I don’t know Gray.

If one is talking of finger wear, I’ve always adjusted the fingers. Line contact is theoretically best, but an arc is fine by both of us.

Curved tips and rapid wear. Agreed, but I have usually just attacked the tips with a file – to “reface” them. but I stress I don’t use them so much these days. I have never used them enough to have to replace the tips/blocks

Best solution – roller tips, if you can keep them small enough?

Heating – hopefully overstated because I let my coolant pump pour coolant over the fingers because mine are always that close to the tool . Also lubricates.

I think it depends on the job – the bog standard steady is going to be fine 99% of the time, and thats what the pros design them for – general purpose “slender shafts” if there is such a thing,

The problem I find is one of size when dealing with very slender shafts. Because then the shaft IS going to flex like hell, and the fingers are too big. So then I revert to this funny tool I got from Chronos, where you drill a hole in a blank held in the holder, and then move the cutter within this holder. (Having started the cut on a thicker bit of metal right up by the tailstock centre. Probalby telling my granny. -sorry – for a man making small engines. )

What I’m not so keen on is an externally fitted 4 point contact because then you lose the “self aligning/self diametering ” part of the setup. I don’t htink I have ever had chatter with a travelling steady – or if I have I have treated it as an indication that adjustment is out, because chatter is a small high frequency movement, and that as we all know is not possible with 3 points of contact. The implication being that one ain’t got the contact that one thought! I suspect thats a more realistic appraisal of the situation.

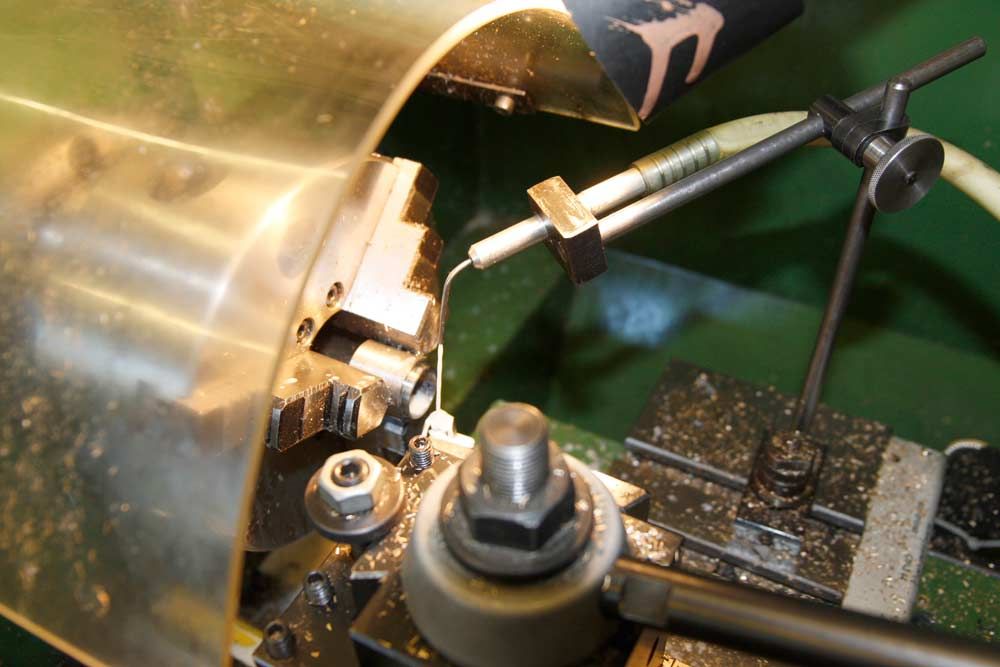

Back to heat. I do know that a lot of people cut dry or with brushed on coolant, to which one can only say that there are advantages in cleanliness, but you pays at other times, and tightly set steadies is one of the times one will pay. Take a choice? I have an Axminster cheapie pump, but a garden pond one is pretty good. Delivers through a 2mm dia vetinerary needle, and gives enough coolant to do a job, but doesn’t splash badly. So perhaps thats one way round the problem of heat, wear (up to a point) and chip clearance. (Flow regulator is a little steam globe valve.)

Edited By mgj on 18/03/2011 19:56:29

mgj.