As above i was gifted this engine some years ago and asked on MECH and really got nowhere.

As above i was gifted this engine some years ago and asked on MECH and really got nowhere.

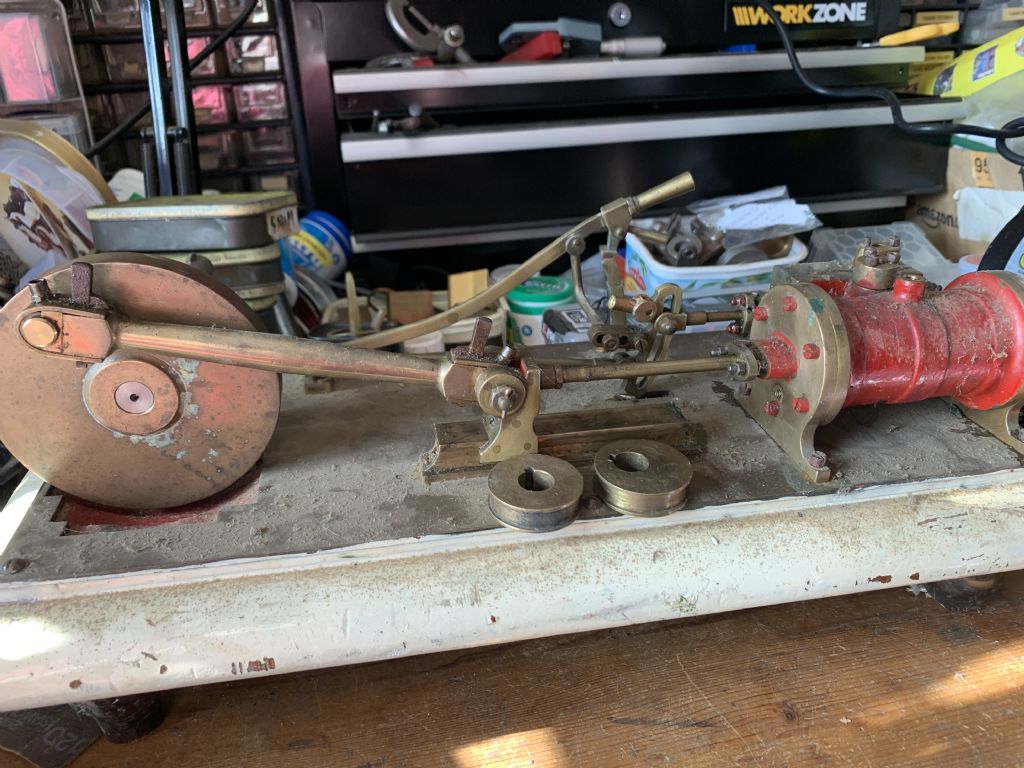

The engine is all brass ecept for the fastners which are steel and the flywheel alone weighs 4 to 5 pound and the eccentrics are pressed out wit very sharo corners

Not going out because all of the snow i got it out again and started again with it trying to find out the pitch of the screws before i could not find any thing, but this morning was trying thread gauges again thought about unf and they could be 5 unf i await in tracy tools foe cheap ta[p and die to try so it could be American,

Where i am really stuck and know nothing about it is the valve gear,

It is supposed to have reversing gear i have a eccentric and a plain drive bush? and have ordered some brass for making the eccentric.

To get down to basics does anyone know how the valve gear works and spell it out for me in simple steps for me to make.? Thanks in antisipation Graham

Edited By Graham Titman on 10/03/2023 17:55:17

JasonB.

JasonB.