Regular readers of the forum may be familiar with my thread on my interminable attempts to build a steam engine, to be found here.

It ended on a high note with me reporting that the damnable thing actually RAN – on air mind you, but it ran.

I wasn't particularly happy with how it ran though, it would not start on its own and could easily be stopped with a little drag on the flywheel. I left it alone for a while, though, whilst other things grabbed my attention (illness, retirement, house sales (in process) – dull stuff).

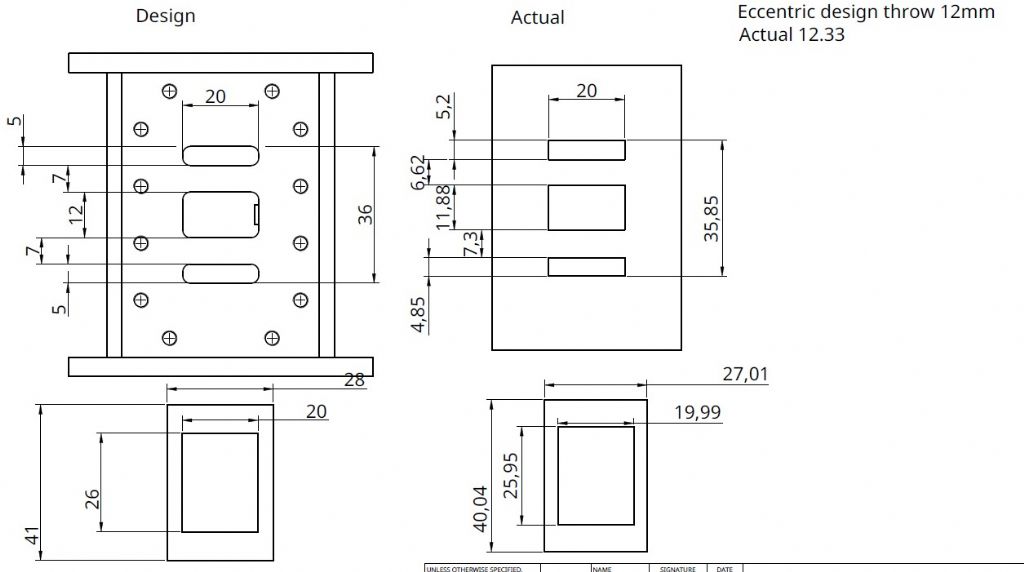

Now retired (HOORAH!) I'm having a look at this again. I've gone and measured up what I've built and compared it to what I designed and then again, compared it to what I intended to design – and found, um, discrepancies.

I throw myself on the mercy of the court.

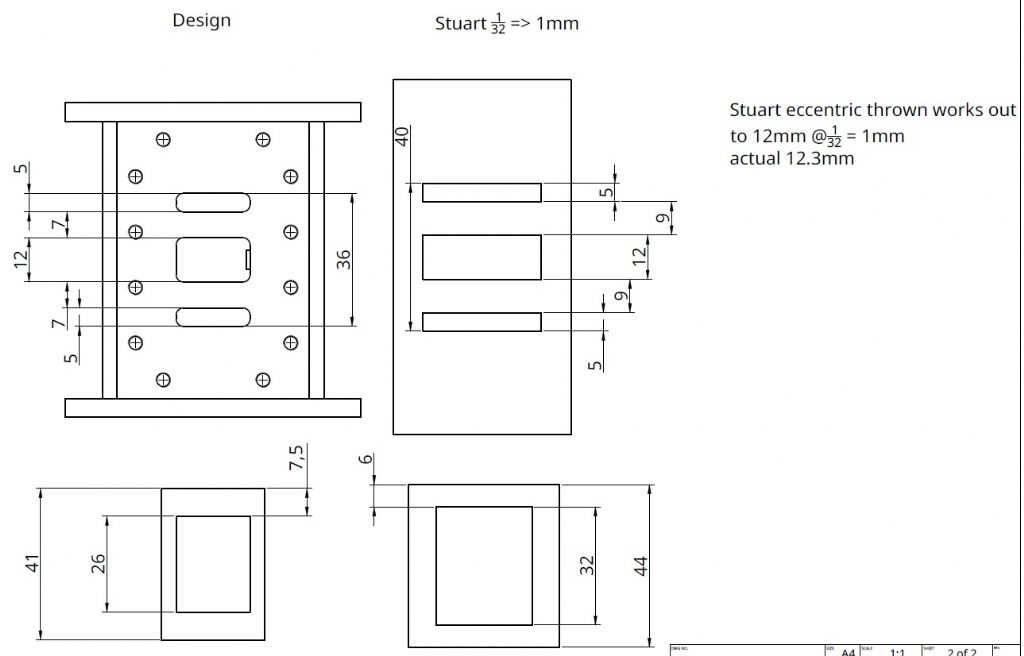

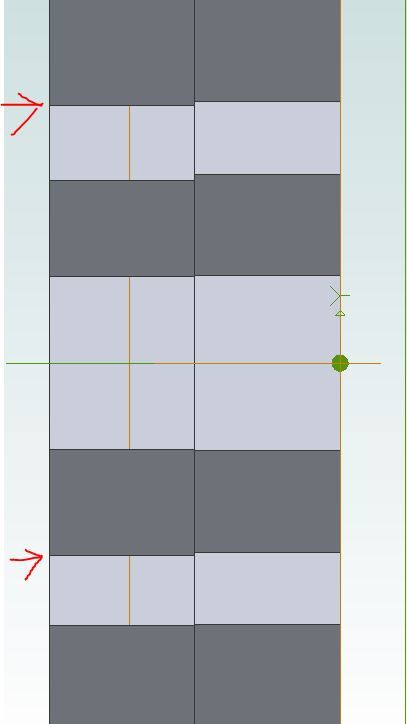

So the basic port geometry was taken from a Stuart 5A. Specifically I scaled up so that 1/32nd inch = 1mm. No way was I translating to metric directly!

Now I come to have completed the work, I see that the way I've drawn the ports doesn't directly map to the Stuart design. It's possible (though rather unlikely) that I had a reason for this and it wasn't just a mistake. If anyone could suggest a deliberate reason for the change I would happily pretend it was true and claim intent…!

As you can see from the above, the port widths are a good match for the Stuart, but the separations are wrong.

To add insult to injury, The implementation of the drawings is a little out.

Clearly, that's entirely on me!

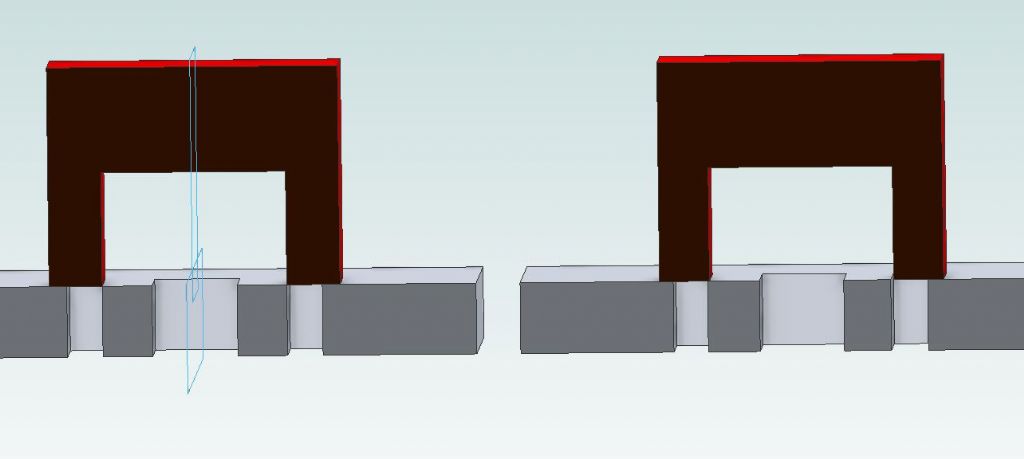

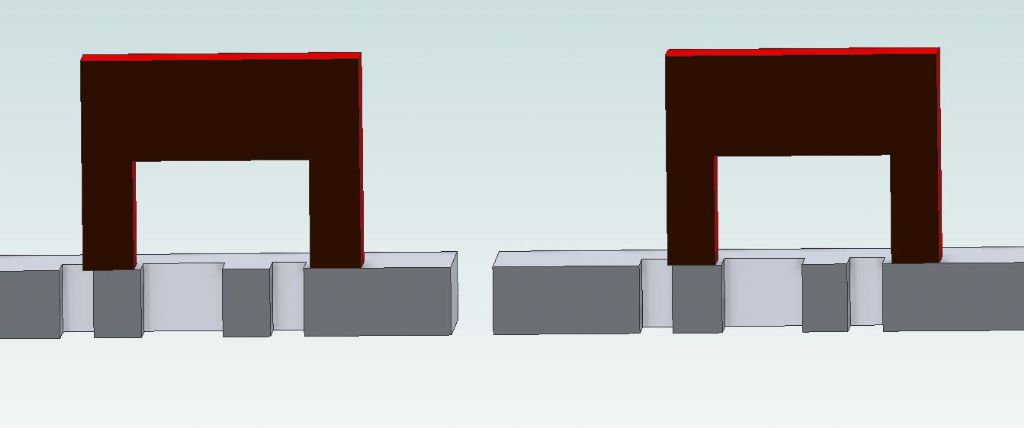

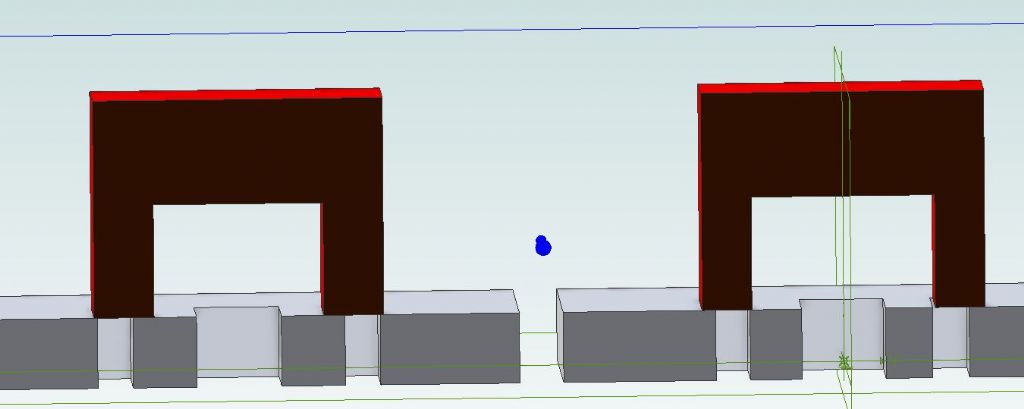

Whilst I would be delighted if I could make this work by some simple trick, I think what I will need to do is something like this.

- Mill out the centre of the chest. The ports are around 5mm deep and the height from the top of the chest to the cylinder wall is around 12.5mm, so I should have plenty of 'meat'

- Carve out a block of cast iron to fit closely in the resulting space.

- Glue it in place.

- re-mill the ports according to the (new) design.

- smooth off the new surface (fly cutter probably)

- Make another D Valve.

If there are alternatives (ideally featuring less work – and not involving remaking the eccentrics  ) I would be most interested.

) I would be most interested.

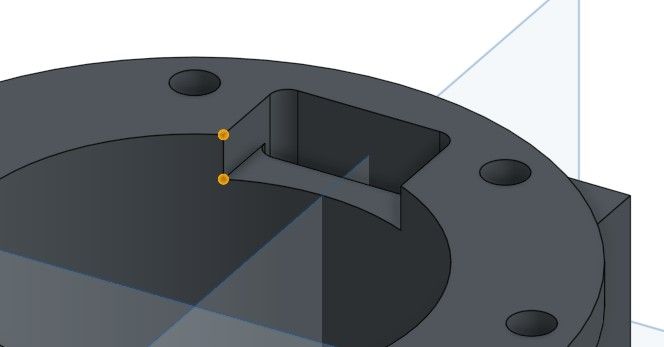

For this I have two questions, I think. One. the glue. Whilst it's entirely possible that this will never run under steam, it may, so I would like to pick a glue which would stand steam. I also wasn't sure if I should pick a high viscosity one like JB weld or if something thinner was more appropriate. What would you recommend?

Second question; Should I mill down to the level of the current base of the ports so the glue layer would be at the port level, or should I mill below the current port depth which would leave a layer of iron at the base of the new ports?

Well that's the end of my dark confessions – any help as always will be appreciated.

Iain

Iain Downs.