Hi All

Turning a taper spindle collet on its own lathe.

This may have been posted before although I have not seen a post recently.

I needed to make a MT3 and NT40 plug collet to fit directly in the spindle of the lathe.

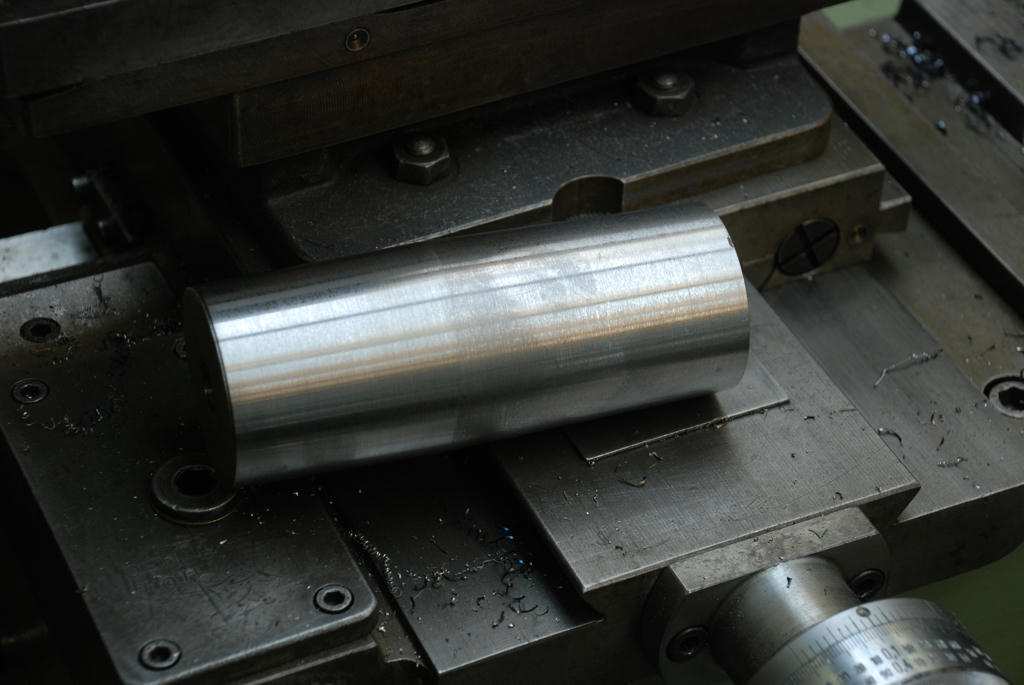

So a piece of stock was selected that was long enough to make the two with a 15mm extra allowance in case the taper did not fit first time and to allow for cutting them apart and facing The plug is about 65mm diameter at the widest point.

The following cutting sequence was used.

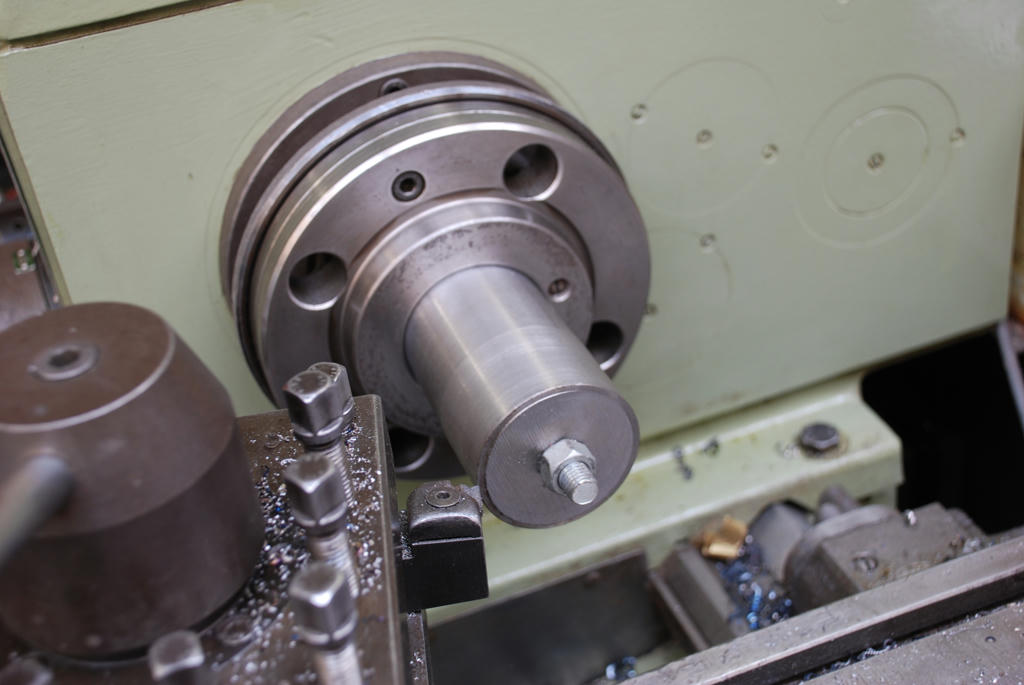

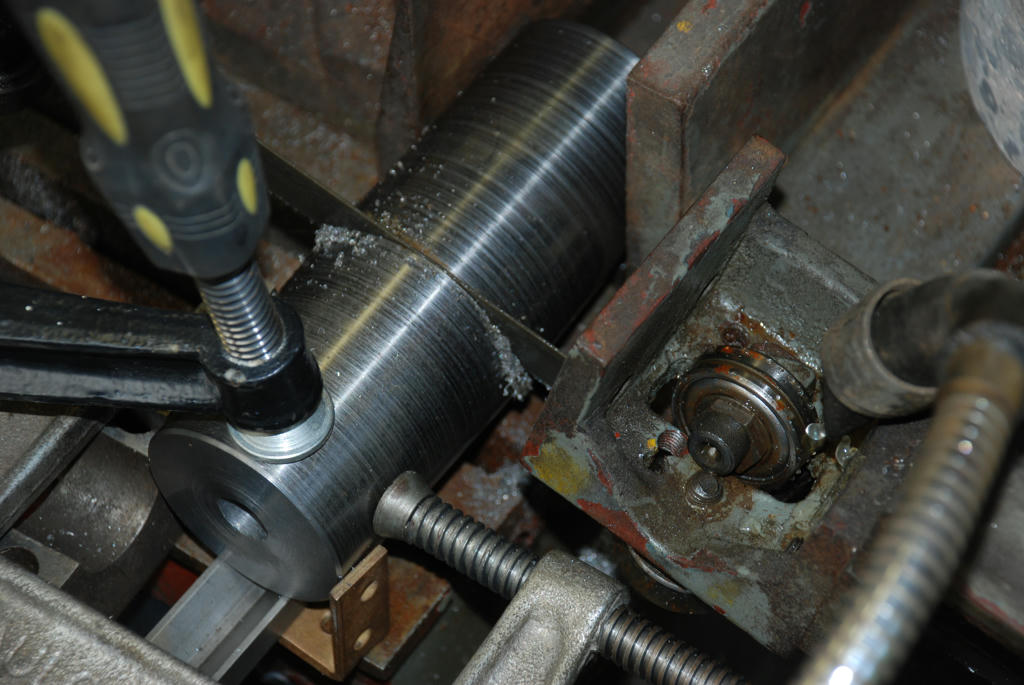

After measuring the taper with a protractor I set the top slide to match the taper. Then I mounted the three jaw chuck and I skimmed the diameter to remove the scale then bored a Half inch hole half way through from the tailstock then reversed the work piece and bored from the other end and creating a through hole, as it happens it was fairly true leaving a clearance hole for a 12mm all thread rod that would be used later to clamp the collet. next both ends of the piece were faced. Then after rechecking the material holding tight I made the first taper cut.

Leaving the piece in the chuck I removed the chuck and tried the taper cut using a little marking blue. It was a little out so I nudged the top slide and reinstalled the chuck made another cut and tried again. This time it was (about) right. “That L Do” ! (something I do not often say)….. I removed the piece from the chuck and removed the chuck.

Face:

Continued next post…..

Edited By John McNamara on 13/11/2011 05:12:02

Andy taylor 2.