Hello:

Posted by Kiwi Bloke on 21/06/2023 07:30:02:

… replying to your post above.

Interesting approach. No doubt your approach will work fine. Whether it will continue to do so as it wears remains to be seen. Realistically, it isn't going to wear much is it?

Yes, I thought about it for hours while attempting to imagine just how it would work, if it would work, how much of the contact surface would be lost with the tilt, how much is would wear and at what rate, if it would need more lubrication, etc.

After making a pile of small sketches I settled on the ideas I am putting down below, obviously to be proven (or not) after some sustained use. Taking into account that I am not at the U3 six hours a day, that could mean a relatively long time.

1. … will tend to cause line contact … | … associated with greater wear.

I would be surprised if the wear over (say, 12 months) were to be significant enough to matter. ie: to create a situation where the carriage will act up and affect when turning a piece. The original strips showed wear along a ~3 mm band so checking the state of the brass strips in a couple of months should give us a rough idea / approximation.

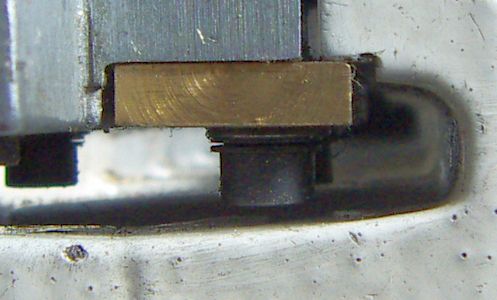

As mentioned, the photograph showing how this arrangement works is an extreme to illustrate the idea.

In reality, when the strips are held in place by the mounting screws they are practically touching the ways before the set screws are turned. As mentioned, the set screws are M4x0.7 and I achieved what I considered to be right adjustment ie: smooth movement of the carriage without discernible lifting or jamming of the strips, with just a touch of the screw.

Just a touch (whatever quantity that effectively is) in this case means a very slight turn of the set screw. Given the pitch, this translates into a very small advance and as a result, a very slight lift of the trailing edge of the strip. ie: practically no pressure between the way and the strip and I assume (here's the scale factor again) a very small angle between both.

I expect that as time goes by, the leading edge of the strip will indeed suffer some wear but as this happens, the contact surface will be progressively increased.

Will have to check and see just how much further on.

2. You could use Belville washers (or other spring washers) under the retaining screw heads to achieve preload. (IIRC, Emco use wavy spring washers).

Yes, the first thing that came to mind when you mentioned pre-load was the use of some sort of spring washer to replace the existing flat ones but have not come up with anything yet. All I have found are grover type washers (split) but I am not sure if they will work properly in this case.

3. … not float on a film of oil … | … There will be metal-to-metal contact.

Please excuse my being so optimistic, ie: ignorant. 8^) Slides would probably have been a more accurate term to use.

4. Don't lose sleep over it. "She'll be right" …

Indeed … But I enjoy the challenge and in turn, learn something new.

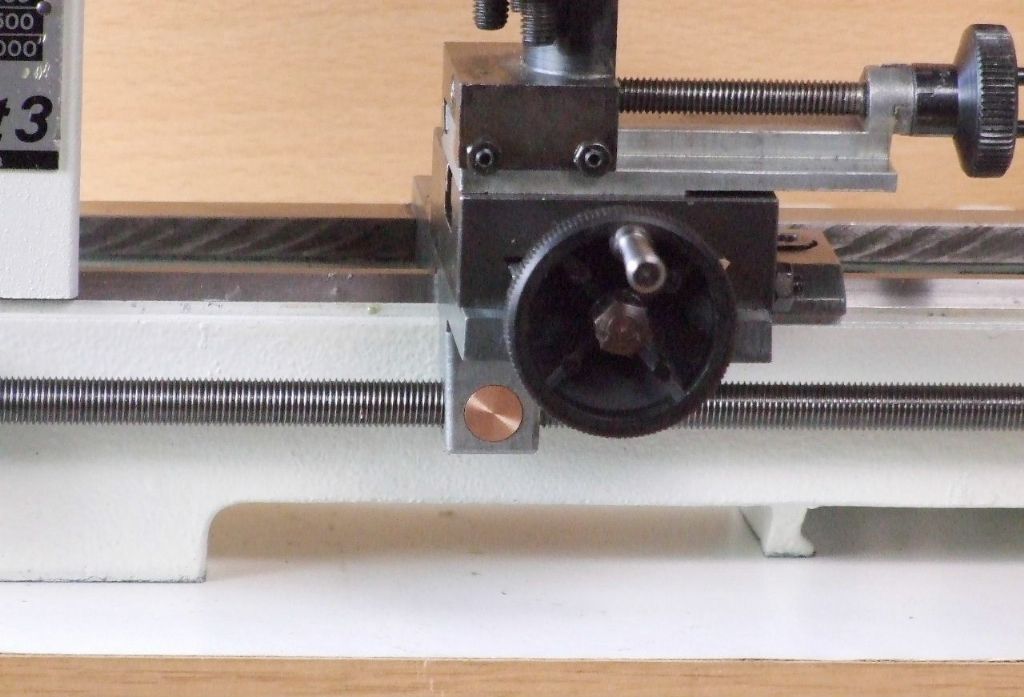

The whole thing is working much better now. A day/night difference with respect to what I was going through when I started the post on the material to use for the gibs.

Thank you very much for your input.

Best,

JHM

Julius Henry Marx.