I recently went to Bendigo a gold boom town 150k from Melbourne, the sight of a second hand store was too enticing to pass by.

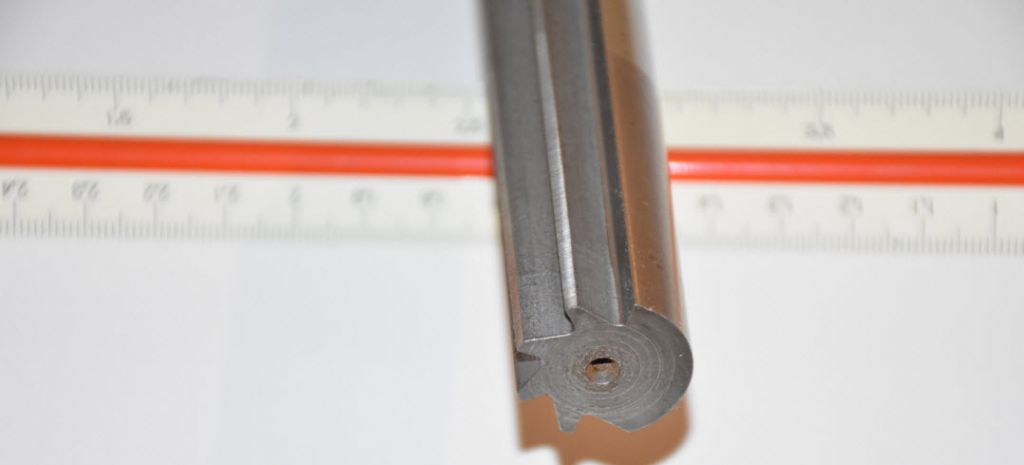

Nothing much until I spotted the 25mm reamer below, I have not seen one of this type before. there are flutes missing leaving a ground segment. The square shank suggests that it is intended for hand use as does the long taper section. maybe it was designed to enlarge the hole as it reams considerably.

There are no makers or any other marks, The shank is soft steel fusion welded to the fluted section that I assume is high speed steel. Not unusual for a professionally made reamer, that method is used all the time for larger drills and reamers all the time.

Does anyone have an idea what its intended use was?

Regards

John

Edited By John McNamara on 14/02/2018 11:49:14

Mike.

]

]