"Contact the army or similar and tell them you have a challenge for one of their larger helicopters."

Yes, well mmm?!

Story from times past, possibly apocryphal …

One of our 'sister' S&R flights was based on an ex WW2 airfield which retained the reinforced blast walls of the time. The operational Standby aircraft (Whirlwinds) were parked in these areas and had had rotor start-up problems (blade-sailing) in windy conditions. Local permission was granted to get 'Works and Bricks' to remove the walls. Local Boss had a whizz idea – get the local TA chaps to blow them up as a training exercise – they were obviously good with noise makers and stuff!! Duly arranged and LB asked TA Chief if they wanted aircraft moved during exercise.

Duly arranged and LB asked TA Chief if they wanted aircraft moved during exercise. Not necessary, says TA Chief

Not necessary, says TA Chief

Holes drilled in walls, explosives inserted, packing to complete etc. , retire to safe distance, BANG!! … Wall remains intact, S&R Standby aircraft, now with broken oleo, mucho collapso

It WAS a long time ago and nobody would do such a thing nowadays, would they??

rgds

Bill

Mark Prickett 2.

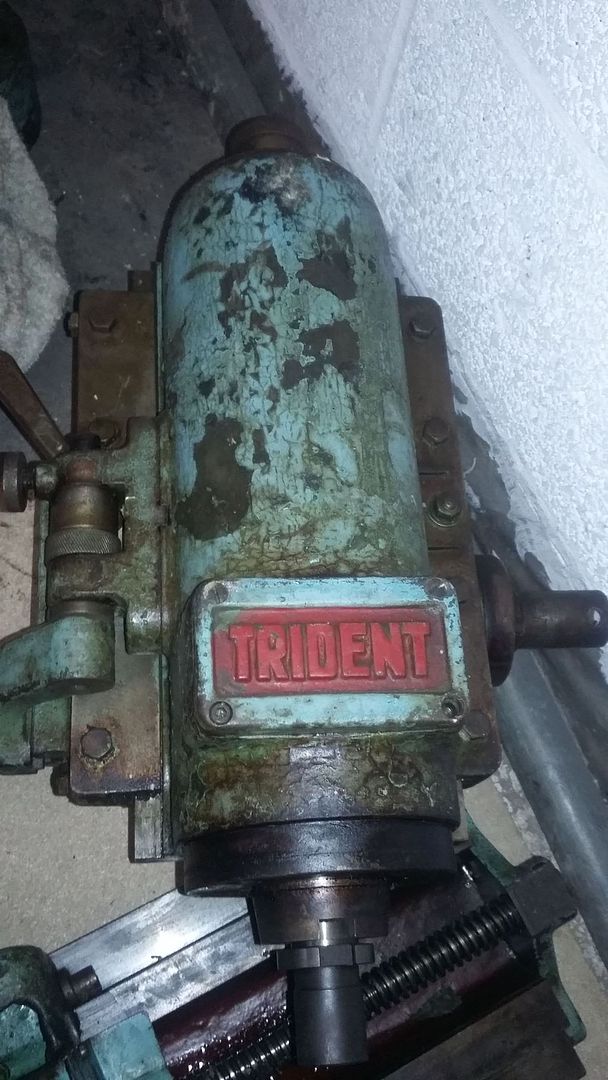

A real vert. miller and OTT for home use unless I went into drop forge die sinking.

A real vert. miller and OTT for home use unless I went into drop forge die sinking.