TurboCAD Query: Maintaining Rendering Acrss File-types?

TurboCAD Query: Maintaining Rendering Acrss File-types?

Home › Forums › CAD – Technical drawing & design › TurboCAD Query: Maintaining Rendering Acrss File-types?

- This topic has 112 replies, 18 voices, and was last updated 18 April 2023 at 17:47 by

Andy_C.

-

AuthorPosts

-

12 April 2023 at 12:09 #641019

Nigel Graham 2

Participant@nigelgraham2Thankyou Andy.

What variant of TurboCAD do you use?

Mine is "2021 Deluxe – x64 " ; but I think this is the basic edition of 2021, hence such limits as no full chamfering and filleting tools.

.

I am afraid I do not understand TurboCAD (or any CAD) as far you credit me with! I know what it can do, but not how to ask it to do that. I cannot reach your level with it; but by my weakness, not its strength.

.

I prefer TurboCAD for its 2D/3D capability rather than the default 3D-first approach used by Solid Edge, etc. I can make the proper drawings relatively easily; leaving rendered isometric images for occasional use where dimensional accuracy, aesthetic quality and practical value are not important.

For the 3D-first way adds a vast extra load of specialist CAD knowledge, before you can use it to help designing items to make, for which the orthographic drawings are still necessary. I do know you can derive the elevations from a 3D CAD model – you don't draw the thing twice – but this is the long, hard way round.

So, the 3D mode is merely an option. Those rough 3D pump pictures were to aid discussing a particular physical problem. I cannot use 3D to design those pumps – or a machine-tool accessory, let alone my steam-lorry. Yet I lose nothing because TurboCAD offers a direct orthographic bypass to the 3D barrier.

.

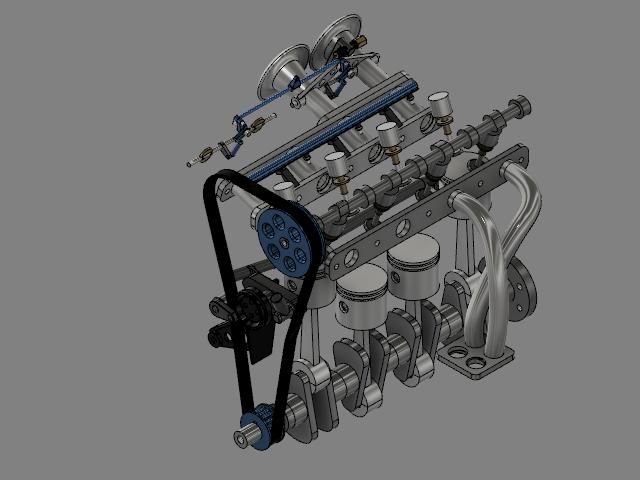

TurboCAD is as capable as Fusion, SE or Alibre for renderings like Nick's car-engine (above); and including the engine's internals even if those become hidden. For the experts….

I know the different CAD makes are very different in approach but probably equally hard or easy to learn, as that depends on your ability, not the product. The only influence the makers have is the nature of any tutorial and reference material they might deign to cobble together. As I have pointed out, they aim their primary sales at industry, not hobbyists, so assume the programmes are taught in proper, comprehensive, formal courses.

I am though surprised that the majority of model-engineering CAD users seem not to use TurboCAD even though it is just as powerful as its rivals (perhaps more in certain respects), offers a direct 2D/3D choice, and has been readily available by simple single-purchase for a long time, since well before the others showed up.

Its UK agent, Paul Tracey, has stopped advertising TC in the magazines, and he was not at the Harrogate show as fas as I know; but I don't know why this is.

12 April 2023 at 12:46 #641025Nealeb

Participant@nealebI used to use TC but only ever in 2D. When I first bought a copy (cheap, found in a closing-down sale of a software place in the US when on a work trip!) I thought it was great. And it was – better quality drawings in less time than I could otherwise manage. I'm a scribble on the back of an envelope kind of model engineer otherwise. I upgraded a few times but never to a point where I found the 3D part usable. I worked, with difficulty, through the tutorials but never managed to do anything of my own. 2D was fine, though – until I started more ambitious drawings when I found the ability to go back and change things lacking. Anything significant to change and it was easier (for me) to scrap it and start again.

Then I found OnShape, which was a revelation in terms of 3D CAD. I did some drawing office training many, many, years ago so was at least aware of some of the principles but not enough to make unlearning too hard when picking up 3D. I've tried to help a few people get going with 3D CAD and I try to emphasise that you are not trying to create a set of engineering drawings, but to build a 3D model from which the software creates the drawings later. OnShape was OK, but at that time a bit limited, and along with a few other ME colleagues we all more-or-less at the same time found and started using F360. Much better! And the CAM was a bonus. 2-3 years ago I moved to Solid Edge as being more powerful in the CAD department, although I still export models to F360 for CAM. I found F360 to start getting a bit fragile when building more complex assemblies and SE seems to work better for me. I use 3D modelling rather than 2D drafting because I am building a loco to a published design and building the computer model gives me so much more insight into how the bits go together than just looking at the 2D drawings. And it's needed anyway to use CNC, so not wasted effort.

Anyway, as a model engineer. I moved away from TC because I could never get past "drawing in 2D only" and even then struggled to get the flexibility and ability to edit that I have found with the newer tools. 3D suits me much better, and I haven't had any particular problem adapting to the 3D modelling approach.

12 April 2023 at 13:44 #641037Nick Wheeler

Participant@nickwheelerPosted by Nigel Graham 2 on 12/04/2023 12:09:39:For the 3D-first way adds a vast extra load of specialist CAD knowledge, before you can use it to help designing items to make, for which the orthographic drawings are still necessary. I do know you can derive the elevations from a 3D CAD model – you don't draw the thing twice – but this is the long, hard way round.

So, the 3D mode is merely an option. Those rough 3D pump pictures were to aid discussing a particular physical problem. I cannot use 3D to design those pumps – or a machine-tool accessory, let alone my steam-lorry. Yet I lose nothing because TurboCAD offers a direct orthographic bypass to the 3D barrier.

.

TurboCAD is as capable as Fusion, SE or Alibre for renderings like Nick's car-engine (above); and including the engine's internals even if those become hidden. For the experts….

You keep saying that 3D first requires extra and specialist knowledge, but so does 2D draughting – much of it even more arcane, hard to explain and demonstrate. It doesn't take much knowledge or ability to start just knocking bits off a cube to get what you want, but it isn't particularly efficient whether it's on a screen or the bench.

Nick's engine image isn't a rendering, but straight from the design space. I don't have the artistic knowledge to use the settings to create pictures that don't look like cheap cartoons, and won't get any value from proving that again.

That engine started from a single sketch of three circles and two lines that define one crank journal:

with copies made, offset and jointed appropriately to create the whole crank. That offset was defined as a parameter and reused similarly for the bores, valves, ports, throttle butterflies and many other parts. Definitely not the long way around! The most difficult bit was creating a plausible exhaust manifold using 3D splines…

Since I finished it, Fusion gained a tangential joint so even the valves are now animated by the cams, which shows the clearance. Each part is defined as the appropriate material – aluminium for the block, steel for the crank, brass for the butterflies etc – and Fusion suggests the whole assembly will weigh 3328g.

If I ever do get around to building this, the block and head will require more thought, as they could only be made by casting – the block would be better split into separate, machinable crankcase and cylinder blocks, just as the cam boxes are separate to the head.

If I'm honest, a single cylinder engine is all I really need to make, as a four cylinder(better yet a V6) is just lots of tedious repetition.

With the complete model available, separate orthographic drawings with all their compromises won't be necessary to make many of the parts.

12 April 2023 at 14:09 #641039SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 12/04/2023 12:09:39:

…

Mine is "2021 Deluxe – x64 " ; but I think this is the basic edition of 2021, hence such limits as no full chamfering and filleting tools.

I am afraid I do not understand TurboCAD (or any CAD) as far you credit me with! I know what it can do, but not how to ask it to do that. …

I prefer TurboCAD for its 2D/3D capability rather than the default 3D-first approach used by Solid Edge, etc. I can make the proper drawings relatively easily; leaving rendered isometric images for occasional use where dimensional accuracy, aesthetic quality and practical value are not important.

For the 3D-first way adds a vast extra load of specialist CAD knowledge, before you can use it to help designing items to make, for which the orthographic drawings are still necessary. I do know you can derive the elevations from a 3D CAD model – you don't draw the thing twice – but this is the long, hard way round.

So, the 3D mode is merely an option. … Yet I lose nothing because TurboCAD offers a direct orthographic bypass to the 3D barrier.

…

TurboCAD is as capable as Fusion, SE or Alibre for renderings like Nick's car-engine (above); and including the engine's internals even if those become hidden…

…

I am though surprised that the majority of model-engineering CAD users seem not to use TurboCAD even though it is just as powerful as its rivals (perhaps more in certain respects), offers a direct 2D/3D choice, and has been readily available by simple single-purchase for a long time, since well before the others showed up.

…

It's been pointed out in this and several other CAD related threads that switching from 2D to 3D design requires a difficult change of mindset. Though I expect Nigel will deny it, I think his latest post confirms he's not made the jump yet. Not his fault and nothing to do with intelligence. When 3D-CAD first arrived in drawing offices, something like 20% of the most productive draughtsmen had serious conceptual problems with it. A sort of mental inversion is required, plus accepting that most tried and trusted technical drawing techniques are irrelevant. Worse, they have to be consciously ignored.

In 2D-mindset 3D is a barrier, software that goes the long hard way round to produce something unwanted. If this perception was correct no-one would use 3D-CAD. Fortunately for designers everywhere, the 2D-mindset view is wrong; 3D isn't an option, it's a step-change improvement, that makes lots of 2D work unnecessary. 3D-CAD simplifies many operations, the output is more comprehensive than just 2D drawings, and the method is highly time-efficient. Though I use them all, for anything other than trivial work, 3D-CAD easily outperforms 2D-CAD, which leaves manual drawing board methods in the dust. Denying this basic truth is a waste of time. Unfortunately 3D-CAD is skilled work and there's a lot to learn, even if a 2D mindset isn't blocking the road.

The statement that TurboCAD is as capable as other programs is misleading. There are 4 different versions of TC ranging from Deluxe (with limited 3D), to Platinum (full throttle). The main advantage of Deluxe is it provides a strong alternative to AutoCAD-LT (2D), plus a limited 3D capability limited to surfaces. This is why it can't do chamfers – a surface is a zero-thickness skin stretched over a wire-model. It looks like a 3D solid, but isn't, and you can't chamfer a surface! TurboCAD-Platinum does Solids, chamfering is a button click, and I suspect many of Nigel's other struggles would disappear if he paid for the full version.

Just a guess from the product description, but I think TC's roots are an alternative to the once super-popular AutoCAD, the original 2D par excellence. Later 3D features were added to a product set offering a gradually improving range of capabilities. Compared with SE and Fusion they seem very limited in TC deluxe, and far more comprehensive in Platinum. I guess what puts most amateurs off is the cost of TC in full strength. I found trying a demo version hard work, probably because I too have a mindset!

In my exploration of 3D-CAD, I liked FreeCAD but saw clear advantage in Fusion. Fusion came with features like the implications of being in the cloud, so I switched to SE which had obvious benefits for me. Not as easy to learn, but more than I need, with no cloud issues. I can't see anything about TurboCAD that would cause me to switch. TC would be in a strong position had I started with AutoCAD in the distant past, but I didn't, and it's expensive.

Dave

12 April 2023 at 18:30 #641075Nigel Graham 2

Participant@nigelgraham2I looked at prices, and relatively, TurboCAD is not much different from its competitors but we do need look at the versions offered and there is a huge jump from TC's lowest to highest. I used the manufacturers' own sites.

TurboCAD Deluxe (lowest in the range) £80 (with certain tools as well as a few, major functions removed)

""" Professional 300

""" Platinum 400 (to nearest £, from £xx.99s)

Fusion 360 Free hobby use, but lacking what stripped from its commercial version, roughly £500/year?

SolidEdge / Solid Xxxx No prices given, to subsidise their extravagantly bloated web-site.

Alibre Atom £240 in VAT; £334 in VAT with 1-year "maintenance" – but these were still the 2019 prices!

I suppose it depends what you want. TC Deluxe looks so cheap I wonder if I missed a preceding "1".

.

Mindset?

I don't have a "mindset" , in any number of dimensions, but I wish people wouldn't assume I have.

The Technical Drawing I studied at school included three-dimensional topics such as Interpenetrations, "Lines In Space" (the teacher warned us those are very difficult), Helices and Isometric Projection.

Equally, in Maths, I found 3D graphs (x, y, z) easy perhaps thanks to familiarity with Ordnance Survey maps, engineering-drawings and of course, our 3D world. It was the abstract stuff that baffled me, like the Matrices I met some decades later.

In my last few years at work I met orthographic parts drawings with coloured 3D images in the corners to show what the article would look like. Over the years I had become familiar with isometric sectional and assembly drawings in various ways.

So I knew what CAD could do for me, if I could learn it, even before I bought it.

.

I knew I had to approach its as its own field of knowledge on top of knowing engineering-drawing methods, as if expanding knowing Yorkshire geographical name elements to learning conversational Norwegian.

The reason for my liking TurboCAD's 2D/3D option has nothing to do with "mind-sets" or any other cod-psychology diagnoses over t'Net! Believe it or not, I do know how I think, how I succeed or fail to learn, anything – not just CAD or Mathematics or Languages – and importantly, recognising my limits.

It is very simple: learning ability, a matter of understanding and sheer bulk memory.

.

We need dimensioned drawings in the workshop, and these are usually orthographic; however made. TC wants you to create them from a 3D model; just as Fusion, SolidEdge and Fusion dictate; but unlike those, gives you a direct 2D/3D choice.

That helps me only because I find 3D CAD modelling very hard to learn; and although still difficult, TurboCAD's orthographic mode is much easier. I found Alibre and SE no easier; plus having to learn completely new systems from almost nothing, made a combination too much to take.

It's as simple as that! Learning limits. Not some anti-3D motive.

.

I think we all have natural limits to what we can learn, to what extent. Mine are low and very random. I found 3D graphs easy and matrices (weird boxes of numbers) impossible, to understand; yet both are mathematics topics. Similarly I taught myself the drums moderately well, can probably still knock off a paradiddle or two, but failed to learn the piano and guitar – all musical instruments. While despite the same equipment and methods, I can visit one cave but not another of comparable overall nature and difficulty if the latter contains an obstacle possibly very short, but still too difficult for me.

.

If I fail despite all attempts, my mind's self-defence is instinctive locking-down as "impossible" ; and It need not be a big obstacle or entire field of study. Sometimes I have broken through the barriers, or they did not exist at first, only for them to return later and impregnably. I cannot explain it, but if my brain is of the same biology as anyone's, I imagine I am not alone in this.

So, I can't make much progress with 3D CAD not because it is 3D CAD, but simply because it is very hard soft-ware. (!)

Yet I had hoped to learn it to the advanced level you all find easy, accept as normal and might even take for granted, so I can use it to help my engineering.

'

Incidentally, I looked briefly at Fusion 360, but its only tuition materials were videos, no use to me.

However, I learnt you do not need save your files on Fusion's default Internet account (why "The Cloud" ?). You can (at least, could) save them locally.

There is a serious home-security aspect to saving any material on-line, but it rather amuses me to think of some Beijing or Washington agent puzzling over your beautifully-tinted 3D drawings for a Myford ML7 accessory or miniature locomotive cylinders.

12 April 2023 at 20:24 #641087Andy Ash

Participant@andyash24902I use TC 2016 Platinum. I have had no desire to upgrade to a newer version, but I always keep my eyes peeled for second hand deals. People do want to move on, and when they do, they can get something for their old licence. I just had a look and TC is cheaper this year than it has been previously, so perhaps they're yielding. Maybe at the price I might be tempted.

The one thing that I think my version of TC lacks is kinematics. The modern CAD packages do that in the blink of an eye, and I wonder if that is why the price of TurboCAD is yielding. It isn't critical for me, I just need to be able to model solids. I work out loci and envelopes by other means, but I'd be keen to use it if it were available at a price I could afford.

Edited to add;

I was just looking at the current annual price not the perpetual one. It's the way they lay out the website. I wouldn't buy the annual licence, and the perpetual one is more than a 1k GBP. I couldn't justify that for the use I will give it. For 1k GBP I'd expect the kinematics to be there, but lots of people don't need it and will make money using the software even without it.

I still like the way TC works though. I suppose it's just that I've been using it so long.

Edited By Andy Ash on 12/04/2023 20:34:06

12 April 2023 at 20:28 #641089lee webster

Participant@leewebster72680It seems to me that TurboCad is better at 2D than 3D, whereas the cad programmes I have used are the other way round. I have considered downloading a 2D cad programme, but I don't think I would get much use out of it as I don't need detailed drawings. Dimensioned sketches will do me, and good stl files to produce 3D prints.

12 April 2023 at 21:07 #641094Nigel Graham 2

Participant@nigelgraham2Thankyou Andy. I'd guessed you have a more powerful version than I do.

'

Lee- not sure if TurboCAD is "better" at 2D than 3D but it's certainly easier.. The Users' Forum Gallery is full of superb 3D images, some more art-work than design drawings, so the higher-rate editions are not lacking anything. It does date back to when AutoCAD had much of the field to itself, with the 3D modelling capabilities built later, though.

AutoDesk is AutoCAD's maker, also that of Fusion 360 and a variety of other, more specialised CAD goodies; all very much industry-only. Its own website says all its products are subscription only. Full AutoCAD (2D and 3D) is nearly £2000/ year but a cheaper 2D only version is also sold. Fusion 360 is presently on offer at just over £400 / year for its 3D CAD / CAM / PCB facilities ! I don't know what gives the huge price disparity, and this to commercial users.

However, we can, it says of F360, have:

For personal, hobby use

Fusion 360 for personal use is a limited free version that includes basic functionality.

What this means in range of functions I don't know, but it might exclude the CAM and other aspects.

I do have a copy of AutoCAD 2000 on CD, but have not tried more than a cursory look as I had even less idea about CAD when I was given it with no literature. I might try again, on my XP computer, out of interest. Some of the TC 2D-mode commands might be similar; and it may be what D.A.G. Brown used when he wrote his CAD primer.

AutoDesk boasts about "cloud based" and all that. I once asked our works IT manager if a company like ours, making marine security equipment, would consider any such software. I knew it used SolidWorks on PCs on a very heavily protected system. He laughed and replied, "Not likely! ".

Edited By Nigel Graham 2 on 12/04/2023 21:08:18

12 April 2023 at 22:08 #641104Nigel Graham 2

Participant@nigelgraham2Nick Wheeler –

Sorry, somehow I missed your explanation of how you drew the engine.

Thank you for showing it – it is a very interesting description although I am not familiar with Fusion's methods and terminology. I am impressed, and do respect your ability there.

It will be interesting too, to view progress on building the actual engine.

I'm a bit puzzled by your last paragraph though, about not needing orthographic drawings, and their "compromises" (which are?) for making many of the parts. Does that mean you can simply split the drawing into component parts and dimension them for workshop use, still in 3D model format? Or can you use CAM methods needing only the appropriate files?

12 April 2023 at 23:01 #641111Nick Wheeler

Participant@nickwheelerHow can a 2D representation of a complex 3D object not be compromised? That's true whether it's of a view from the top of a hill or parts for a toy train. Written descriptions of the same things would be equally compromised.

As for the drawings, I suspect the only part I'd want on paper is the crankshaft, and that's mostly to get each bigend journal clocked correctly. Most of the rest of it could be dimensioned on the relevant face of each isolated part on the screen as needed without any extra work. Many of the decisions how to make the part are covered by how it was modelled originally, which is why I suggest that just chipping bits off a piece of virtual stock isn't the most efficient way of using CAD. These are just some of the reasons why the time spent learning the basics are a worthwhile investment; I couldn't do any of this in 2D, let alone on paper.

I don't have any need for anything more than the free version of Fusion; the main things I would gain would be to edit linked files in place, be able to work on more than ten files at a time(you can change the ten you want so it's annoying instead of a problem) and more advanced CAM. I don't currently have a CNC, so that last one isn't even an annoyance. Fusion's files don't have to be stored in the cloud, and my weird stuff is of no use to anybody else. But the cloud basis is an excellent reason not to use it commercially.

I still think the barriers you struggle with are because it doesn't work quite the way you think it should and don't have anyone to give you the jolt needed to get around that – like thumping an old TV when the picture started to roll. The same might apply to me with Turbocad, as I struggled with it on and off for years without producing a single usable piece of work. Many other users, including you, report the same problems. Some of those are simply down to the complexity and power of such programs; I can't do complex stuff in Word for example as I've never needed more than arranging a few paragraphs.

13 April 2023 at 08:54 #641122IanT

Participant@iantI was a twenty year+ user of TurboCAD 2D and was very happy with it. I would have been delighted to have been able to migrate to 3D CAD using TurboCAD and surely that would have been the logical route to take?

However, I found TC extremely difficult to use in "3D mode" and finally accepted that either it wasn't capable of what I wanted of it – or – I simply wasn't capable of learning how to make it do so.

I now have 3 years of Solid Edge under my belt and have absolutely no regrets on making that choice. SE has been a very good investment of my time and effort.

Regards

IanT

13 April 2023 at 11:04 #641138Nigel Graham 2

Participant@nigelgraham2Nick –

Sorry, I don't see what you mean by "compromised".

I can understand you are able to make your own projects from your own isometric (3D) CAD drawings appropriately dimensioned. Some use only rough paper sketches, not "technical drawings" in any formal sense. Fine, and it does not matter in which order you make the individual parts, only the assembly order.

An orthographic elevation or plan view is not a "compromise". It is exactly as its subject is seen square-on: a coffee-mug seen horizontally across a table is a rectangle, but a circle when seen from above. They are not compromises but their physical appearances.

The engineering and architectural industries have used both orthographic and isometric drawings – first by pencil now mainly by CAD – world-wide for the past two or three hundred years without problems!

Similarly an Ordnance-Survey map is an orthographic plan view of the land; but has markings to show physical relief, from which you can plot sections, and calculate gradients and slope-lengths.

.

I do take your point about complexity though. I know 'Word' and 'Excel' enough for my needs, and even wrote a book manuscript on an Amstrad word-processor (different OS); but have never used these programmes to their fullest extent. That's not by difficulty but by need. My most advanced 'Excel' use was polar graphs ('Radar Charts', MS called them); cursing the designers for calling 0º and 360º two separate points and not giving proper editing tools! I had to plot negative radial values from 0 downwards, against angles of 5º, often only 3º, increments.

TurboCAD similarly has a huge array of tools not relevant to the hobby of model-engineering as it is aimed in one package at professional architects and engineers; but my problem is of understanding the relatively few, more basic ones we do need. Perhaps not its basic "Deluxe" editions, but certainly the more powerful 'Professional' and 'Platinum' editions would allow you to draw your car engine much as you did in Fusion; albeit in different ways.

I see how you created the crank-webs, and TurboCAD's Extrusion or Thickness tools will do similarly, but I do not how I would assemble their copies to depict the complete crankshaft. I'd need use careful co-ordinate arithmetic – not the "proper", reliable way to do it.

.

Ian –

Yes, my problem too! I tried Alibre Atom and later, SolidEdge, thinking they may be easier to learn; but they weren't. Also it seemed daft to start learning a totally new system when I had made at least some progress with TurboCAD.

None of it is the software's fault, and all my limited ability to learn it. The Deluxe edition I use does lack some tools you'd expect and which are in the more expensive versions; but it is still a very powerful 2D / 3D option system that allows a 3D-model-first approach to designing. In that respect it is similar to Sold Edge, Fusion and Alibre; but with very different ways to give the same results.

Only, I find those ways very hard to learn!

13 April 2023 at 12:36 #641143Nick Wheeler

Participant@nickwheelerPosted by Nigel Graham 2 on 13/04/2023 11:04:05:I see how you created the crank-webs, and TurboCAD's Extrusion or Thickness tools will do similarly, but I do not how I would assemble their copies to depict the complete crankshaft. I'd need use careful co-ordinate arithmetic – not the "proper", reliable way to do it.

the computer can do that arithmetic better than you, and it already knows where the bits are and how their geometry relates to other parts. So a joint is created by specifying which features(edges, holes, centres, points, specific custom requirements etc) on the two parts need to match. Next you offset or rotate them as necessary – two joined parts don't necessarily need to touch. Then you specify how you want one part to move(or not) around another, whether that's rotate around one axis and slide along another or other simpler movements. Finally you add the limits for how far it can move.

The centre of a circle will still be a viable connection even if you make it bigger or extrude the face another 5mm. That won't be true if you calculated how far apart the original parts were.

So my crankshaft has marked joint origins at the centre of each end of the main journals. These are then mated together, and the new part rotated 90, 180 or 270° as dictated by the firing order. And if you get that wrong, changing it just a matter of editing the joint to a new number.

13 April 2023 at 15:36 #641156Nigel Graham 2

Participant@nigelgraham2Yes, I know the computer is meant to do the hard work, and to extreme limits or accuracy and precision (I can never remember which is which!)

You and I though are using very different CAD programmes so although reaching the same results the tools available will be different.

I have not tried it physically but I gave the car crankshaft problem a lot of thought.

TuboCAD needs definite meeting-points, as does Fusion presumably, but if I were to draw one crank-web it has no sharp vertices to act as joint nuclei, and the centres of the pin and shaft would disappear. That is because it has become a single "solid" or a thin "surface" wrapped around a virtual cavity (depending partly on how I construct it, and there is nothing to tell which it will be).

Either way, it gains a single "Reference Point", the geometrical centre of the web's invisible, surrounding box; tangential to the curved ends and if the web is of constant thickness, hugging the two faces. That RP would be on the longitudinal centre-line of the web; but not central to the crank-throw because the ends are of different radii.

You can (but it never works for me) move the RP to become a common point in the assembly, but it needs a suitable Snap point to receive it… only our crank-web no longer has one. The shaft and pin centres have been subsumed into an entire unit, so are no longer in discrete cylinders. Your only hope is that the "corner" where the curved end meets the straight side will act as a vertex from where the web can be shuffled by distance-moves to its place.

Obviously there are ways to assemble the eight webs, 4 pins, intermediate bits of shaft and the end details, accurately and relatively easily – but I have no idea what they are.

There is a tool called "Assemble by axis" which allows concentric cylinders, cones etc to be put together, but I don't know if it would work here, and anyway it is not given in my edition of TurboCAD!

.

Similarly when we come to wrap the big-ends round the crank-pins: the shaft no longer has discrete axes or vertices to which the connecting-rod can be linked. Again, it is obviously possible – this is a full-scale industrial CAD system after all – but not at all obvious to me.

It seems to me I'd have to draw the crankshaft element by element from one end, being careful not to Add or Subtract any one from another until it is finished, because those Boolean changes are among the operations that turn the two affected entities into one solid (or "surface"

.

.It's also fatal to try to separate such a solid / surface into its original shapes. Cylinders are actually umpteen-facetted prisms and any of many possible false moves will disintegrate them into their individual facets. Unless you promptly use the "Redo" editing command to cancel the move anyway, they cannot be re-assembled.

.

I have drawn the crankshaft for my steam-lorry engine and added the eccentric sheaves, but orthogonally, so it was easy to put together. It's just rectangles in front elevation, rectangles and circles in end view. Even if modelled in 3D I'd still need the elevations because TurboCAD does not seem to dimension 3D models. A coloured 3D drawing requires great CAD skill but without dimensions it is useless in the machine-shop!

Instead TurboCAD uses its desperately difficult "Viewports" system. Though mainly for transferring the image from screen to paper, it can also create dimensioned 2D elevations from your selected orthogonal views of the 3D model. If you can drive it correctly it even keeps the dimension values irrespective of scaling the image itself to the paper that fits your printer. I did not have that model so just printed the 2D drawings.

My crankshaft can certainly be drawn in 3D, plus the rest of the engine, in fact the whole vehicle, in TurboCAD. However, though I had originally hoped learning such advanced techniques, modelling even just that single, simple two-throw crankshaft in 3D is for the experts, not lesser mortals like me!

13 April 2023 at 15:52 #641161

13 April 2023 at 15:52 #641161lee webster

Participant@leewebster72680Hi Nigel,

I am going to struggle wording this. There are words inside my head, but whether or not I can get them into some order is the thing.

Do you need 3D to show you what an object would look like, and how it would interact with other objects that make up a whole. Like a crankshaft and its con-rods for instance? Or do you need a cad programme to design the single entities within a construction from which you can determine where they need to be to fit properly, and to which you can add or construe dimensions?

Sometimes when I draw something and then draw something else that would interact with it, I.E, a crank and con-rod, I will draw the crank then discover it needs to be in a different place or size to accomodate the con-rod or piston or crankcase, all of which can change the crankshaft.

As I said earlier, words in my head, but making sense of them is another thing!

Lee

13 April 2023 at 17:02 #641168Nigel Graham 2

Participant@nigelgraham2I see me as the machine's designer, the 3D model helping me design it, the elevations from that to guide making the parts.

The value to me of a 3D model is that of helping ensure things do fit and work together: I decide the dimensions but then assemble them pictorially basically to ensure the dimensions are right.

Its main purpose would be then as General Arrangements, of sub-assemblies if not of the entire thing.

For example…

I am part way through trying to lay out the transmission for my steam-lorry: vertical engine directly driving a 2-speed gear that encloses the driving chain-sprocket. The engine location and the chain run are set – in fact I made the back axle years ago although it still needs completing in details.

The drawing of that area of the chassis is orthographic but if I could model in 3D it would make it easier to see just what lies where, and what room is left for such things as the boiler feed-pump and plumbing. Also, because a miniature steam-wagon five feet long is an awkward so-and-so to operate, where to put the floor cut-outs for the driver's feet!

The engine is partly located by the crankshaft and the cylinders; and the nearside end of the crankshaft has somehow to drive a simple (?) gear cluster and the pump. Its short off-side end holds the flywheel, which in turn has to avoid the steering-gear and wherever my foot-rest decides to go. This lot is further constrained by the tapered portion of the chassis, necessary for the Ackermann-steered front wheels' clearance. Oh, and the hand-brake gear needs live down there somewhere too.

(Such as it is: the brakes on the original were crude to say the least; just a curved steel pad pulled against the smooth, solid steel tyre of each hind wheel.)

There are no drawings for this thing! I can't ring up Blackgates or MJ Engineering, bank-card in hand, and buy a plan set. All I have is some old photos of the prototypes and rough idea of the leading dimensions, I started it long ago, have spent far too long with many major interruptions, and have to "design" it as I go. That often means correcting design errors built in ten or twenty years ago; and even re-making parts within months: the ash-pan now on there is Version 3.

My impetus for buying a CAD package was to help this project, and I bought TurboCAD simply because it was the only proper engineering CAD system available to model-engineers at the time.

I have tried a 3D model of the vehicle but it became too difficult. I could not draw the wheels properly, and had to omit the springs and steering. I'd' also omitted things like the seats and engine casing, which are just 3 rectangular boxes.

13 April 2023 at 19:40 #641183blowlamp

Participant@blowlampNigel.

I've put together a little video of one way you could make a simple crankshaft in MoI. I used a few of the tools in MoI to give an idea of its ease of use. To Copy the crank web I pressed CTRL whilst holding & dragging the left mouse button and to rotate the 3D view I held the right mouse button.

I can't see how 3D modelling could be much easier than this, especially for the way you say you want to work.

MoI is $295 and is yours forever – no cloud storage and no mandatory updates. New versions seem to be released every 3 to 4 years and currently cost $100 for the update

Martin.

13 April 2023 at 21:07 #641190Nigel Graham 2

Participant@nigelgraham2Thankyou Martin,

but the rigmarole the system demanded, put me off. I didn't know what I would be letting me in for by signing up to this, that and the other. So I have not seen the video.

However I believe your judgement of MoI. I have seen the initials bandied about but I failed to find out anything about it. There are YouTube videos demonstrating it but the retailer's web-site appears to be out of action. (I practically gave up on Yewtoob after Google ruined it!)

I should add I cannot learn anything from videos. They seem to be of experts doing difficult things easily, not instructing me how to do them myself.

'

I am wary of trying CAD systems new to me because I would have to learn them from scratch, and I have already made some progress with TurboCAD, which cost me good money. I have probably reached my natural limit with it, but equally probably I'd advance no further with any other make.

If I try anything else it would probably be Solid Edge (CE) again, while bits of it are still in my mind. Its problem for me was its own tutorial exercises do not form the continuum they are supposed to be. Also, they do not explain arcane Siemens concepts like "synchronous" and "ordered", in Siemens-speak (not their real meanings).

.

Perhaps 3D CAD modelling is too hard for me, but I can use TurboCAD in 2D mode just about well enough for my own use. Although it still needs care because IMSI seems to try make you use TurboCAD in 3D mode.

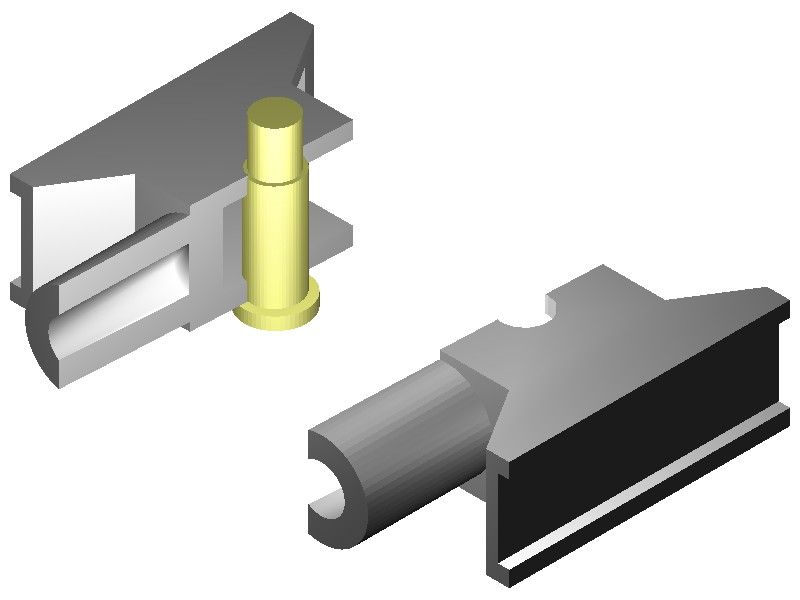

The 3D stuff is still there, if I want to try again at some point, or for simple, rather rough pictures like this, in TC 2019 Deluxe, of one of my steam-lorry's cross-heads. I had designed them from raw castings I'd bought on a rally stall, and drew them orthographically. I made this rendering separately, much later, after making the real parts.

13 April 2023 at 21:22 #641191blowlamp

Participant@blowlampPosted by Nigel Graham 2 on 13/04/2023 21:07:07:Thankyou Martin,

but the rigmarole the system demanded, put me off. I didn't know what I would be letting me in for by signing up to this, that and the other. So I have not seen the video.

However I believe your judgement of MoI. I have seen the initials bandied about but I failed to find out anything about it. There are YouTube videos demonstrating it but the retailer's web-site appears to be out of action. (I practically gave up on Yewtoob after Google ruined it!)…

That's completely amazing.

13 April 2023 at 23:35 #641200

13 April 2023 at 23:35 #641200Nigel Graham 2

Participant@nigelgraham2Ha-bloomin'-Ha….

It took me a couple of goes to work out what to press to start the video, as I had been selecting the title and that opens the 'Vimeo' host – or whatever 'Vimeo' is – hence my comment about accounts.

Yes, MoI looks simpler than TurboCAD would be to draw that same crank, but I could not follow most of it. It was too fast for that. Like all such videos it is of some bloke, Eddie Walker here, rushing through what he finds easy.

I tried to watch how he placed the tangential sides of the web, and the crank-pin on its centres on the webs, but it was all too quick and flashy, and the drawing had no obvious snap points or equivalents.

'

However I would gain nothing by trying to change system now. I would have to start learning the new one right from scratch, and fear I would spend more time trying to learn to use it, than using it.

.

I spent a while this evening trying to model my lorry wheels in 3D. The cylindrical hub carries two flanged steel plates (welded flanges: the originals were probably pressed), slightly coned, surrounded by a thick shock-absorbing (says the patent) inner wooden tyre, and plain steel outer tyre. The plates, 2mm thick on the model, are rose-pierced: 6 triangular holes with rounded corners.

I started the drawing with the hub, some distance across the TurboCAD "Model Space" from the 3D model of the vehicle itself.

It took a while to place the shallow spigot on each end, to locate the plates, by co-ordinates that seem to keep drifting, the lack of snap points and continual work-plane problems. The real hubs had been basic turning.

Unable to plot the dishing, I decided to leave the plates flat in the drawing. I had dished the real ones quite easily, by screwing them down to a jig before welding their flanges on.

One plots the 6 cut-outs by drawing just one as a polyline, thickening it, radially copying it then subtracting them all from the disc. Rather than trying to drawing the master one with rounded corners, I chose to leave them sharp, as in clock wheels. Even then I was unable to keep the construction-lines on the same plane no matter what I did, so they would not intersect in all 3 dimensions, so could not work. The real steel discs had been easy to mark out and drill on a rotary-table.

Fruitless. I closed the file without saving the changes.

It had been easier to draw the wheels (12.7" dia rear, 10.5" dia front) on paper, and make them, than to model them in 3D CAD!

I've wrecked my A0 drawing-board stand by dismantling it, thinking I would never need it again…. Oh dear.

14 April 2023 at 00:44 #641201blowlamp

Participant@blowlampPosted by Nigel Graham 2 on 13/04/2023 23:35:36:Yes, MoI looks simpler than TurboCAD would be to draw that same crank, but I could not follow most of it. It was too fast for that. Like all such videos it is of some bloke, Eddie Walker here, rushing through what he finds easy.

I tried to watch how he placed the tangential sides of the web, and the crank-pin on its centres on the webs, but it was all too quick and flashy, and the drawing had no obvious snap points or equivalents.

That bloke Eddie Walker (don't ask), was actually me. I made the video to try and help you get into 3D modelling in an easy way.

I suggest you watch the video at full size (click the 4-arrow icon next to the V in the lower right corner) and pausing playback might help too.

With regard to the tangential sides of the web. If you look carefully you'll see small visual hints appear onscreen, such as Tan, Perp and Int etc. Whenever these are visible, they indicate how the line you are drawing will be attached – so if you're drawing a line roughly tangential from one circle to another, Tan will be displayed at the intersection of both ends of the line and a perfect tangent will be made. This is how I attached the angled sides of the crank web to the small trimmed circle – look for Tan & Int while I'm drawing these angled lines.

You will also see small crosses (x), which are snap points, appear on parts of the model as the mouse pointer nears them. You can attach lines, curves and solids to these points just by placing the mouse pointer over them and clicking – you can drag items to them as well.It's simple and powerful.

Also, clicking the onscreen Help button takes you directly to the reference of whichever tool or function you have selected. Very handy.

There's an easy to use (90day) download here. if you are interested.

Martin.

Edited By blowlamp on 14/04/2023 00:46:35

14 April 2023 at 07:05 #641207 JasonBModerator@jasonb

JasonBModerator@jasonbNigel not that it wil do anygood as we just end up with the same discussion every couple of months that we have had now for a few years but along the bottom of the Vimeo screen is the common "cog icon" used for settings click that and you will be able to adjust playback speed just as anyone else can on Youtube etc though not sure it will go slow enough

14 April 2023 at 09:36 #641224

14 April 2023 at 09:36 #641224 JasonBModerator@jasonb

JasonBModerator@jasonbAfraid another video for you, use the "cog" icon bottom right to set playback speed. This is a similar shape crank to what Blowlamp shows done in Alibre and I also go on to assemble it as a 4 throw crank and briefly produce a 2D drawing at the end. Couple of pauses as the screen recorder was slowing things down

Bit different to MOI but the basic principals are the same just stacking up simple 2D shapes each of which is extruded to give the 3rd dimension. Mirroring and using the same items multiple times makes quick work

It is a pity there is nobody on the forum with the same version of AC that you have it would be good to see someone draw the crank, even in a better version it may give you some guidance. Can you post a picture of the wheel as it doe snot sound too hard to draw, either an original or what you have made.

14 April 2023 at 10:28 #641232 JasonBModerator@jasonb

JasonBModerator@jasonbWheel

Hub – simple 2D half section mirrored and then rotated about central axis

Disc – dishing best dealt with by drawing a section and then revolving. Cutout fillet shown being added to the 2D shape and also directly to the 3D model to show both methods. Bolt holes simple circle and circular pattern

Wood rim and tyre just two circles extruded.

All 2D sketches done on basic planes or directly on an existing surface so no worries about line snot meeting up

Assembly mate faces, concentric constraint to a bolt hole and central axis

Edited By JasonB on 14/04/2023 10:30:30

14 April 2023 at 10:52 #641239Nigel Graham 2

Participant@nigelgraham2Thank you Martin.

I was a bit puzzled about the video's author after you has said something having putting it together!

I did notice the snap points appear at times, but although I was watching it carefully probably missed some of them.

'

Thankyou for that tip Jason, about video speeds. I'd not known that as I rarely watch videos – of any sort.

EDIT inserted here: Sorry – your two videos appeared after I had written and posted this so I have not yet viewed them. I see you use the word "constrained" at one point. I know that is a definite CAD term but one not used in TurboCAD, which may have some equivalent under another name though. You also refer to mirror copying: that is available and the whole wheel could be modelled that way because all four on my engine are two fully symmetrical pairs. (I have put the differential and chain-sprocket on the axle inboard of the spring, Foden style, not on one of the wheels as a photograph obtained years later suggests was original.) Nor does my edition of TC have the fillet tool available in the more expensive editions.

'''''''''''

For instruction manuals, I prefer static forms (printed or pdf displays), as came with my copy of TurboCAD 2019 (CD), and as Siemens uses (web-site). Or indeed of course, the MEW introduction to Alibre.

This is only partly having been put off videos by their presentations, an on YouTube by the childish advertisement breaks.

My main reason is that I can follow static steps at my own speed, and can easily look back if necessary; although it is awkward using both a pdf document and the exercise itself on a single screen.

You joke about my being slow to learn CAD. It's not just CAD. It is anything, especially academic; and always so despite an early clinical assessment of unusually high IQ (says my NHS records – surely a measurement error!).

I also grasp topics within each field in an oddly, randomly but rigidly compartmental way. So for example, despite having drawn that sectioned cross-head as I did, I might not be able to use whatever is necessary to give it the connecting-rod.

Just as in Maths, I can understand 3D graphs but never matrices – though there is a significant difference. 3D graphs can, and CAD models do, both depict real things whereas matrices are pure abstractions with no real-world meanings.*

Hence my needing a fixed, step-by-step approach I cannot find in a video, gears or not, even in 1st gear & low-range 4WD.

.

Many my early 3D attempts were basic exercises I invented to explore just two or three tools at a time, such as joining two rectangular blocks together and putting holes of set sizes in set locations through them. The cross-head was another exercise: I'd already made the real ones! Someone suggested using components from published plans as exercises – a good idea because if the elevations derived from the 3D images then match the original, orthographic drawings the CAD model must be right!

.

*(I know Matrices have found a real but very arcane use. They are in computer programmes solving vast volumes of extremely advanced calculations in certain dynamic stress and vibration analyses; but that is all for professional specialists at PhD level and above. Such as the Doctor of Mathematics who tried to help me understand them. So I am very surprised matrices are where I first heard of, and was baffled by, them as mere puzzles in the GCSE school maths syllabus I studied in evening-class about 30 years ago.)

Edited By Nigel Graham 2 on 14/04/2023 11:24:21

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Morse Key

Started by:

Steve Withnell in: Work In Progress and completed items

- 3

- 3

-

5 April 2025 at 18:20

Mike Hurley

-

Stripped aluminum threads. Now what?

1

2

Started by:

brucemc777 in: Beginners questions

- 19

- 34

-

5 April 2025 at 17:51

brucemc777

-

How to wire up 3 phase motor and 3 phase converter?

Started by:

ell81 in: Beginners questions

- 7

- 14

-

5 April 2025 at 17:16

Emgee

-

Flattening brass plates

Started by:

t1krt in: Workshop Techniques

- 4

- 4

-

5 April 2025 at 17:15

bernard towers

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 14

- 286

-

5 April 2025 at 16:00

Phil Whitley

-

Problem getting the right parameters on a VFD

Started by:

Robert Graham in: Electronics in the Workshop

- 5

- 6

-

5 April 2025 at 15:24

David Jupp

-

Myford S7 Taistock Adjustment

Started by:

Harry Wilkes

in: General Questions

Harry Wilkes

in: General Questions

- 9

- 12

-

5 April 2025 at 15:17

Harry Wilkes

Harry Wilkes

-

James Coombes Drawing Error (or mine?)

Started by:

Steve Withnell in: Drawing Errors and Corrections

- 4

- 5

-

5 April 2025 at 10:51

Steve Withnell

-

Measuring increments on boring head

Started by:

Bill Phinn in: Workshop Techniques

- 15

- 18

-

5 April 2025 at 08:48

Bo’sun

-

Flexispeed Meteor 2

Started by:

ferroequinologist in: Manual machine tools

- 11

- 19

-

5 April 2025 at 07:01

ferroequinologist

-

What Did You Do Today 2025

1

2

3

4

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 23

- 78

-

4 April 2025 at 20:57

Nigel Graham 2

-

Powered hacksaw – blade lift for the return stroke

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 17

-

4 April 2025 at 20:00

Nicholas Farr

Nicholas Farr

-

Damp proofing concrete floors

Started by:

Duff Machinist in: General Questions

- 13

- 13

-

4 April 2025 at 19:57

Bazyle

Bazyle

-

New member old lathe

Started by:

t1krt in: Introduce Yourself – New members start here!

- 8

- 16

-

4 April 2025 at 19:52

t1krt

-

Elliott Omnimill Quill Clamp

Started by:

dangermouse in: Manual machine tools

- 3

- 3

-

4 April 2025 at 19:23

Bazyle

Bazyle

-

Tangential tooling

1

2

Started by:

Keith Matheson in: Workshop Tools and Tooling

- 13

- 29

-

4 April 2025 at 18:14

Howard Lewis

-

Which lathes have drawbars in the headstock?

1

2

Started by:

ell81 in: Beginners questions

- 17

- 26

-

4 April 2025 at 18:04

Howard Lewis

-

gear cutting with the shaper

Started by:

jacques maurel in: Workshop Techniques

- 5

- 6

-

4 April 2025 at 15:15

Andrew Tinsley

-

Machinery Handbook

1

2

Started by:

Dalboy in: Books

- 30

- 37

-

4 April 2025 at 12:27

SillyOldDuffer

-

Electric motor vibrations

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 12

-

4 April 2025 at 07:38

JasonB

JasonB

-

Build Your Own Metal Working Shop From Scrap (7 book series)

Started by:

Dr_GMJN in: Books

- 6

- 7

-

4 April 2025 at 06:39

Pete

-

Scraping

Started by:

ryan.carter848 in: Books

- 7

- 10

-

4 April 2025 at 05:11

Pete

-

Ml10

Started by:

keel in: Beginners questions

- 5

- 7

-

3 April 2025 at 23:06

duncan webster 1

-

Warrington Model Engineering Developments

1

2

Started by:

colin wilkinson in: General Questions

- 14

- 41

-

3 April 2025 at 20:26

keel

-

Vice as Broaching Press

1

2

Started by:

James Hall 3 in: Beginners questions

- 16

- 37

-

3 April 2025 at 20:00

JasonB

JasonB

-

Morse Key

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Morse Key

- Stripped aluminum threads. Now what?

- How to wire up 3 phase motor and 3 phase converter?

- Flattening brass plates

- My week this week! My workshop videos

- Problem getting the right parameters on a VFD

- Myford S7 Taistock Adjustment

- James Coombes Drawing Error (or mine?)

- Measuring increments on boring head

- Flexispeed Meteor 2

.

.