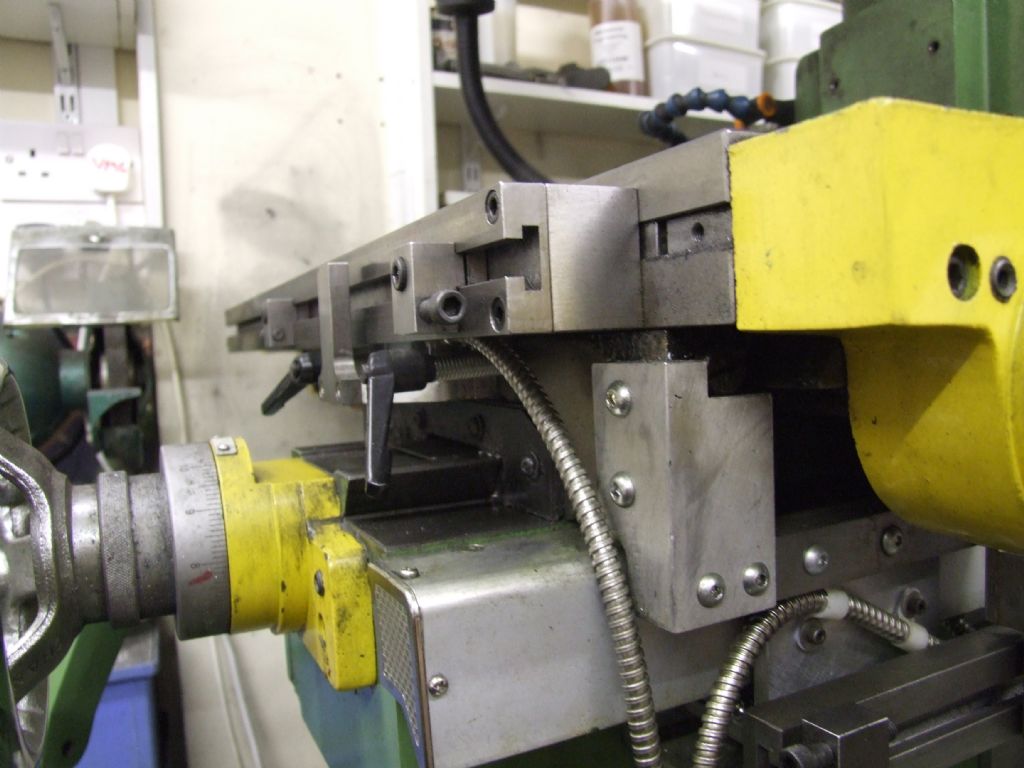

The stop bracket is basically ‘U’ shaped made from 3 pieces of alloy bar – one of the ‘uprights’ is screwed onto the machine saddle and the reader head is then screwed onto that – this gave the correct alignment of scale and reader head (after a little fine adjustment with the jacking screws). The stop itself is then attached to the horizontal member.

There was just sufficient space to attach the scale, reader head and stop bracket when using the slim scale – the standard scales would just be too large for this to be viable on the VMC.

I cut a T-slot in the new stop bar and made T-nuts as I found that the original dovetail nuts had ‘self-locking’ properties which would be irritating to use.

The installation was completed with the addition of a sheet metal cover to protect the scales.

The only problem that I’ve found with this installation is that the Z-axis feed handle hits the stop bar when the table is fully towards me and well to the left. This has not proved to be a serious problem.

As you can see from the photos it is still possible to fit table locking screws – I replaced the standard screws with adjustable handles. As for the electrical stops, I see no reason why these could not be retained if fitted with T-nuts and used on the new stop bar.

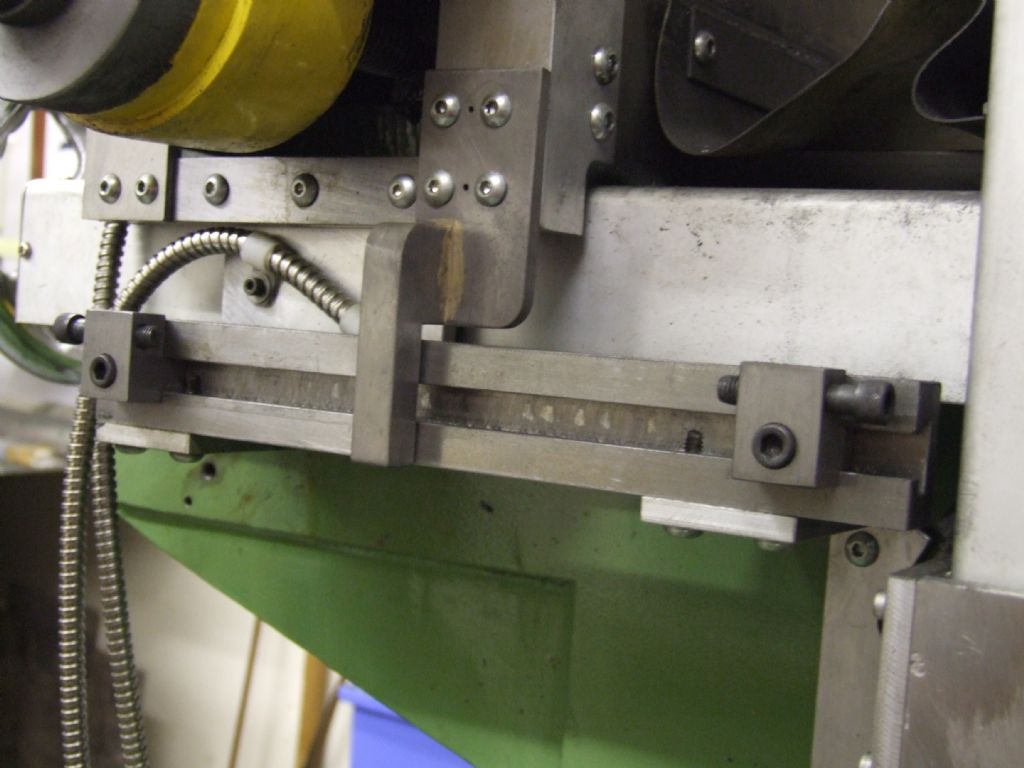

Y-axis

I employed a similar stop system to the X-axis. The scale was attached to the knee of the machine and the reader head was fitted to a bracket attached to the saddle. The stop bar was then fitted ‘outboard’ of this arrangement (on the knee), with the stop itself then fitted to the saddle of the machine.

No problems so far, but I suspect that you’re correct and it wouldn’t take much to damage the surface.

Note

This issue of fitting a stop system to the X-axis of a VMC size machine has been raised a couple of times in MEW – if there is sufficient interest then I could probably produce an article with some detail drawings. Any thoughts David?

Regards

Roger

Steve Talbot 1.