Hello:

Posted by Kiwi Bloke on 28/06/2023 11:11:48:

… making life difficult for you…

Well … If it were only the U3 … 8^)

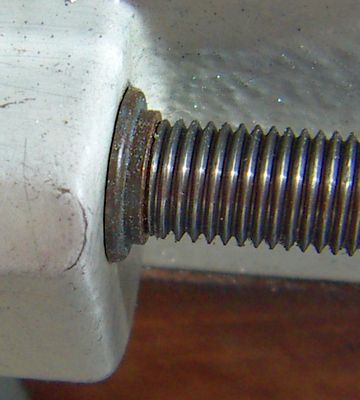

For the time being I am doing (surprisingly) well with the washers, handwheel surgery, etc. so that is not a huge problem at the moment, but I don't want this hack to be a perma-temporary thing.

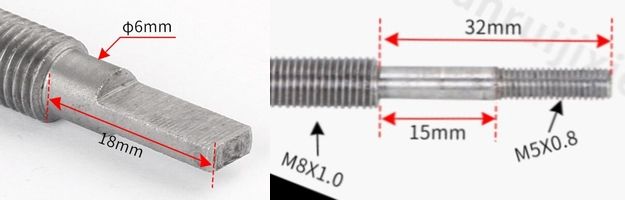

So I have sent for a replacement feed screw from a vendor of all things Sieg at Aliexpress. If the photos are anything to go by, it looks like it is much better made than the one from my U3:

The main reasons for having sent for a new one (aside from the original one being 43 years old and in awful shape) being the ready-made availability and the real life difficulty of getting a shop to make a bespoke one for me, much more being just one and not two dozen.

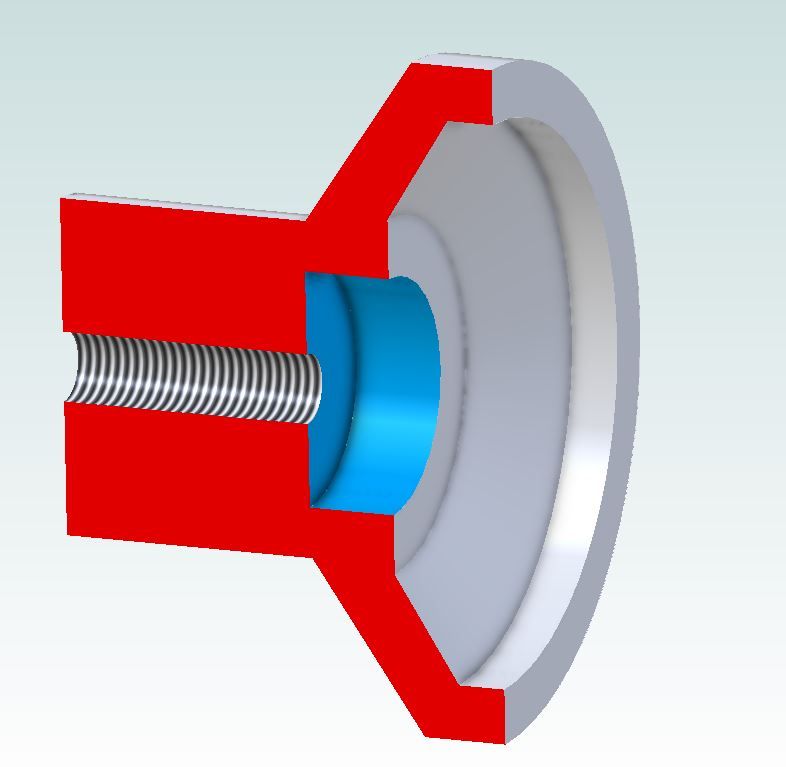

My plan is to make a part with the same diameter as the left end of the leadscrew (6mm) and a full length concentric hole with a M5x0.8 thread, obviously with a non-threaded part for it to fit properly.

This part will most probably be made out of hard bronze and be threaded into/ locked with a suitable (soft) anaerobic to the right end of the screw. The length this part will be defined when I decide how to fix a new handwheel and/or some attachment. eg: a toothed pulley to drive the feedscrew FF / FR using a small 12V motor.

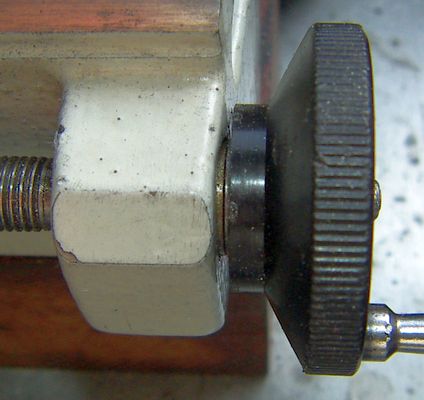

The right end of the feedscrew, now having a longer ⌀ 6mm end with a male M5x0.8 hole will run inside a new, longer steel bushing with a flange on its right side, maybe with a small recess to hold a small thrust bearing if I can find a suitable one.

…. improvise a temporary saddle stop … | … turn the end of the leadscrew.

I thought for some time of doing that same thing before fixing (?) the lift strip problem, but concluded that it was not something to do without risking making things worse.

Thank you very much for your input.

Best,

JHM

Graham Meek.

![20230627_073529[1].jpg 20230627_073529[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/925524.jpg)