Progress on the restoration has slowed over recent weeks. Mainly due to the effects of my booster jab on my illness.

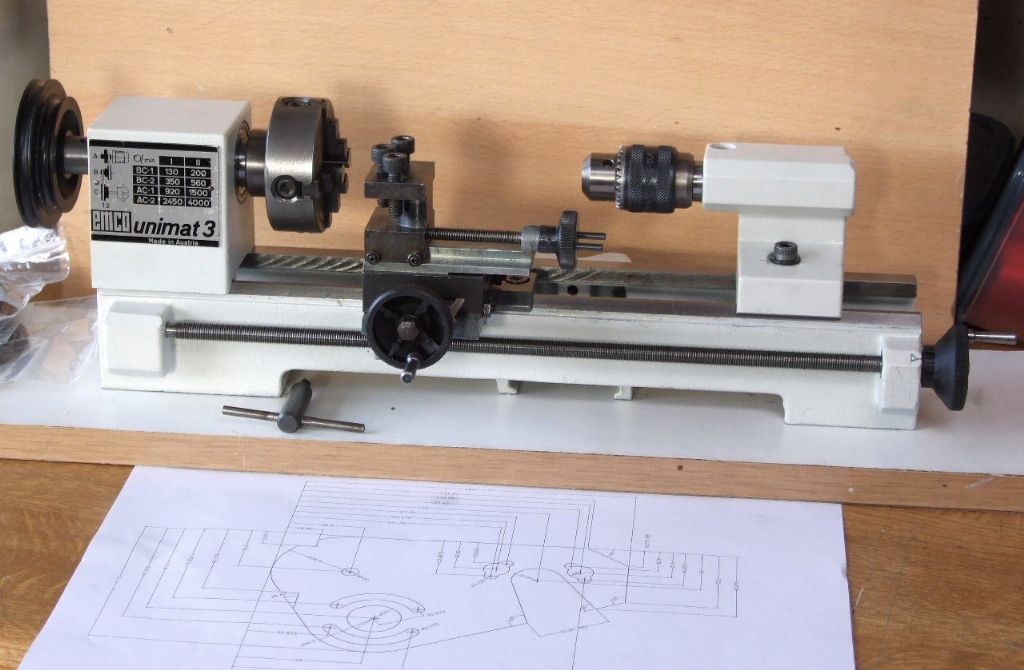

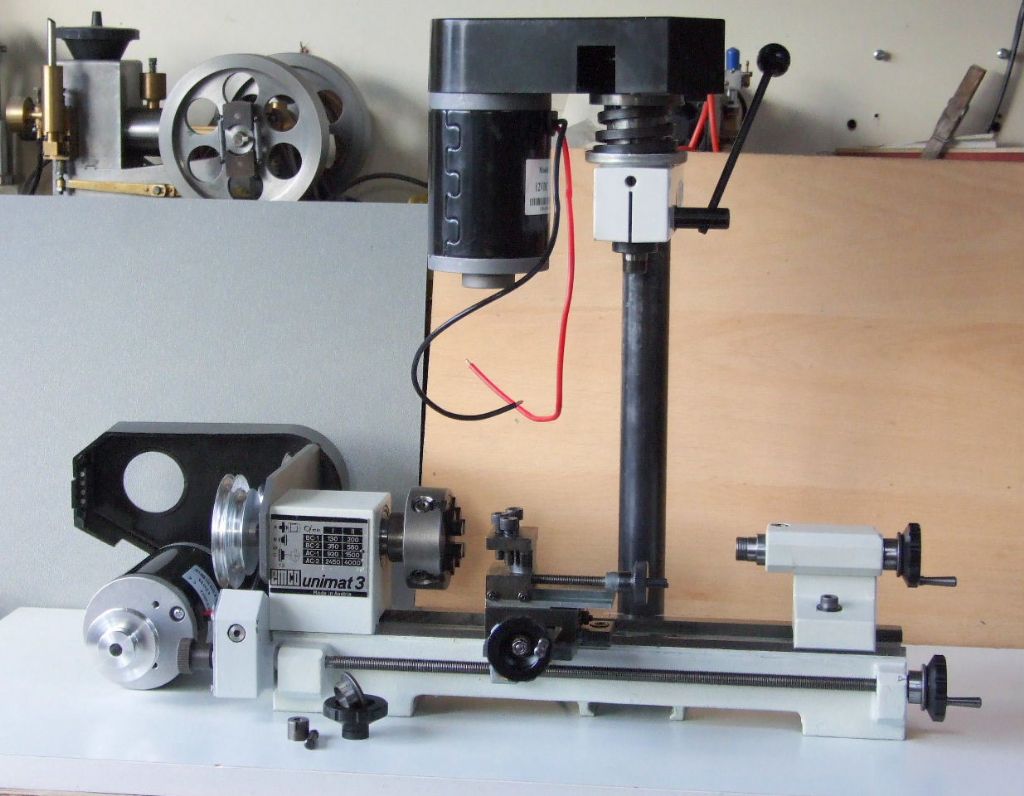

Father Christmas did get his dates mixed up however in that I had an early Christmas present from my Daughter in the form of the Milling attachment for the the Unimat.

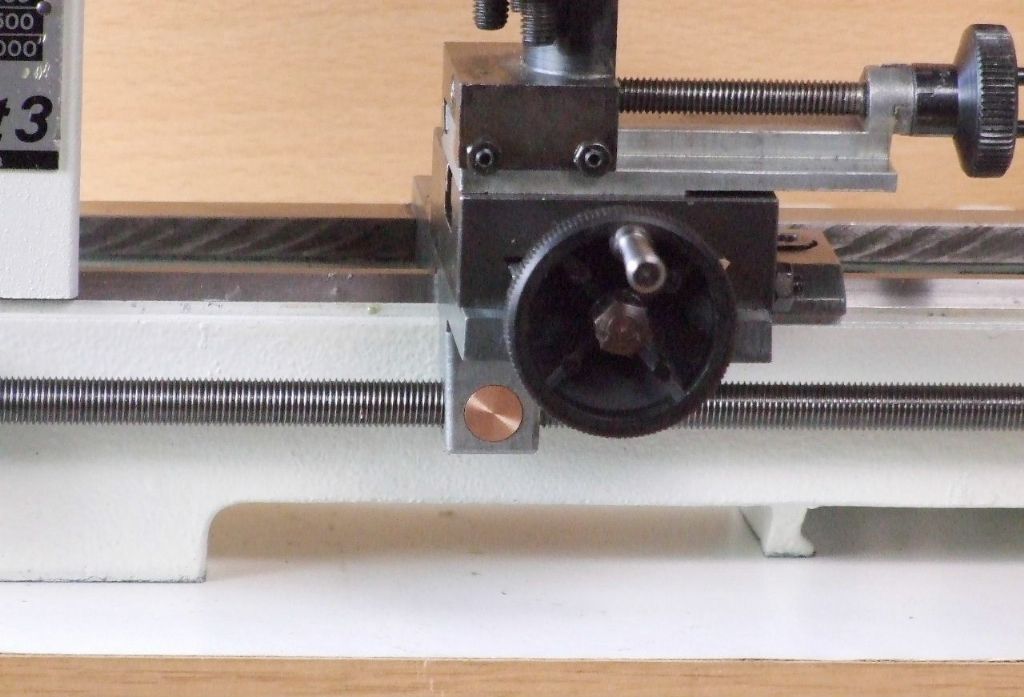

You will see from the above Photograph that the lathe is now sporting some new Handwheels, which have been made in-house with adjustable dials.

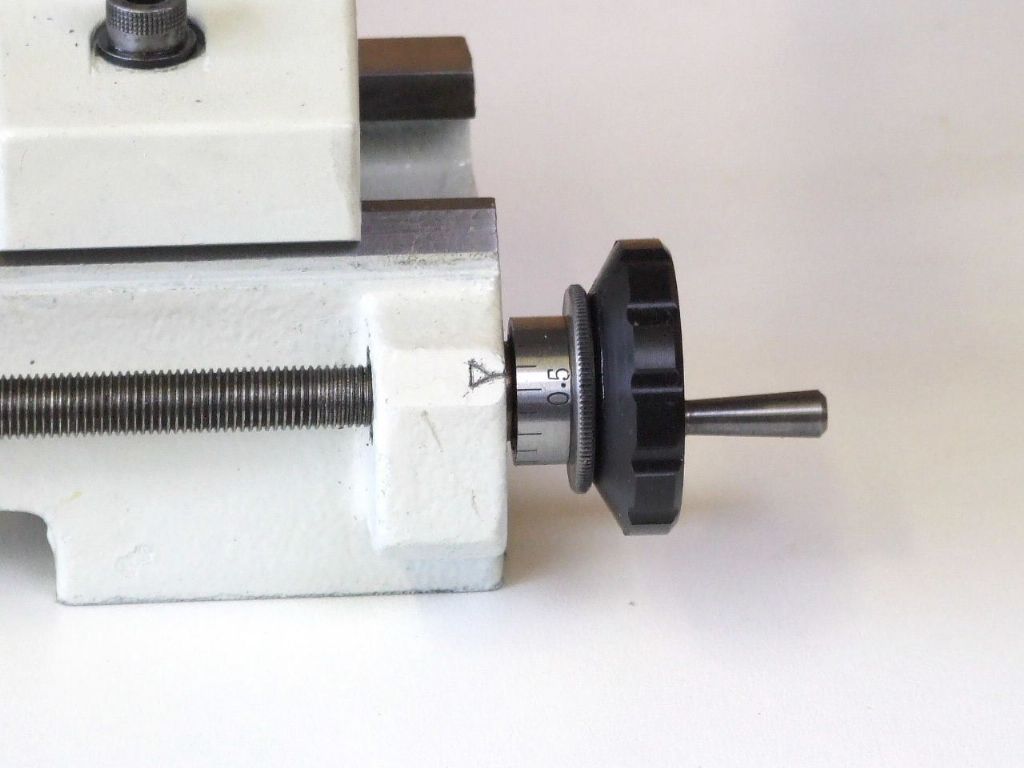

I wanted to keep the Black Handwheel theme going, so the main part of the handwheel was made from Delrin. The small piece of Silicone O-ring acts as a spring to provide friction on the dial by displacing the Delrin ear on the handwheel.

The ear can be seen more clearly in this shot, as well as where the small piece of silicone goes.

This shows the dial in-situ on the longitudinal feed, or leadscrew.

Originally I made one new Idler pulley for the Milling attachment and two motor pulleys, but yesterday I noticed the original plastic mandrel pulley was running out by a mile. When received this lathe was fitted with some vacuum cleaner drive belts. These had been on the machine for sometime while in storage and had given the pulley a permanent set. A new aluminium pulley was duly made.

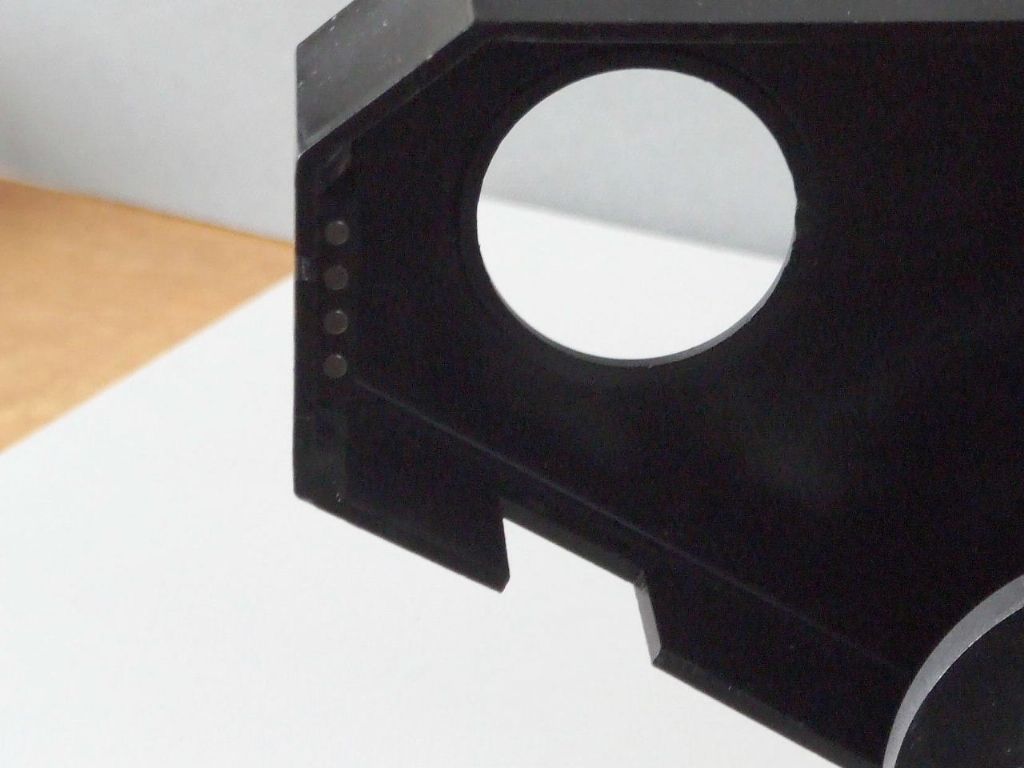

The original integral catches on each guard had been broken at some stage. A piece of Delrin was machined to fit the vacant space and four small magnets were pressed in to keep the guard closed in use.

I tried to mimic the original catch as best I could. The small protrusion makes getting the guard open very easy. The replacement piece is held in lace by two small self tapping screws.

My next task is to make the base board to house the electrics for the motors.

Regards

Gray,

Edited By Graham Meek on 04/12/2021 19:20:57

Edited By Graham Meek on 04/12/2021 19:21:58

simondavies3.