Hello:

Seeing that the topic that originated this post has been solved, I have split it to continue here in order to address a different but closely related Unimat 3 problem.

Originally started to find a solution to a severe rigidity problem I was having, the idea was to replace the existing lift strips and the post was a query about the suitability of using hard aluminium for making a new set.

Then, at one point (11/06/23 02:08:13), member Kiwi Bloke posted this:

——————————————————————————————————————————————————–

"Some years ago, I obtained an apparently unworn, probably barely used, U3, in a grubby, but not rusted condition. After a complete strip-down and clean, I tried to turn some approx. 3mm dia. MS stock. It was hopeless! It transpired that the mating surfaces of the underside of the saddle held the 'lift strips' a tiny bit away from their ways on the bed, so the saddle could move vertically. Some careful blueing, and needle-file work on the saddle soon had them snug. Problem solved. Check yours!"

——————————————————————————————————————————————————–

What Kiwi Bloke was writing about was exactly my experience, so I immediately started stripping my U3 to check.

After you have done it the number of times I have (more than a dozen) it sort of becomes easy to do. 8^°

Provided you don't lose any parts but please don't ask.

The general process was more or less as follows:

- total stripdown to bare bed + clean/wipe down.

- check bed for warping on a 300mm x 500mm x 8mm plate glass. -> passed

- check ways for warping with the plate on top of ways. -> passed

- check surface of hardwood mounting blocks are on same plane. -> corrected

- reassemble and check no warping had been introduced. -> passed

- mount on its board and check for previous rigidity problems. -> failed ie: same problem as before

Once finished with all that, I concluded that I could (?) rule out other sources of trouble. Time will tell but for now this was a welcome relief.

I then checked to see what was going on with the lift strips.

Moving / lifting the carriage enabled me to visually confirm that the problem was exactly the same as the one described by Kiwi Bloke in his post: the properly tightened lift strips were not making proper contact with the guides under the ways.

But here's the thing: before deciding to purchase the U3 and then after taking it apart for the first time, I spent countless hours scouring the web for anything related to drawbacks, problems, fixes, workarounds, useful modifications, etc. and while I cannot possibly claim to have read everything out there, I can confidently say that I never came across any reference to the problem Kiwi Bloke posted about.

Maybe it got lost when some user group shut down or the hosting service went down, no way to know now, but here it is.

For that very reason I was dead set on documenting the work on the lift plates' mounting surfaces but my digital camera decided not to help by ignoring the SD card inside the slot and insisting there was nothing there.

But I digress.

Once I had a clear idea of the (very) slight amount of material that had to be removed, I decided to use an old and worn down 6"x5/8" flat file to remove the excess material, a tiny little bit each time.

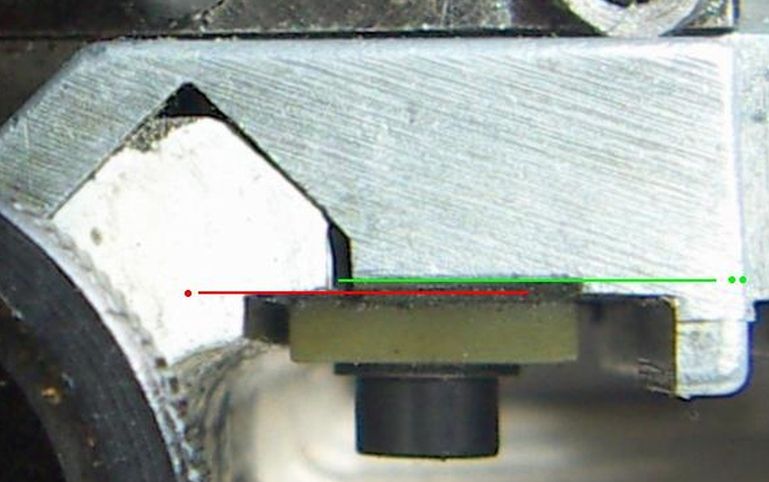

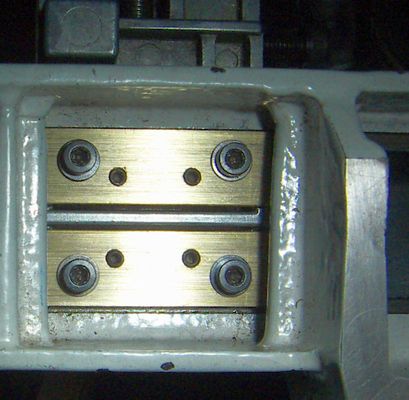

Here is a photo showing what Kiwi Bloke wrote about:

The red line coincides with the surface underneath the front way where the lift strip has to tightened against and the green line coincides with the surface to which the lift strip is tightened.

Due to a bad photograph, a shaky hand/mouse using mouse/MSPaint and a number of optical effects I cannot recall how to explain, the difference observed between the lines is really much less that what it appears to be.

But it boils down to this:

If both lines are at the same level, the lift strip will not touch the surface underneath the way and the carriage will move upwards, so the green line has to be above the red line.

The same thing obviously applies to both lift strips.

After a countless number of iterations ie: filing the surfaces, mounting the carriage, tightening the lift strips, checking the carriage movement and then unmounting it again to file off some more material, the stars finally started to line up.

And the problem seems to have been fixed. Although promising, the jury is still deliberating.

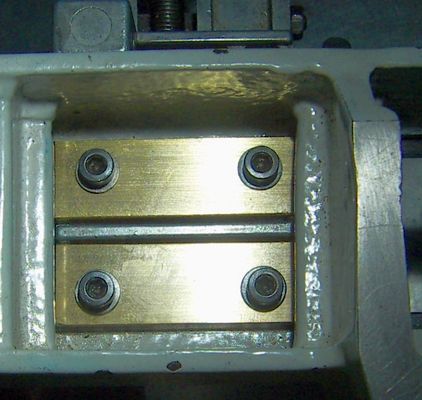

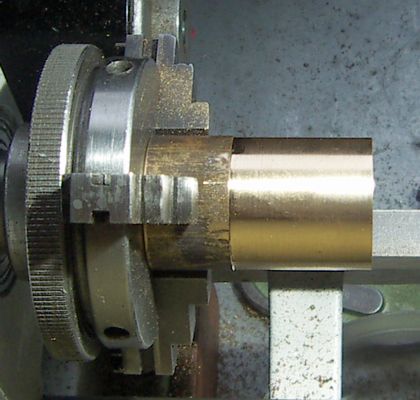

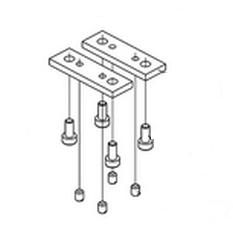

As I will be replacing the ca. 1980 OEM lift strips with a new set made from 5/8"x5/32" brass, there will be photos to show what was done along with a description on how it was done to be kept here at ME for other U3 owners looking for a solution.

I don't want to end this post without first tipping my hat to Kiwi Bloke for graciously posting both about the problem and a proven solution.

Unless something else comes up, I hope to be posting further comments and a couple of photographs in a few days's time.

Best,

JHM

Edited By Julius Henry Marx on 16/06/2023 22:44:51

Julius Henry Marx.