Posted by peter blair on 14/10/2017 02:54:49:

Thanks for the suggestion Eddy but as noted earlier I tried this method without success!!!

Yes, I had noticed that you mentioned trying an impact wrench in the OP.

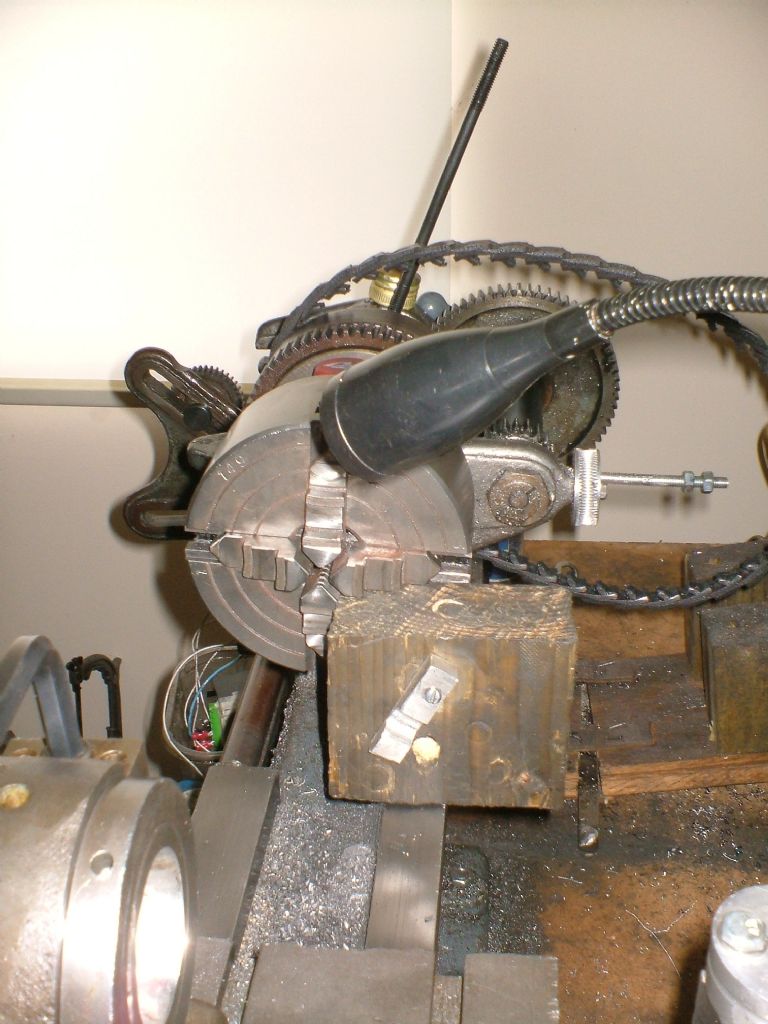

I don't suppose you might be willing to elaborate ? Perhaps mock up and post a picture or two of the approach that didn't work for you ?

Posted by ega on 14/10/2017 09:27:57:

Eddy Curr:

I very much like the idea of loosening the chuck by repeated blows without immobilising the spindle and will try this if the need arises.

Instinctively, however, it would seem that the blows should be "radial" rather than axial and that a hammer tool (as opposed to the mechanic's air wrench) would be less suitable.

Incidently. Notice that a raw piece of hex bar stock is not necessary, a chisel or punch of a size that mates with an available impact socket will do nicely.

Be certain to run the impact tool in the appropriate direction.

peter blair.