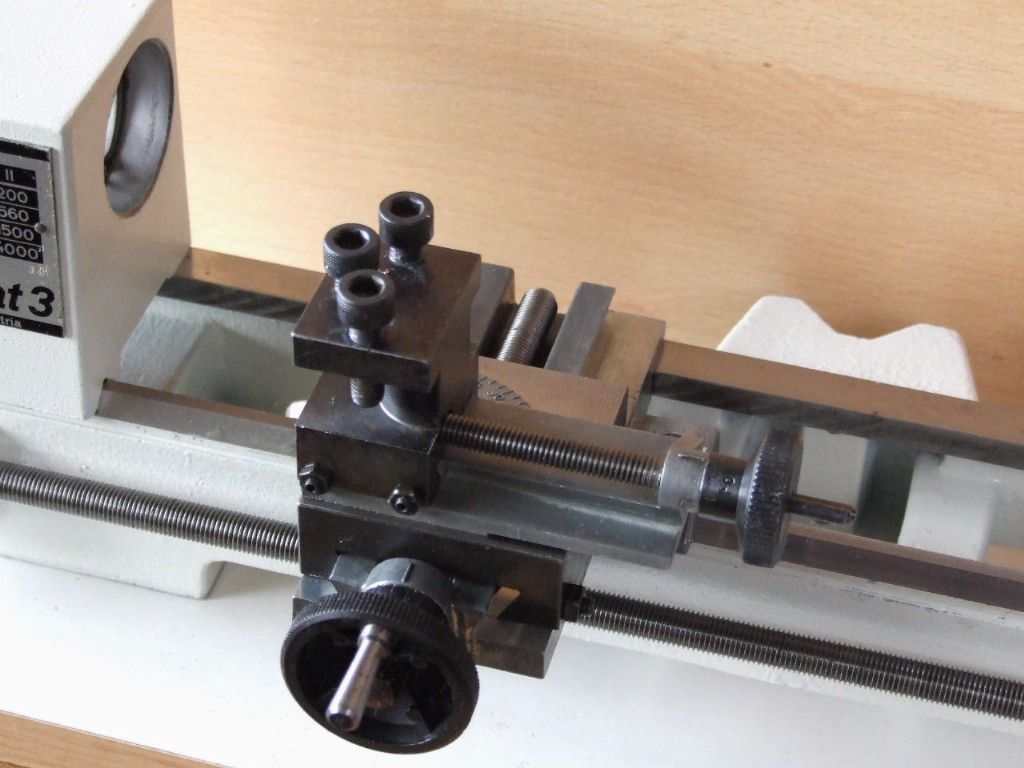

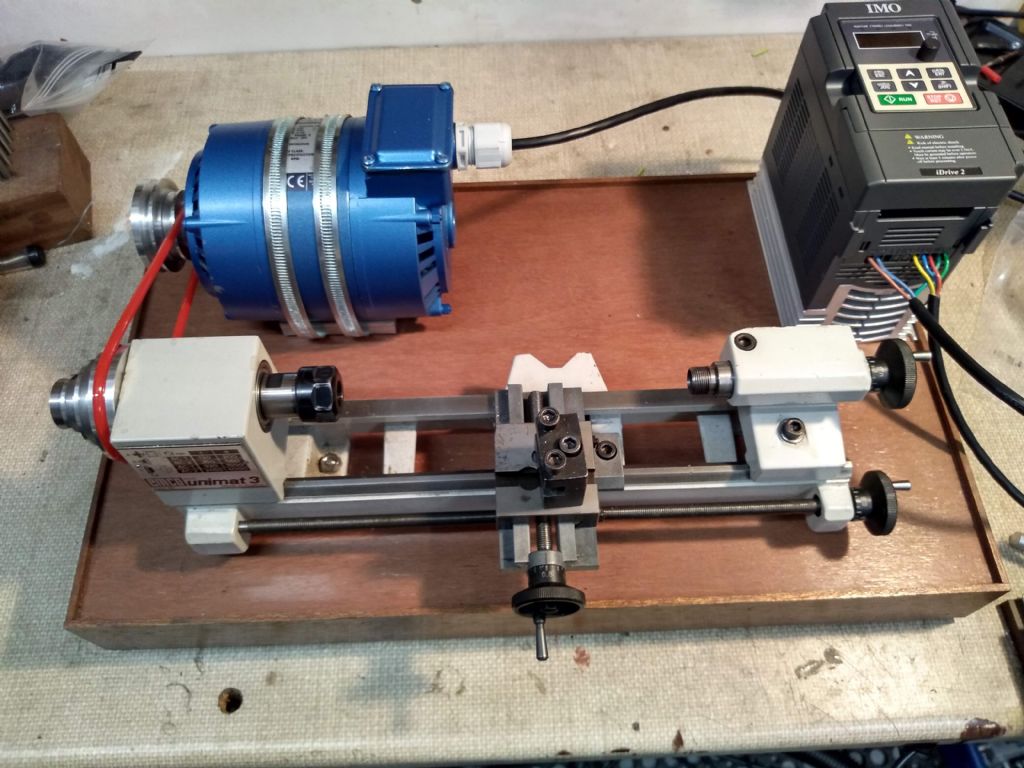

I had a visitor to the workshop recently come bearing gifts. In the form of a much used Unimat 3 less original motor. The visitor said he had been given the machine some years ago and only came across it while clearing out the garden shed.

If I could make use of it, then it was mine otherwise it was heading for the skip.

After removing layers of swarf which had congealed with oil and formed a shellac work was started on stripping the machine. While everything was red with rust the bedways were in good order with some slight staining. Clearly the oil on the bedways had done its job in protecting them.

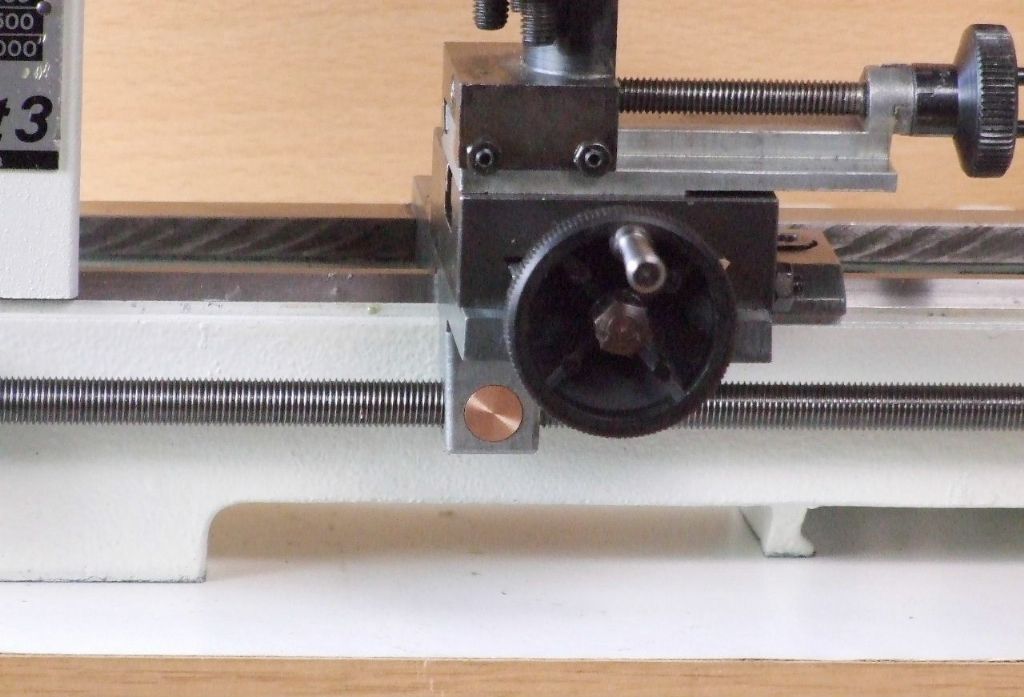

After running a clock over the working surfaces of the Bed there as no more than 0.01 mm maximum wear.

The tailstock working surfaces and the carriage working surfaces were not so good. while there was only about 0.05 mm wear the surface seemed to be filled with abrasive.

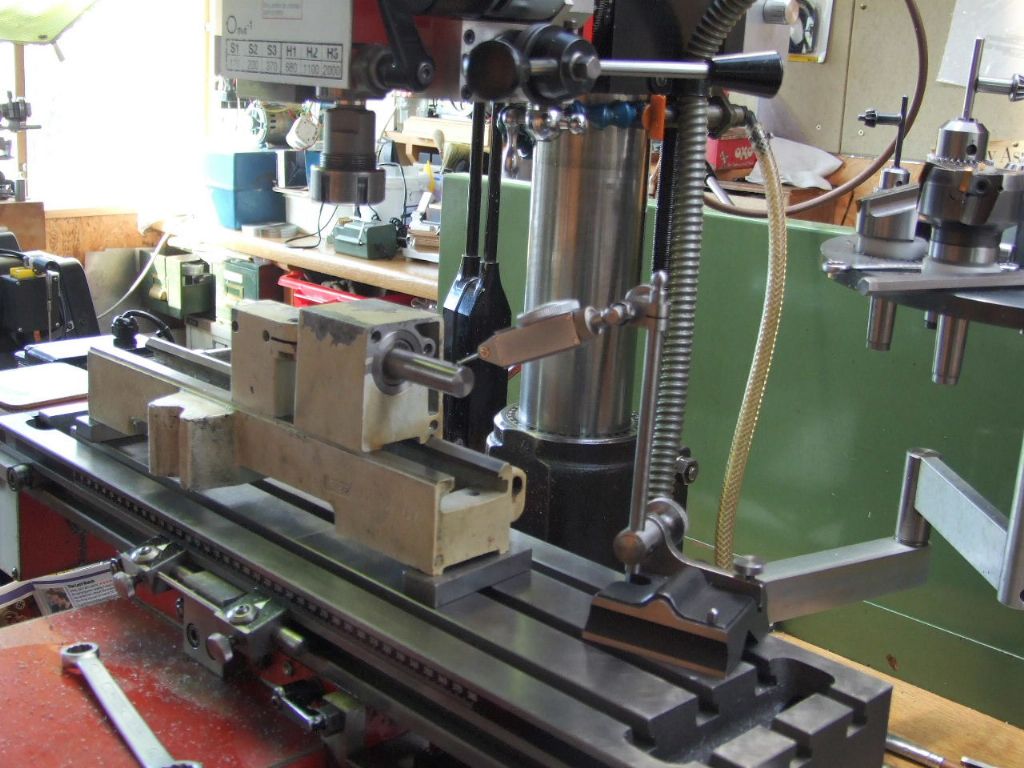

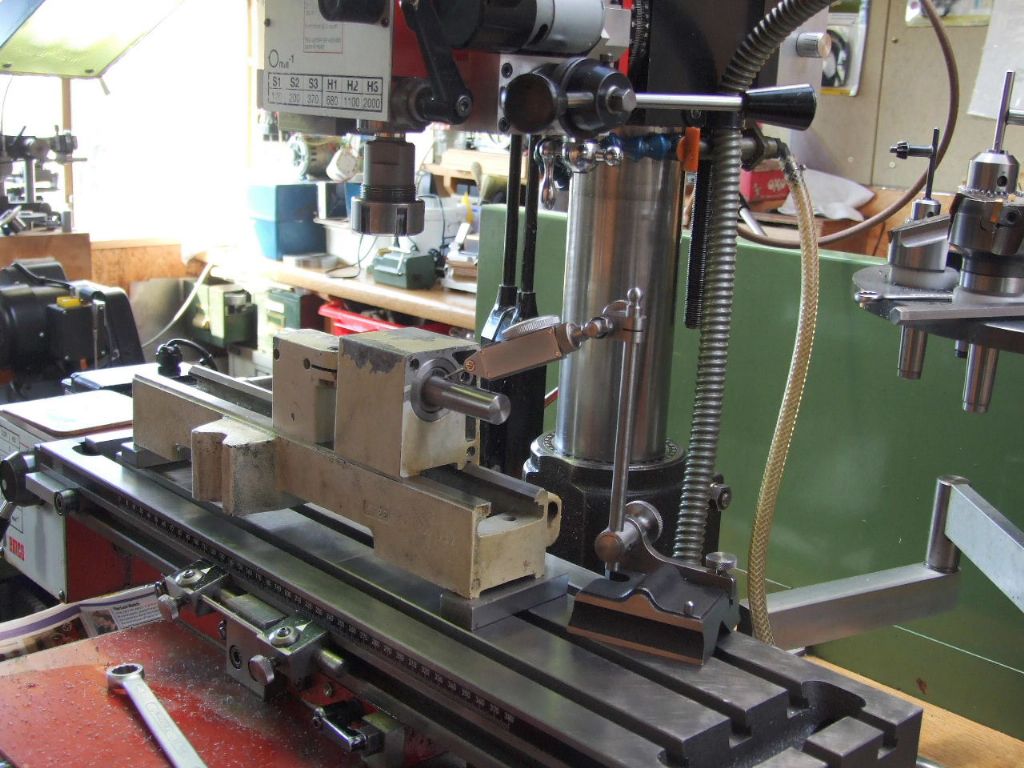

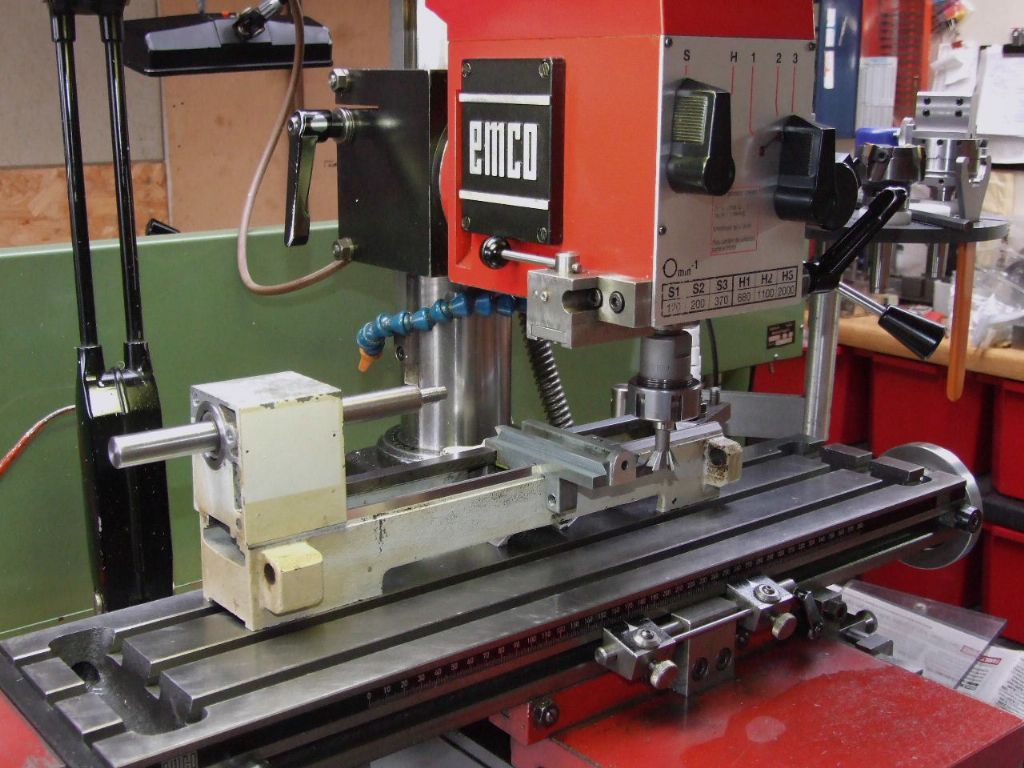

Thus yesterday I made a start on machining the faces back to new. The Vee ways can present problems. Thus I opted for using the Dividing Head to guarantee an exact 90 degrees. Which also made machining the flat easy.

Having the Headstock with an undamaged surface it was easy to establish what height the flat was relative to a roller in the Vee way. Machining the two items on a common mandrel ensured that alignment would be maintained.

Before the parts were removed from the mandrel a check was done on the Bed to ensure the mandrel was true or parallel to the bedways.

The last operation on the Headstock was to put Helicoil inserts in the tapped holes which hold the motor mounting plate, apart from painting.

More to follow.

Regards

Gray,

Edited By Graham Meek on 26/10/2021 16:44:17

Graham Meek.